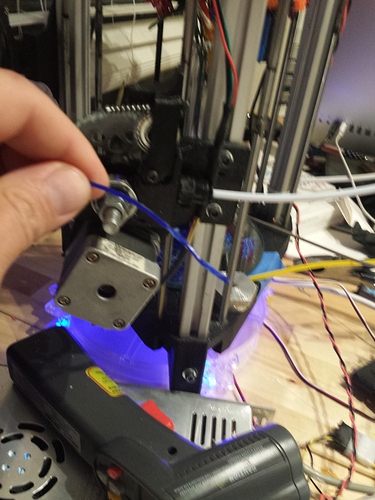

I don’t understand how this sucker can print for 4 to 6 hours without fail, but larger prints have a high percentage chance of failure, so that morning comes and I awake to this…retracts are going pretty well, I’ve successfully printed for a longer period of time, the Filament has been open for about a week and a half in a dry climate. If the extruder were gripping too tight, you’d think it would be failing all over the place, but it’s not.

Do your failure rates go up as your build size increases, or is it just me?

Just a guess, but it sounds like your extruder motor heats over time and transmits that heat through the shaft. After a while, it gets hot enough to soften the filament, causing the jam.

I’d try minimizing current to the motor first, then adding passive or active cooling to the motor/shaft.

This used to happen to me printing PLA all the time. I was about to give up, until I used vegetable oil on the tip of the filament and a sponge soaked in it. 2 days ago I successfully printed for 10 hours with no jams.

I can throw some cooling on it, but with the seperation due to gearing, is there really a path for heat?

(FWIW, I was able to continue the print…yeah, there’ll be a weak section, but it’s just a Tiki dustcatcher, so I’m not worried.)

Oh, and since I burned out the nozzle and heat break, the first step was to re-season with Canola

if you set up your machine properly. there is no time limit for your printing time. I have done 10+ hours without problems.

since 2 weeks I’ve trouble with my e3d hotend too (I assume you also have one). I’m not sure why. 300 hours printing with no problems and within a few days my printer failed every time.

I reduced the retract length from 5.5 to 4mm and now it’s working (for the moment)

I’m using 4.5mm and 40 mm/s as retract settings, based on Cura’s recommendations. I’ll shorten it a bit and see what happens.

40mm/s sure sounds a whole lot better for the printer than 150-200mm/s I’ve seen around here.

@Andreas_Holldorfer did this happen after you were using ABS? Because mine started jamming after I switched back to PLA after using ABS. But before that everything was fine.

my guess is that ABS coats the internals of the hotend with a thin layer that causes the jamming.

My retract is at 60 mm/s but I use a Nema17 stepper (1/8 micro stepping) at about 2Amps this thing has a lot more torque than the most common extruder out there and over 80 I’ve massive problems …

@Nuker_Bot_NukerBot_3 swithing between ABS and PLA is a sure way to get problems. the residues drom the two mix up in the hotend and cause trouble all over. there is a longer article about this in the German subforum at http://reprap.org. do yourself a favour and use different hotends for different sorts of plastic.

Would running a nylon job help clean out the ABS/PLA mess?

I am not sure. Burning the residue from the nozzle might work. At least according to a - quite old-video I have seen on youtube:

Extreme method, but might work.