Hi there.

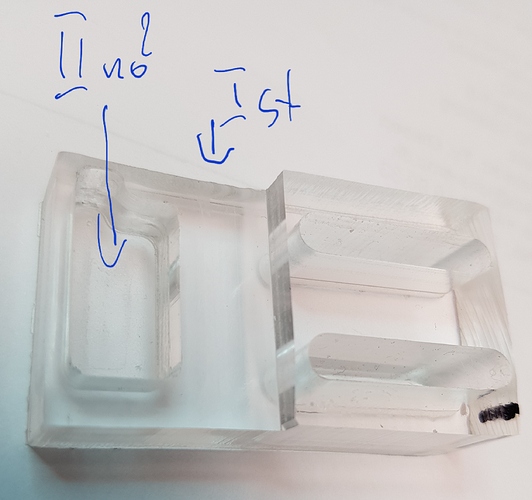

I’m having some issues with finishing pass on acrylic. I’ve prepared a toolpath using Fusion 360. Ive duplicated it and only changed the profile. Unfortunatelly it did a completely different surface finish. The first one is nice and clear without polishing. The second is milky. Is it because of the chips evacuation inside that pocket? I have a dust collector. Ive tried different feeds and router speeds until it reached the point where i needed to stop cutting. Any ideas? Thank you.

Acrylic is brutal to cut correctly. I have found that your spindle speed is a critical part of clear vs milky finish, which is basically due to heat issues. I also found that sharpness of tool is critical. Also, your chip size is critical because you’re either cutting or rubbing. If rubbing, you get milky. If cutting, you get clear. I bet your chip size is too small.

Ive tried a few different settings. I found the right cutting and router speed. My router is slightly over 2(thats around 12k) and 250mm/m cutting. I also had good results with almost 2 on the router and 200mm/m. Unfortunatelly if i change the rpms even a little bit its going to leave me with milky finish. Therefore, I find testing cuts necessary before the actual work. Some sources say you have to go for high rpms > 24k and some claim for the best finish <10k. Hm i dont know. Should I go for higher rpms or cutting feedrate?

I tend to slow down my RPMs to get bigger chips, but you really have to dial it in to a tight balance. I always had to play with it to get it right as nothing I could find in speeds/feeds calculator could quite work well for me. Don’t take too thin of a cut either. I went with 1 flute end mills for my favorite acrylic cutting so I could cut my RPM’s in half from my typical 2 flute.

It’s clear John has done more of it than me but I will agree that keeping the bit sharp and keeping the work cool are crucial.

Do you also use 1 flute for finishing passes? Lastly, what about the toolpaths? Any recommendations on settings? Climbing, 0.3mm last pass… i think Im getting there.

I have a lot of videos on YouTube where I’m cutting acrylic using chilipeppr. Maybe check those out. Yes I do finishing passes with 1 flute. I tend to do deeper cuts but using adaptive tool paths from fusion 360.

Ive watched some and still watching. Thank you very much for those.

The balance between spindle speed and chip size is essential, as well sharpness of tool, and temperature.

I try to use if possible at least a 6mm single flute double twisted spiral (usually used for playwood) about 10000 to 15000 with a feedrate of 250-450mm/min similar parameters to john expirience.

For temperature.

I could increase the quality of cutting by adding 10- 20% dishwash (You have to test different soaps) soap onto water, and sometimes even up to 50%. Using a airpressure outlet (6bar) and spray directly cooling on the tool, as well getting chips cleared asp away from cutting area.

The chips size also helps to transport the heat away from cutting area.

Hope this can help.