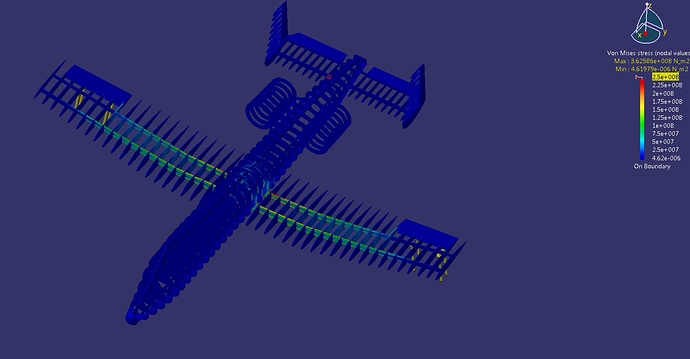

I did a A10 Plane Model intended for 3D Printing. Hopefully going soon for making it. The size would be around 200mm the wingspan (max dim) in a sinterization machine (ZCORP 450) which is available at the Fablab of Barcelona. Im not expert so if someone find a mistake pls tell. Im a little worried about the thickness, may I choosed too thin (0.3mm). If this value is under the minimum achieved the machine make it bigger?

http://www.thingiverse.com/thing:62519

0.3mm is one single layer. That won’t give any support whatsoever. You need at least 2 or 3 layers. There are some printers that support 0.1 layers. Then you might get away with 3 layers at total 0.3mm.

I don’t know the zCorp printer though…

Ok thanks I will check with the workshop about the layer thickness. It was a calculation mistake: I modelled thinking on a 3m span to make an RC on wood, later I scalled it for printing.

According the machine specs layer size is 0.15 mm, may works

There is no way that a zprinted plane will be light and strong enough at the same time to fly. Like @Jelle_Boomstra said, it uses gypsum powder and makes parts that are just as heavy and brittle as regular gypsum. Save your money (the prints are pretty expensive), and try to modify it so that a hobby-grade printer can create it instead.

Coming back to my original request: advices on how to modify the design for making it printable, on that printer, are welcome

Are you trying to make that plane fly or is it just for decorative purposes?

Originally I wanted do a bigger RC plane based on the same scheme, but this reduced one is just for fun

So it wont fly

Well, that makes it easier

I’d increase all thicknesses to at least 1mm, better 2mm, if you’re dead set on making it on the Zprinter. The ribs look like they are well suited for a lasercutter, which would be a faster, cheaper and less problematic way to make them.

Yes I plan to do it on wood laser cut, for putting two electric turbines and radio controlled, but the design will be different of course. At the moment I have no other machines on hand for 3D print. Thanks!

I will increase the thickness to at least 2mm, althought I would have to make the ribs more spaced

If anyone get it printed pls let me know if there are flaws. In parallel, I will redo the thickness of the model adding more meat as recommended above

James Dougan, may I ask you which part you were involved on the A10 for so long? Design development? Manufacturing? For sure was interesting

Following your advice I have created a Thicker version of the Model (1mm thick this time) http://www.thingiverse.com/thing:65541