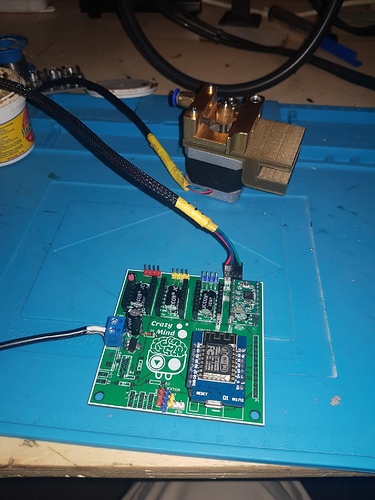

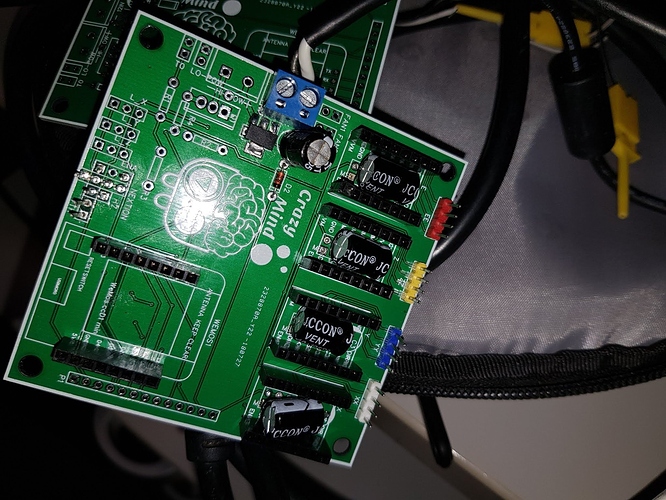

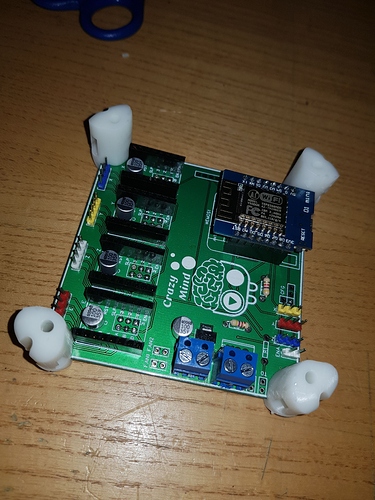

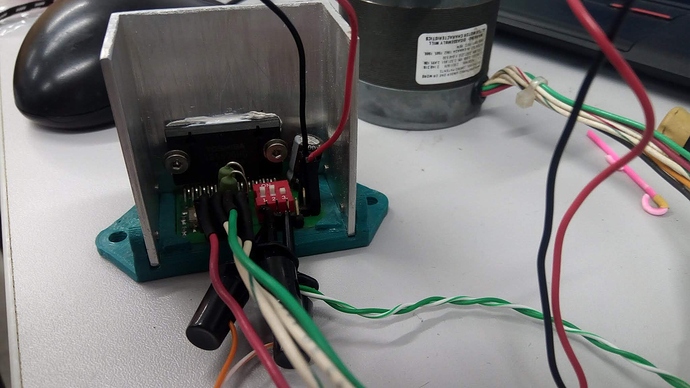

Hope soon we(me and @Darkberg_Aryavis ) can release a new ultra cheap board (for cnc printing foamcutter laser) working with D1 mini (ESP) that are a fork of kyaracontroller/repiter dedicated and cleaned for wemos D1 boards in pic we s can tested on old SUMPOD or with external driver Tb6600 l by @Maxim_Melcher PowerPony on plasma or foamcutter cutter.

Happy view.

Nice! The ESP packs a lot of power, but to control several steppers with few I/O pins you have to get creative.

https://www.youtube.com/watch?v=bhO6ckXVNgc mount pin for temperature and power output (extruder) all 4 drivers work fine… and all in wifi

Sorry, but I have to ask. Why not just a simple hat for a Raspberry Pi? Pis are cheap, run a full version of Linux, so give you lots of headroom.

@Preston_Bannister a PI gives you almost zero control over exact realtime timing.

A Pi is also expensive compared to an ESP32, doesn’t have WiFi.

Disadvantage of the ESP32, is that it has limited memory, so you need to stream your data to it.

(You need the ESP32, not the ESP8266, as the ESP32 has a dual core, allowing 1 core to run the WiFi and the other the stepper motion without interruptions)

The Fan is quite good idea to sizze it that way

My Pi3s all have WiFi. With four CPUs running at GHz rates, seems unlikely you will not haves cycles when needed. As this is a full version of Linux, we have advanced features, like processor affinity, that allow us to dedicate CPUs to specific tasks.

https://youtu.be/nG_9Fqu-0Oo currently via usb , wifi need we need a check on code/power because some time work and sometime esp going in loop of crash , via usb no issue. original code not really write fine currently want make stable board and after start coding. anyway just in usb like i like result.

@Preston_Bannister it’s not just about having cycles. It’s also about getting the cycles AKA, drivers that claim the CPU when you need it. And with the binary blobs that the Pi needs, you never really know what will happen. And cache behavior (timing changes if data is in cache or not)

You could get it right, but it’s a lot more difficult to ensure you won’t get that stutter mid job that ruins your job.

@Daid_Braam Understood. Doing real-time on a shared general purpose system is a hard problem.

Thing is, this system is used for a specific purpose, and not shared. Also this $35 board is running Linux, which is freaking advanced software. There are options, if you know to use them.

You can use processor affinity assign tasks to run on specific CPUs. So your CNC software can get a gigahertz CPU all to itself. Should be enough.

@Preston_Bannister Linux is indeed a lot of good things, but a real time OS is not one of them. processor affinity gives you a lot of power but very little on deterministic timing, unless you do very low level stuff. learnt that the hard way when working on SnabbSwitch, even on modern Xeon systems you have to disable interrupts and keep all memory allocations to the setup phase.

embedded systems like arduino, openRT, mbed, and such can guarantee microsecond latency, precisely because there’s not any other stuff around besides your application.

and honestly, when a 16Mhz, 8 bit chip like arduino can do a mostly good work with so many 3d printers, a dual core, 160Mhz, 32bit chip are much more than enough, and you can have 5 of them for less money and space than a single Raspberry 3.