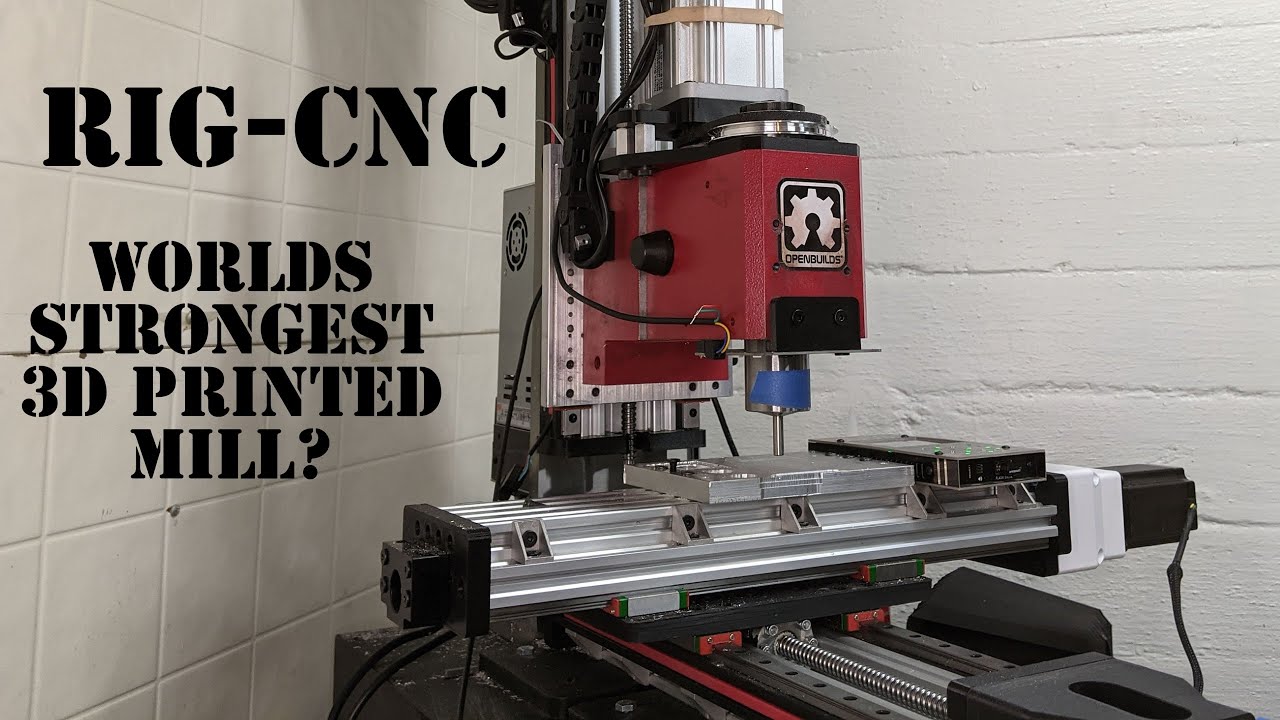

Ryan Kelly has posted a way to bootstrap a metal CNC that is quite interesting. His RIGCNC Theory of construction and Research sections are worth reading regardless of whether you build the RIGCNC (possible for $1500) or are interested in designing your own.

The magic of this design is that it can be built with minimal tools: typical hand tools, a hand-held drill, and a 3D printer. He said that his intent was to bootstrap from 3D printed plastic to metal parts, but that he is holding 5 thousandths even before replacing his two remaining 3D-printed plastic plates with aluminum. (The motor couplers I would expect can stay plastic.)

From YouTube comments:

rigidity and plastic should not stay in the same sentence

Agreed, but you’re kind of missing the whole point if that’s your take away from the video… The intent is for people to start with plastic and use the mill itself to upgrade to metal parts

…

I can get +/- 0.005 on this mill with plastic parts and that’s more than good enough for the work I expect it to handle.

h/t H-A-D