HELP ![]()

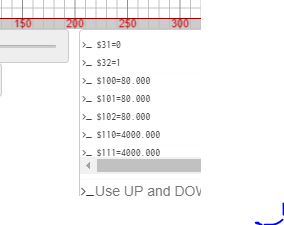

I’am lasering and during the process I realize my results are to small…

I ahve no Idea why…

elements, that are supposed to be 3 cm are only 2,5cm

and 25 cm comes out as 20 cm.

its some sort of scaling. does anyone have an idea how this can happen and how I can change this ?

{

“__version”: “4.0.991”,

“__selectedProfile”: “new-3”,

“latestRelease": “2018-06-23T08:36:10Z”,

“showMachine”: true,

“machineWidth”: 520,

“machineHeight”: 600,

“machineBeamDiameter”: 0.1,

“machineBottomLeftX”: 0,

“machineBottomLeftY”: 0,

“machineFeedRange”: {

“XY”: {“min”: 1, “max”: 50000},

“Z”: {“min”: 1, “max”: 50000},

“A”: {“min”: 1, “max”: 50000},

“S”: {“min”: 0, “max”: 30000}

},

“machineXYProbeOffset”: 0,

“machineZEnabled”: false,

“machineZMatThickness”: 0,

“machineZToolOffset”: 0,

“machineZStartHeight”: “”,

“machineZProbeOffset”: 0,

“machineAEnabled”: false,

“machineBlowerEnabled”: false,

“machineBlowerGcodeOn”: “”,

“machineBlowerGcodeOff”: “”,

“pxPerInch”: 300,

“forcePxPerInch”: false,

“dpiBitmap”: 300,

“toolGridWidth”: 520,

“toolGridHeight”: 600,

“toolGridMinorSpacing”: 10,

“toolGridMajorSpacing”: 50,

“toolSafetyLockDisabled”: false,

“toolCncMode”: false,

“toolImagePosition”: “BL”,

“toolUseNumpad”: false,

“toolDisplayCache”: false,

“toolUseGamepad”: false,

“toolCreateEmptyOps”: false,

“toolVideoDevice”: null,

“toolVideoPerspective”: {“enabled”: false},

“toolVideoLens”: {“a”: 1, “b”: 1, “F”: 1, “scale”: 1},

“toolVideoFov”: {“x”: 1, “y”: 1},

“toolVideoResolution”: “720p(HD)”,

“toolVideoOMR”: false,

“toolVideoOMROffsetX”: 0,

“toolVideoOMROffsetY”: 0,

“toolVideoOMRMarkerSize”: 20,

“toolWebcamUrl”: “”,

“toolFeedUnits”: “mm/min”,

“toolTestSValue”: 1,

“toolTestDuration”: 0,

“gcodeStart”: “G21 ; Set units to mm\r\nG90 ; Absolute positioning\r\nM4 S0 ; Enable Laser/Spindle (0 power)\r\n”,

“gcodeEnd”: “M5 ; Disable Laser/Spindle\r\n”,

“gcodeHoming”: “$H”,

“gcodeGenerator”: “default”,

“gcodeToolOn”: “M3”,

“gcodeToolOff”: “M5”,

“gcodeLaserIntensity”: “S”,

“gcodeLaserIntensitySeparateLine”: false,

“gcodeSMinValue”: 0,

“gcodeSMaxValue”: 1000,

“gcodeCheckSizePower”: 9,

“gcodeToolTestPower”: 9,

“gcodeToolTestDuration”: 0,

“gcodeConcurrency”: 2,

“gcodeCurvePrecision”: 0.1,

“comServerVersion”: “4.0.127”,

“comServerIP”: “localhost:8000”,

“comServerConnect”: false,

“comInterfaces”: [“USB”, “ESP8266”, “Telnet”],

“comPorts”: [

{

“comName”: “COM4”,

“manufacturer”: “wch.cn”,

“pnpId”: “USB\VID_1A86&PID_7523\5&4E27C13&0&4”,

“locationId”: "Port#0004.Hub#0003”,

“vendorId”: “1A86”,

“productId”: “7523”

}

],

“comAccumulatedJobTime”: 3196,

“connectVia”: “USB”,

“connectPort”: “COM4”,

“connectBaud”: “115200”,

“connectIP”: “”,

“jogStepsize”: 100,

“jogFeedXY”: 3000,

“jogFeedZ”: 3000,

“macros”: {

“*GotoXY0”: {

“label”: “Goto XY zero”,

“gcode”: “G0 X0Y0”,

“keybinding”: “ctrl+f1”,

“_locked”: false

},

“*LaserOff”: {

“label”: “LASER OFF”,

“gcode”: “M5”,

“keybinding”: “ctrl+f2”,

“_locked”: false

}

},

“uiFcDrag”: {“x”: 208.18814537070574, “y”: 800.9746693079566}

}