Hi guys!

Last August I started designing a F1 with the goal to compete in the regional races following the ETS rules. The inspiration was of course the OpenRC project: If you can build a truggy you can build an F1 car.

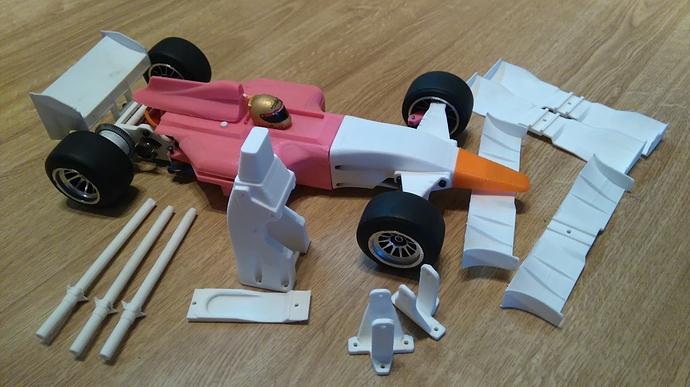

The car has a traditional pan-car layout with rigid rear axle with a ball differential suspended with a coil over oil shock absorber, side springs and damper and simple springs on the front (independent damping of front is prohibited).

Last sunday I took the latest iteration to the first outdoor competition with the goal to not come last (I have failed twice running previous versions indoors). The biggest obstacle has been the fragility of PLA in combination with the unprotected layout of a F1 car.

To this competition I took many spares, some shown on picture below, and I am now using different materials. The nose cone is printed in PolyFlex(orange) and other sensitive components are printed in PolyMax(most of the white components).

The field was thin (4 starters) but it was a representative group of drivers giving good racing. The results was very positive, it was actually the quickest car on the circuit, doing the quickest lap of the day, and I outpaced the competition in the final to actually win!

So in short: You can win with a 3D printed car!