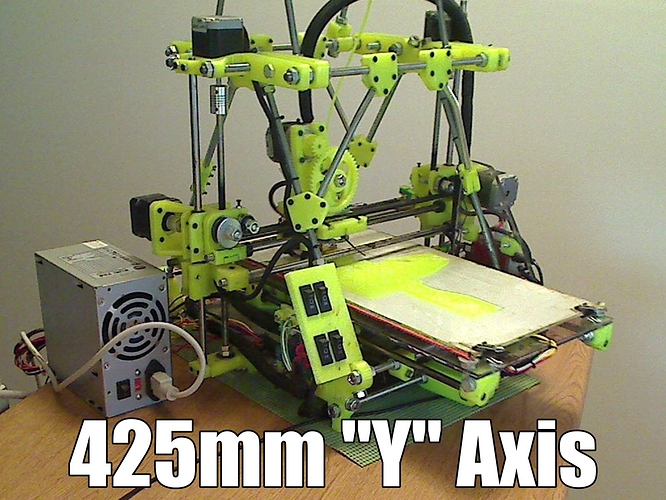

I got this modification uploaded to instructables: http://www.instructables.com/id/Long-Bed-Conversion-for-i2-3d-Printer/

with this conversion you can Print: {Long Bed Printer aka “Big Red”} http://www.instructables.com/id/Long-Bed-Printed-3d-Printer/

Don’t you think it’s better enlarge x axis??

Nice mod, Ive been using the 12x8 heated bed for a couple years now, but I put it on the x axis. It makes sense why you did it to the Y axis as there was less to change, but can I ask why your still using the outdated design? Thats ALOT of plastic and hardware to be moving. Stepping up to an I3 design will save alot of materials and weight.

Nice accomplishment - none the less.

Yeah, this is a particularly interesting mod since Mendel type architectures don’t scale well in Y  There are a lot of stability and moving mass implications to large moving beds, so if this works well, you must’ve done a good job with the mechanicals.

There are a lot of stability and moving mass implications to large moving beds, so if this works well, you must’ve done a good job with the mechanicals.

@Alvaro_Rey_Rodriguez Enlarging both X and Y without having a printer twice the size of the print bed is the final goal. X Axis is the easier change to make, so I wanted to find a way to increase “Y” Axis first, then do “X”.

@Jeff_Para The i2 has some advantages that i3 does not. a printer using the best of both, is the type of printer I am after. The printed printer is using the box frame design for “X” of an i3, and is working well. thanks of the feed back.

@Ryan_Carlyle The moving mass does not allow for high speed printing, with current printer. But being able to model and test large design elements with the printer keeps the cost down. This i2 has 900+ hours of print time with the larger bed and keeps going. thanks for the feed back.

Id like to hear the advantages then. I had one of those 4 years ago and like it was stated earlier its a difficult platform to expand - Good for you on being resourceful though.

@Nathan_Walkner The yellow printer has 100mm for “Z” and the Red printed printer has 140mm “Z”. Being on a small budget, you reuse what you have. Underpowered?? not sure what you mean. Either of the printers have not failed due to power problems. both have printed many 10 - 15 hour prints. I am using a good quality motors that may be a factor to power issues. thanks for the feed back.

@Jeff_Para Here are a few thoughts, the “Y” Axis direction of the i2 frame is much stronger than many of the i3’s that flop around without any triangular bracing along “Y”.

The “X” axis frame is stronger in the i3 compared to the i2. I did add the i3 box frame design into the Red printed printer.

The i2 carriage is strong in the side to side weak in the up and down. The i3 is strong in the up and down and weak in the side to side. Combining both i2 and i3 strong points into a triangular “X” carriage axis without loosing “Z” would make this area better.

Larger smooth rods for both axis would improve my design too.

Drop into hangouts, later one of the printers will be running.

Well the big problem with your design is unsprung weight on top. You wouldn’t NEED all that extra bracing if you moved the motors down to the bottom. When I started with the I2 That was the first mod I did - was to widen the base and move the uprights out 15 degrees. Again though - using threaded rod (which is NEVER straight) and all that hardware adds unnecessary weight as well. Why do you think the I3 design is now “the standard”? However, I am not a believer in the plate style I3 either. I agree with you on the flexing. I use in my designs the box style. But its not mounted the same way. Due to the flexing of threaded rod the Z would flex.

Thanks for the invite to hangouts, but I have been watching my I4 printing 8" printes for the last 13 hours - so I know what printing looks like.

Have fun!!

A problem with moving the motors to bottom, is the “X” Axis weight is transferred to the motor bearings. Motors are not intended to hold weight in this direction. A “something” to remove the weight from the motor and motors at the bottom would be good. I like your design of moving the uprights out 15 degrees, that would help stiffen the “X” weakness of the i2. In the irc and most rooms the i3 is the recommended printer for people to start with. i4?? heard talk about it but have not seen one yet. Got a link? oh, the extra braces help with the top vertex being widened, which allows the extruder to go out the top of printer.