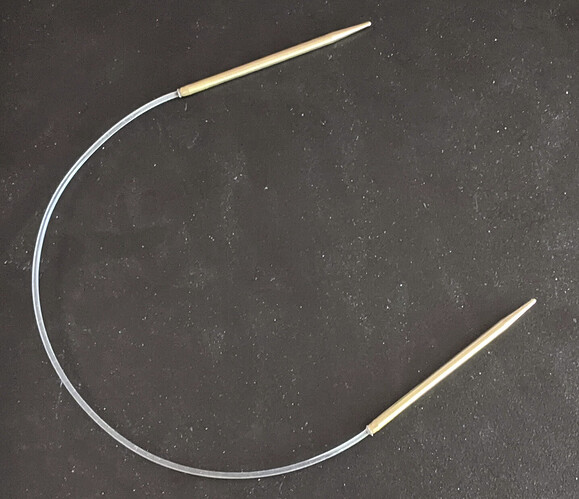

I was informed by the household knitters that there were no #4 (3.5mm) circular knitting needles in the house, yet a set was required for me to eventually wear a hand-knit wool hat. Since I have a few pieces of ¼" brass stock and some nylon filament, this sounded like a fun lathe challenge. I used a sharp brass tool with no back rake and minimal relief.

Since I succeeded, here’s my recipe.

Twice, once for each needle:

- Face off (as is tradition…), center drill #2, drill 3/32 (or smallest convenient size over 1.75mm) to about 12mm deep. (If drilling brass, remember that brass “grabs” drill bits and drill slowly.)

- With approximately 20mm of stick-out, 5° taper in .01" increments to a narrow diameter of about 2.25mm.

- With approximately 80mm of stickout, support the hole in live center, turn in .01" increments to 3.5mm diameter (or whatever diameter is appropriate for the size needles you need), about 75mm long.

- Use file or face off expanded portion from live center

- Part off at about 72mm

- Mark 70mm from end with hole

- Reverse, face off at 70mm

- With approximately 20mm of stickout, add 5° taper in 0.1 increments until undrilled end is approximately 1.5mm diameter

- Round end with fine files

Install the filament as the circ cable:

- Cut at least 26cm of 1.75mm filament. Use a tough smooth plastic. I used nylon; PETG is probably also appropriate

- For each needle, insert the filament, then hold it in a torch flame.

- Use the smallest flame you can manage.

- Put the tip of the flame 1cm from the end so that it is heating up at the base of the hole.

- Push in gently on the filament while heating. As soon as the filament starts to melt, immediately remove the needle from the flame.

- Hold the needle and filament straight while cooling.

- If a bead of melted filament forms outside the hole, trim carefully with a sharp blade, but do not nick the body of the filament

I didn’t take a lot of pictures while working on this, but here’s one in the lathe. I know that is a long unsupported span, but with a sharp brass tool, slow feed, and shallow cuts, it worked just fine.