Hi.

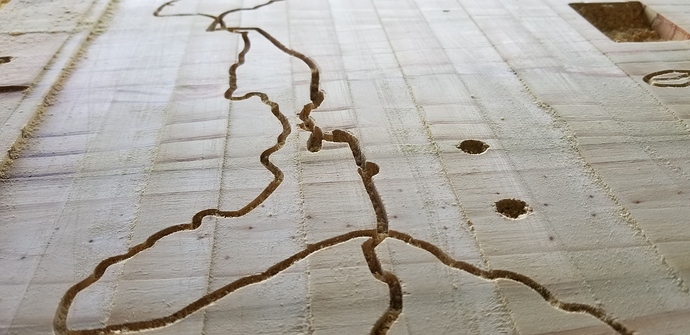

I have my ox cnc 1500×1500. I tried made spoil board and get this stepped patterns. How i can avoid this issue?

IMO your Z-axis/router is flexing on the climbing cuts. Remove all play in z-axis, slow it down or only cut in one direction.

Also make sure you spindle is trammed

@J_K11 This is a good point. I assumed that leveling spoil board was last step in fine tuning. Though the photos looks like it’s cutting deeper in one direction vs. the other. The likely is, it is not staying square during climbing cuts.

@J_K11 Nikolay, tramming is making sure that your Spindle is square/perpendicular to waste board both front to back and side to side.

Are you running a standard 60x40mm gantry? If so rotate the cuts 90degree and see if your ridges are the same (spindle out of tram) or if they change (possible torsional flex in the gantry during higher cutting forces)

Thank you all, i thought that everything good, that is why i started with spoilboard.

Another question. What is the best place where i can read about way square/perpendicular/tram my cnc. I’m absolutely new person in cnc world.