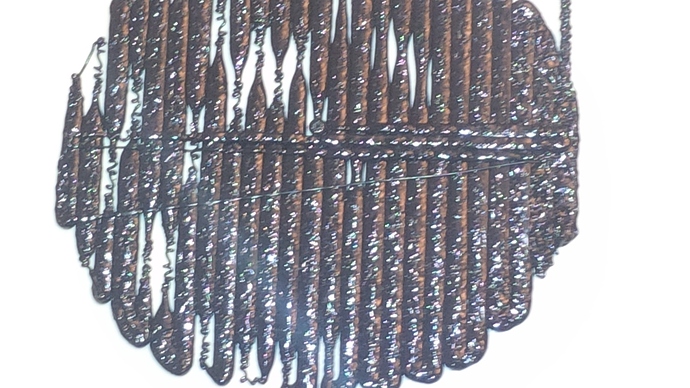

I could use some help! After a long hiatus, I’ve started trying to use my ToM again, and I’m getting terrible results. The plastic is, at best, coming out big and blobby with what looks like air-bubbles in it, but it is also often striping on the hobbed gear and thus not coming out at all, although it starts up again if I push on the filament a little. Attached are some pictures of a raft printed today.

Any ideas on where to start debugging this? I’m guessing the bubbles are because the ABS has absorbed too much humidity, but I Think I should be getting a thinner, neater raft than this, and I don’t know why the extruder would be so unreliable.

Feedrate and travel rate at 20, hot-end at 240C.

I had something similar with my PLA, turned out to be the feed bolt was clogged with old pla and was not grabbing the filament. The other option is that the head is too hot. Is it really at 240, is it reading okay? Is 240C a good temperature for ABS?

240 seemed hot to me, to be honest, but that is the replicator-G default. IIRC, when I was printing 2 years ago, I was going more for about 220 or so. I’m sure I saw something about how to calibrate the extrusion temp, but I’m having trouble finding old docs and howtos on makerbot’s site.

Plunger not tight enough against the plastic?

The bubbles are because your plastic has absorbed water and that water is now boiling out at extrusion temperatures. Get some new dry plastic or dry out what you have (low heat for a long time)

@Matthew_Wilson1 I was worried about that. Any suggestions on temp and for how long? I’m guessing I want something a little over 100C, for an hour or so?

@Nick_Tuttle I think I’m at the limit of what I can do on that front, but I can probably get more by changing the bolt (it has a section that isn’t threaded, limiting my travel), and/or a longer spring.

Hmm. http://www.printrbottalk.com/forum/viewtopic.php?f=74&t=633 has a poster claiming ~85C for 2 hours should do the trick.

The recommended drying condition for ABS pellets is 3 hours at 80C.

The lower you set your hotend temperature, the less inter-layer adhesion you’ll get. 220C seems low to me - i print around 240C with the first layer a bit hotter. Keep in mind that every hotend’s thermistor reads a bit different, so your 240C might be someone else’s 220C (or the other way around).

I’ve been using an old food dehydrator, I’ve also heard that a lightbulb in a box works. If you get too close to the glass transition temp of the ABS it will soften and all stick together (don’t ask how I know) so the 80C - 85C range sounds correct to me.

You sure that’s ABS? The highlights in the photo are a little bright, maybe your flash blew out the photo? But this is what my PLA looks like when extruded at ABS temps.

Definitely ABS. The flash did blow out the photo.