Hello all,

I bought a K40 laser a few years ago and I never got it running like I would like since it took a lot of extra work to get it in good working order (new bed, new mirrors, air at the laser, etc). I’m hoping I can find someone in the Chicagoland area that can help get everything set up so that it is ready to cut (make any additional upgrades, change out laser, etc.). I believe I need a new laser tube as well. Mine is currently arching whenever I turn the machine on.

Thank you,

Jared

Welcome to the forum BTW.

Although we are nearly on the same latitude I am 1300 miles away so I probably can’t show up there any time soon :).

In the meantime, if you are up to it we can take on the challenge of doing this remotely.

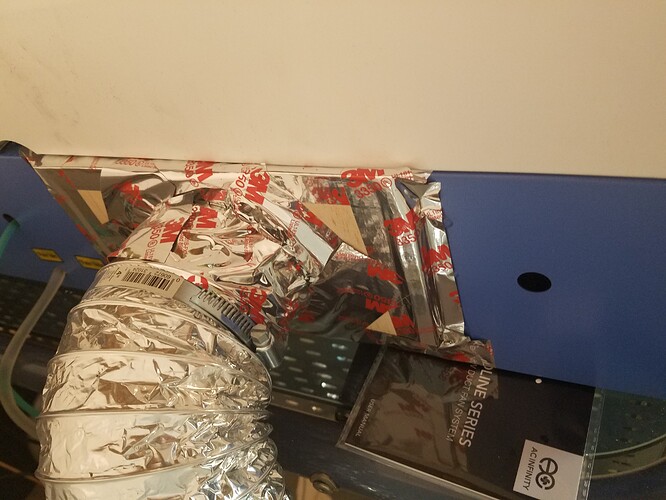

To get started take photos of all areas of the machine and post them here.

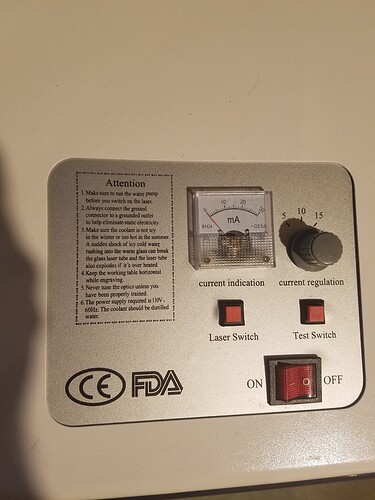

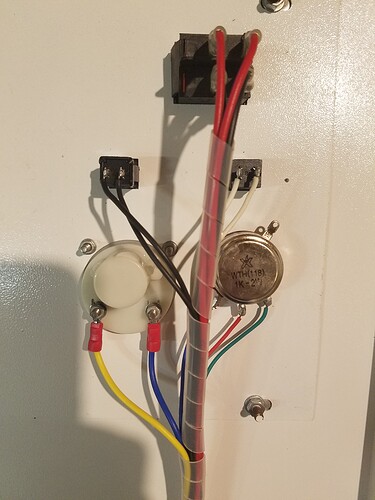

-Control panel front and back

-Electronics bay:

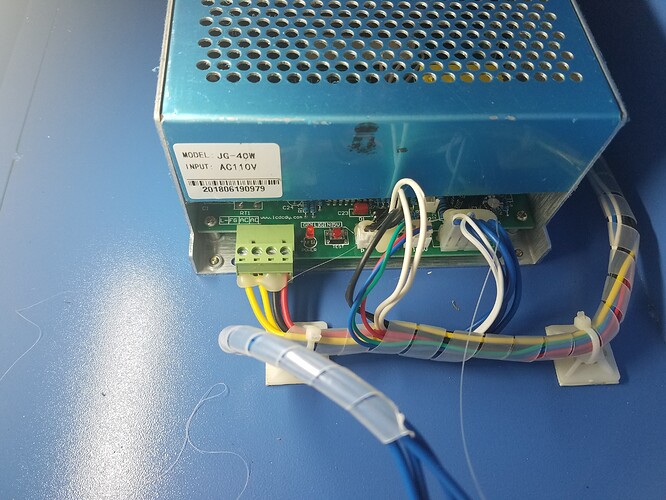

–LPS wiring

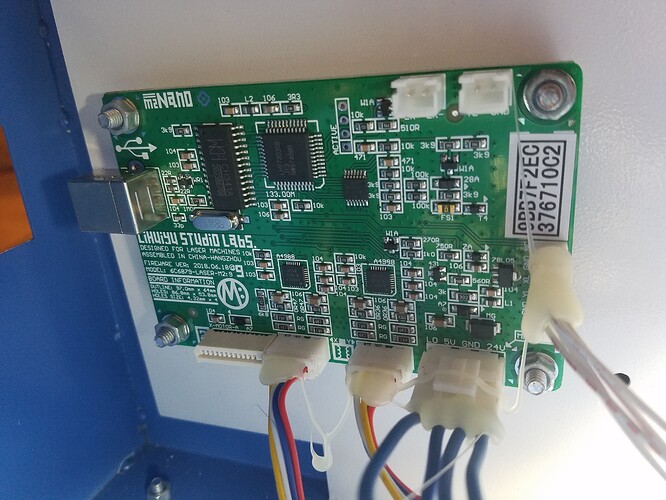

–Controller and wiring

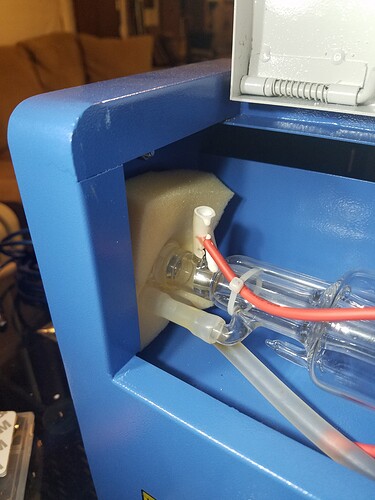

-In the Laser Tube Bay

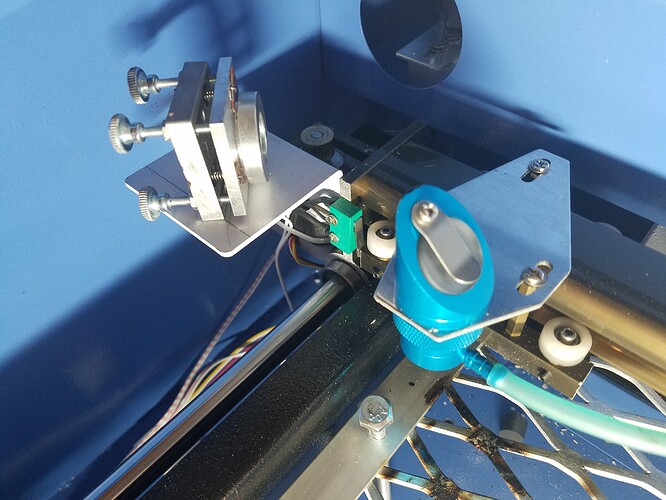

–Tube showing anode and cathode connections

-Under the cover

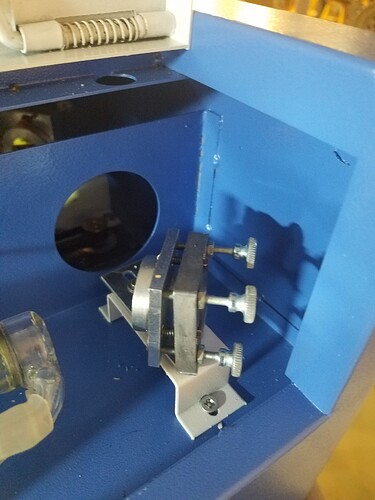

–Mirrors

–Bed

–Head

Do you mean it arcs when you turn on the power or when you fire the laser?

When I fire the laser.

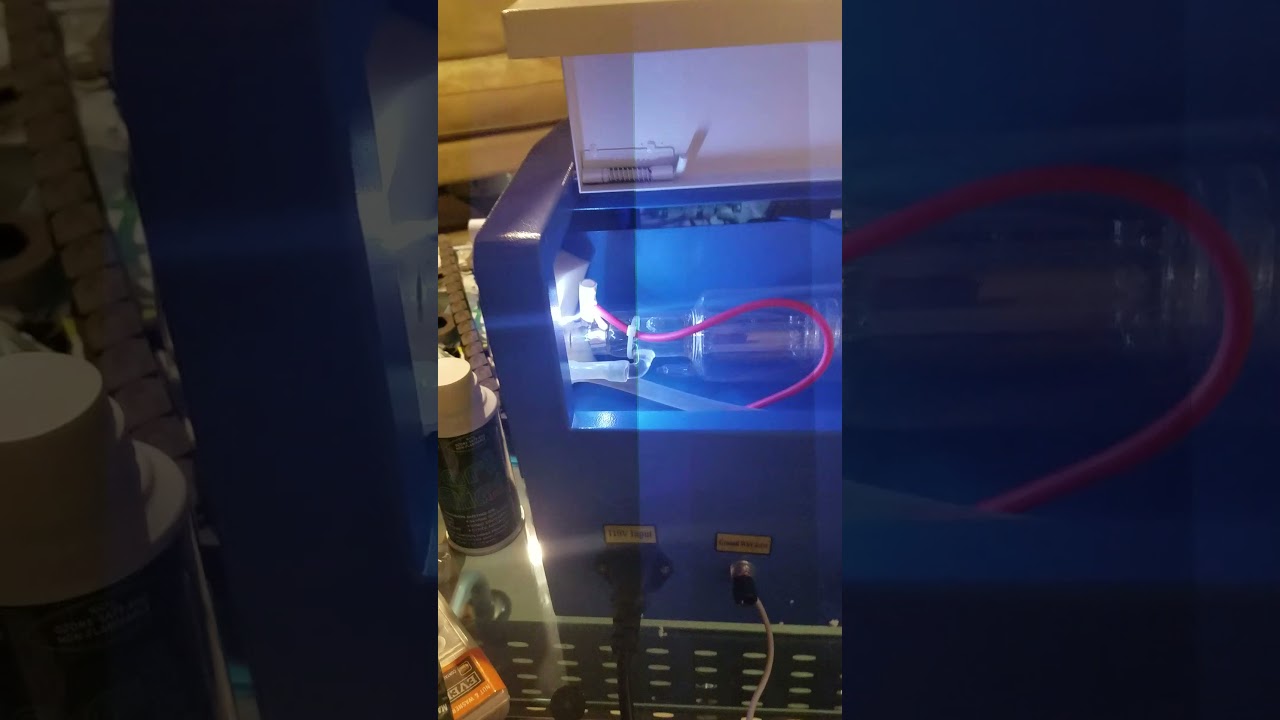

Can you post a video showing the arc?

Let me know if any other pictures will be helpful.

A picture of the front and back of the control panel would complete the set.

In the video I see the arc from the anode but no plasma at all in the tube.

It is tough to tell for sure if the tube it bad but in my experience when a tube goes bad the LPS is unloaded and it will arc like this one does.

Why is it bad:

- Its old? Tubes will eventually leak down.

- There are bubbles in the water jacket which could overheat the tube?

- The tube was run to hot?

So my guess is your tube is bad. No sense going much further until we correct that.

Thanks. I ordered a new bulb today. I will update once it arrives.

Thanks will be waiting for you to report on the new tube.

I assume you know how to replace?

Technically I don’t know how to replace it, but I have found some youtube videos that I think I can figure it out.

We have some resources linked from here:

Edit: The tube I bought is from lightobject and it already has the wires hooked up to the tube so no need to do any splicing (I feel much better about that). So I will just need to connect the wire to the power source (not sure if that is the right terminology).

I was watching a video for replacing my laser tube and the person had added quick disconnect to the HV wire. Is that recommended/OK to do? Here is the video I watched that had it. My thought would be that next time I need to change the tube this would make things much easier.

Thanks.

HV connectors are ok to use. Amazon.com

Consider:

- Even with a previously wired HV connector you may still have to reconnect the anode end on a new tube that has no pigtail.

- On a tube with a pigtail you will have to add at least 1/2 the HV connector.

- When replacing a LPS you will at least have to replace 1/2 the HV connector on the anode wire.

- HV runs with no breaks are better than ones with a connector.

Unless you are planning on taking the tube/LPS in and out a lot you may not be gaining much with a connector vs just reconnecting the existing wire back to the anode.

- Strip the HV wire back one inch

- Wrap the wire around the anode

- Replace the sleeve

- Pot with HV RTV

- Wait 24 hrs.

BTW one thing the video did no mention is to ground the anode with a wire taped on a wooden or PVC rod (chicken stick) before working on it. These HV systems can store a charge.

Three questions before I change out the laser tube.

- If there are bubbles in the water cooling tube running through the laser tube, could that be causing the arching issue?

- Just to clarify about the pigtail on the new tube I received. Are you saying to remove that wire and just run the old wire to the new tube’s anode? My thought was to run the pigtail to the LPS and connect it there. It sounds like that is the wrong thing to do.

- Is there a particular HV RTV that you would use to fill the silicone tube surrounding the Anode?

It may make sense to upgrade my LPS at the same time as I am replacing the laser tube since I plan to get an upgrade LPS anyway. Any recommendations on an LPS?

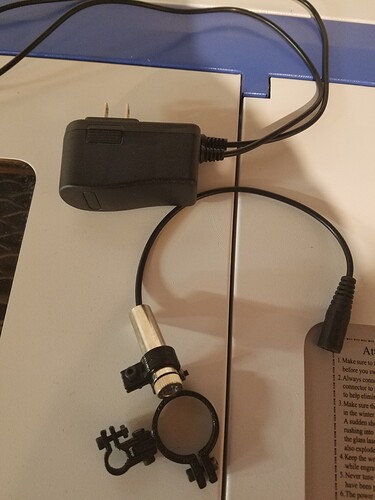

Not sure if it would help to know what upgrades I would like to make to the machine or not. I would like to use the Lightobject Z-table and a rotary machine eventually. I have also considered upgrading the controller to be able to use LightBurn instead of K40 whisperer. I would also like to add a laser pointer to the laser head so I can test cuts/identify the starting point without having the laser on. I may also want to add some additional LED lights inside the cutting area.