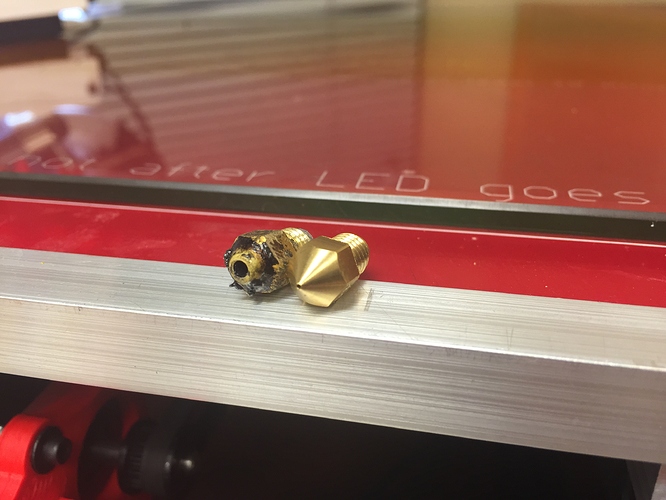

Here is what printing a 750g spool of 3dx cfrabs does to a brass nozzle.

glad am a beginner only and do ABS …

hard to hold extrusion accuracy

That genuinely started out the same diameter?

do they make stainless steel nozzles?

Yeah they’re identical nozzles… or they were anyway. Unfortunately the Pico hotend I have only has brass nozzles available.

That carbon fiber is pretty abrasive!

Well, I guess you have a fat nozzle for fast printing now.

Now you need a metal printer so you can print more nozzles

@Bradford_Short I ran about 400 grams of 3DXtech CF ABS through my E3D V6 1.75. There was significant wear but nowhere near what you experienced. http://i.imgur.com/IWJVFLM.jpg and http://i.imgur.com/R2QCjIz.jpg Maybe B3 uses a softer alloy.

Good news is @B3_Innovations_LLC already has SS nozzles in the works and should be available soon.

E3D stainless steel nozzles should work with Pico hotends. If you’re in the UK you can get them from E3D directly, if in the US Filastruder carries them.

And soon E3D will have something significantly better than both stainless and brass, which should allow for extremely long nozzle life even with the most abrasive of filaments.

Filastruder in the US had some coming. May just grab one myself

If that filament is the abrasive I’m amazed it didn’t jam a ton. Particles must’ve been really large

@Sanjay_Mortimer1 So stainless will not hold up to CF filaments over time? I did replace my v6 brass nozzle with a stainless one but have not run cf abs through it yet. If you are suggesting stainless will not be impervious to a high modulus CF filament such as 3DXtech’s, then I would rather put my project on hold until you release the new nozzle.

The top surface on Pico nozzles and E3D nozzles are not the same. E3D’s top surface is flat, the top end of a Pico nozzle has a conical taper. This is the end that mates to the heater block/barrel, not talking about the nozzle tip.

@Nathan_Walkner

Can you please give them a try first? I think they’ll significantly exceed your expectations if you give them a fair shot. Six months ago, I would have agreed with you, before handling actual parts made using CF materials, that changed my mind.

@Nathan_Walkner I don’t think anyone makes the claim that 3d printed carbon fiber is as strong as real woven carbon fiber but parts that I’ve printed are notably more rigid than regular abs which is what my parts required. PLA wouldn’t suffice due to its lower melt temp.

@Nathan_Walkner There are advantages to carbon fiber besides strength, namely stiffness which indeed is improved over unfilled polymers, even across layer boundaries.

I guess working as a materials guy in injection molding doesn’t make one an expert