I will describe what I have working so you have an idea of what I have designed and the help I need.

I began this project with the goal of replacing a human operator with a robotic solution.

We were using a manually operated X-Y-Z table and positioning it with micrometers.

This was very labor intensive, and would take an entire day to setup and run a single experiment.

We would take 6 to 8 measurements, write them in a logbook and then move the table to the next position repeating the 6 to 8 measurements, and writing them in a logbook.

If we did a 30X30 Grid of measurements that would be 900 positions, 8 measurements = 7200 values.

The idea was to develop an automated way to move the sample, which I have accomplished, and to automate the data logging, which is the part I’m trying to deal with now.

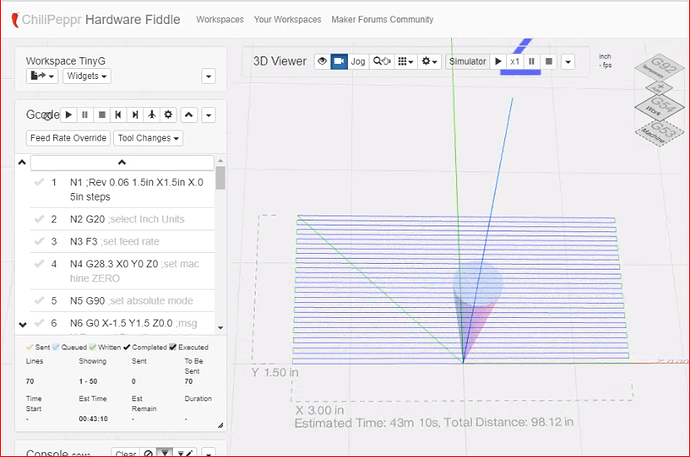

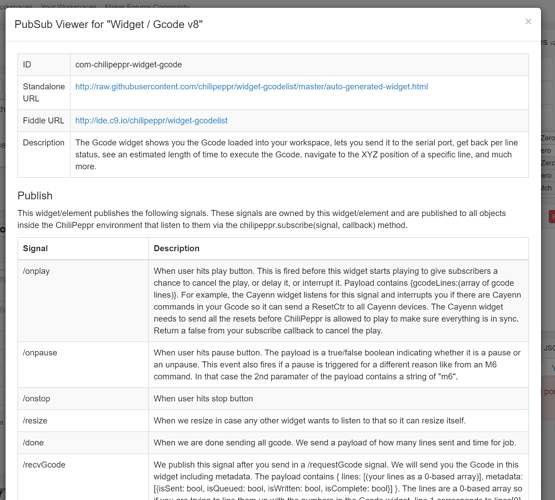

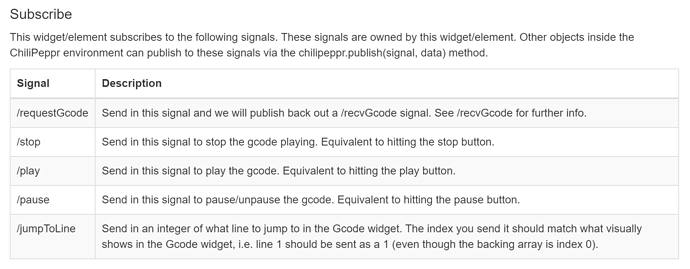

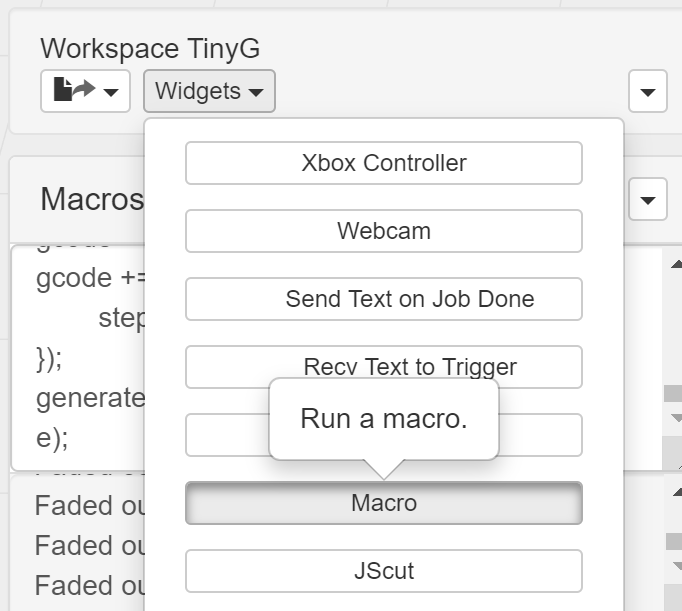

I’m using ChiliPeppr and the TingG controller with the robot. I create the G-code with a text editor.

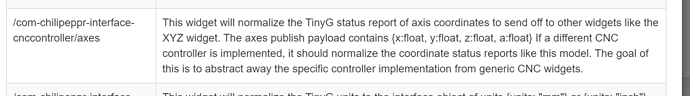

This works to move the sample, now I need to be able to record the position data (X,Y,Z) of the robot and the measurements taken at that location into a log file (CSV) to be loaded into a SQL database.

I’m not sure the best way to do this. All my measurements values are available via RS-232 or USB.

What is extremely important is that I can associate the measured values with the robots position.

I tried to do some of the tutorials but Cloud9 got in my way. I downloaded Visual Studio Code, Node.js and Brackets in an attempt to set up a development environment.

I was looking for the source code so I could look at the properties and methods availabe to me.

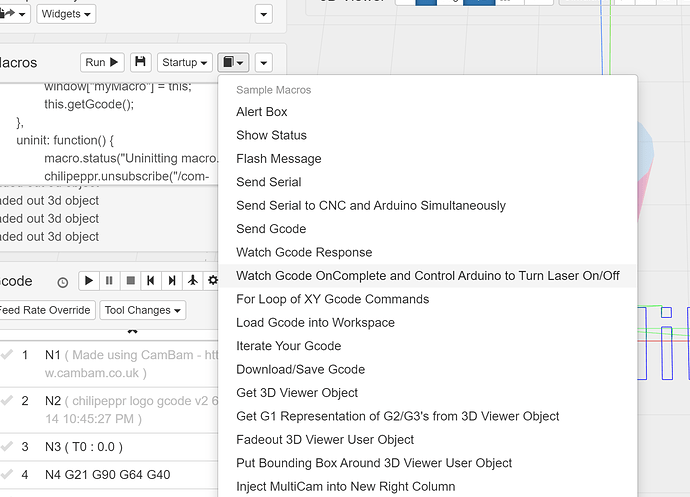

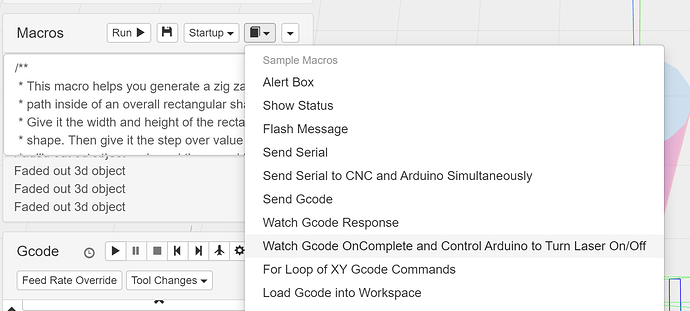

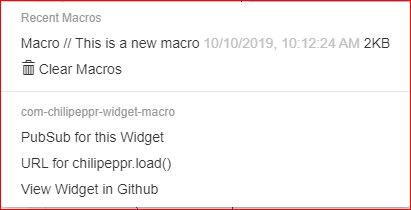

I made some modifications to one of the macros that fired a laser to have it parse the G-code.

My question is could you point me in the right direction for my next steps. I have programmed in machine language, assembler, pascal, c, c++, java and other languages but never in javascript.

I have done Client - Server and Object Oriented programming and am familiar with Networking.

Thanks