Hi all, could anyone help me troubleshoot problems I’m having engraving rubber with my K40? Small items are mostly consistent, like this:

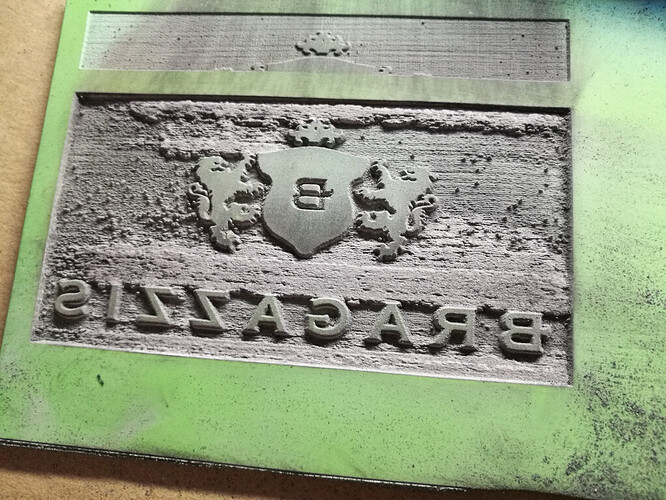

but a lot of pieces over a certain size start to go like this:

These are all 4 passes, 60mm/s at about 12% power which is definitely sufficient for smaller pieces to engrave as deep as you would want to go for a stamp. It’s eco rubber which doesn’t seem to give off much smoke or fume at all (and I’ve had the exact same issue with regular rubber so it’s not the specific material)

I clean the lens regularly with a cotton bud and it comes away with barely any dirt on it so I don’t think the lens is getting dirty - and it seems to mainly affect when the laser is making long horizontal sweeps.

Sometimes it mainly affects the areas further down the engraving, like this:

But I’ve tested a narrower piece which went almost the entire vertical distance across the bed and it was fine:

At first I thought the material wasn’t perfectly level, but I’ve tried raising it up and down by as much as 3-5mm and the effect is exactly the same.

Appreciate any thoughts!

I’ll let you know how it goes. I’ve noticed that when it fails there seems to be a lot of accumulated dust which is blacker than the material when it’s working properly, so it might be a layer of dust building up and the laser then having to fire through it…

I’ll let you know how it goes. I’ve noticed that when it fails there seems to be a lot of accumulated dust which is blacker than the material when it’s working properly, so it might be a layer of dust building up and the laser then having to fire through it…