Hey all, I want to use my 3D printer as a mill/cnc. Manly for small/soft materials. I know nothing about the software toolchain. Can someone point me at a good place to start ?

A good place to start would be to sell your printer and buy a Mill  I’ve got the Sherline mill (in addition to my 3D printer) and it works nicely on soft materials (and slowly on non-soft materials). The important point here is that the cutting tool has to be very rigid, which is not the case with a 3D printer, so the extruder mount is incapable of being a good tool mount for cutting. It does work the ‘other’ way though. you can mount an extruder on a mill and use it for FDM printing (the rigidity is over kill) but it has the problem that its slew rate (speed) can be too slow to work larger areas while keeping the material warm enough for good adhesion.

I’ve got the Sherline mill (in addition to my 3D printer) and it works nicely on soft materials (and slowly on non-soft materials). The important point here is that the cutting tool has to be very rigid, which is not the case with a 3D printer, so the extruder mount is incapable of being a good tool mount for cutting. It does work the ‘other’ way though. you can mount an extruder on a mill and use it for FDM printing (the rigidity is over kill) but it has the problem that its slew rate (speed) can be too slow to work larger areas while keeping the material warm enough for good adhesion.

Bottom line, they are in two, nearly disjoint, design spaces, with the mill being “ok” as a bad 3D printer but there is no situation where the 3D printer is even close to being an ok Mill.

I am well aware of the limitations of using a 3D printer as mill. But as a hacker/maker, I feel the need to poke and prod those limitations to see what comes out of it.

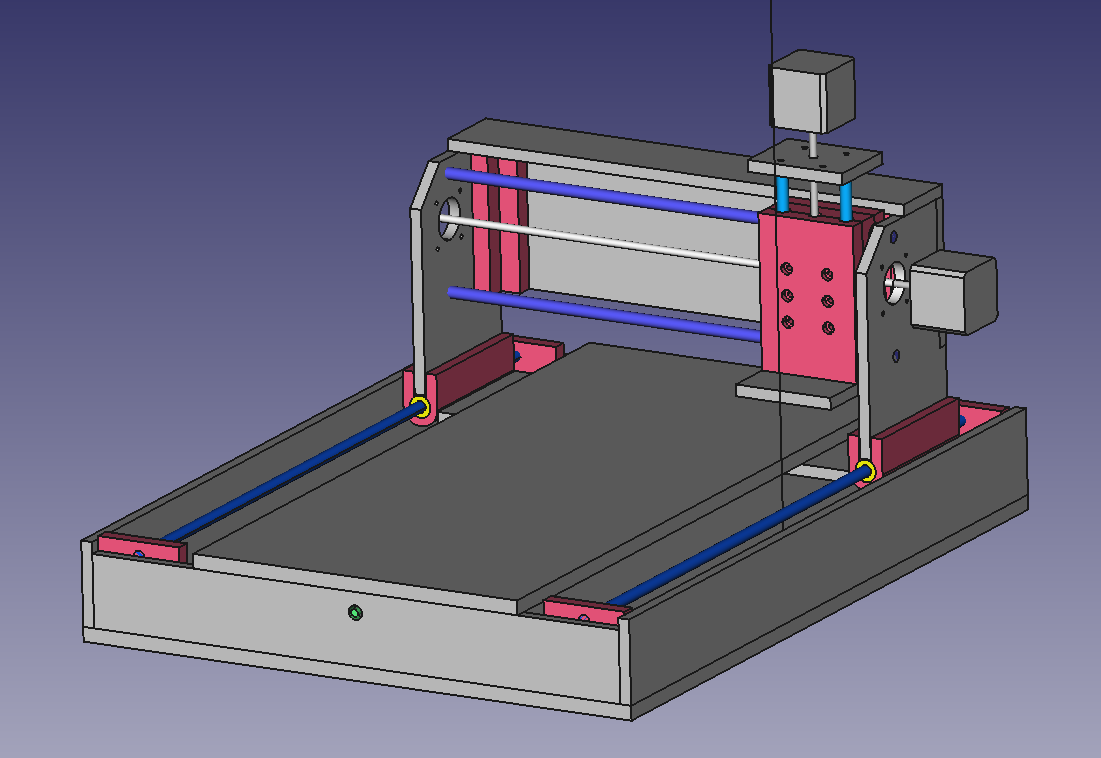

I tried it once too, but it failed to nicely drill through coper laminate. Than I thought of making CNC with help of 3D printer, it’s doable, but it occurred to me that it would be not worth it. You can see both tries here:

I’ve been a machinist for forty years. I doubt that’s gonna work at all

Depending on the parts your 3D printer is made from, the stresses of machining anything except maybe wax could also seriously degrade its accuracy as a printer.

There are enough cheapjack baby CNC designs out there that if you just want to play it would cost less to get a few more steppers and drivers, some threaded rod and a bunch of MDF.

On the software side, some searches will give you a pretty good idea of the toolchain. The design stuff is similar, the actual control side is probably going to be grbl, and the stuff in the middle to turn the model into G-code depends on what OS you’re running and whether you want to spend any money.