Hi there,

So, been working on my Eustathios, its technically a Eustathios 1 / 2 hybrid. For 5 years I have fought problem after problem until now where I have 1 problem remaining, extreme ghosting - See pics:

So it seems to be a lot worse on the X axis than the Y and for the life of me cant find the source of the problem.

I have done the following:

- So each rail moves freely without belts.

- When all the belts are on the carriage moves easily.

- Recently replaced all belts for higher quality ones.

- Adjusted the 4 corners bearing holder placements repeatedly

- Run burn in code for 3 days

- Tightened belts

- Loosened belts

- Raised acceleration

- Reduced acceleration

Can anyone suggest anything? I plan to sand down my stainless steel rods in a few days as a last resort, but wanted to see if I’m missing anything. I am currently using self aligning bronze bushings.

1 Like

Two things you could try that maybe would help. First thing is swap the X and Y motors with a powered off course. And see if you can get it to follow the motor or driver. Second thing would be lower the acceleration to something ridiculously low like 300 or 500 and see if it goes away. I haven’t run into those sort of problems myself in a long time and most of it was tied to alignment and bushing stick/slip especially when the bushings were brand new and tight. I know one person back in the Google+ days had a pulley that was slightly eccentric which was causing an issue. I think he switched to proper misumi pulleys instead of the cheap Chinese ones on the sides which helped.

1 Like

Hi Eric,

Thanks for replying! I hadn’t considered the pulleys being at fault, that’s certainly a possibility. The bushings are quite old and i would have though worn in by now. I should note I haven’t had this ghosting issue the entire time, only recently since resolving my bed levelling issues. I will give what you suggested a go though.

Thanks for the help.

I’m sure you’ve played with them, but what speeds are you running?

Sorry for the slow reply, passing my masters took priority! Now that’s done back to solving this.

@Ether_Bunny I’ve tried all different speeds, since last posting I have tried lowering the speeds along with higher and lower acceleration settings but the results are very much the same. If anything any deviation away from my current settings increase the problem which suggests it’s a hardware issue.

@Eclsnowman How tight are the belts supposed to be? I have read both super tight and not so tight so not entirely which one to go for. I will look at swapping the motors in the next day or so.

Belt tension can be kind of a contentious issue depending upon who you ask. Personally I run my belts tight but not super tight (not like a high e string

One problem with a gantry style setup is if you set the belts too tight you can actually start racking the frame. I think even more important than a specific belt tension is equal tension between two opposing sides.

Another thing I found in recent years is that a lot of people run their acceleration far higher than is realistically required. To be honest as low as 800 is really fine for 95% of all printing. that being said I probably run mine somewhere around 1500 nowadays. One thing I recommend is making a tall print that specifically tries to introduce ringing, and then use g codes throughout the print to change parameters that you think might be affecting it and see whether or not it changes as you go up the part.

Have you tried playing around with S-curve acceleration. I can’t remember if you said what controller/firmware you’re running. Several years ago I switched from Smoothieware to Marlin. setup can be more daunting on Marlin but I found I like some of the newer features available in the Marlin firmware.

Another thing I’ve seen before is that the whole framework assembly is good, but that the hotend is loose in the carriage. With the hotend cooled off, grab it at the heater block and try and wiggle it. Does it move in relation to the carriage?

So I just checked the hot end and that is nice and tight, any movement is seen in both the hot end and the carriage.

I should have mentioned I am using a Duet 2 Wifi so reprapfirmware 3, literally just replaced it as well as my old one burnt out (gutted that wasn’t the cause of my issues  ).

).

Looking at your accelerations maybe mine was a bit to high, I originally used Oliver Seiler’s config on the Eustathios spider git hub but it would seem I had increased the settings over time, so I have reset these back to this Oliver’s config and i will try a test print again. I don’t recall Marlin being compatible with the Duet but I will have a look in to it. I am familiar with both firmwares as I have an Ender 3 and other printers running Marlin. Is there an equivalent to the S-Curve acceleration in Reprap firmware?

I think maybe I need to re-do my belt tensioning again. I went as tight as to break a couple of the bearing holders in the past so I’m guessing that’s way to tight. I will also try the changing settings on a fly as well to see how that effects the print.

Thanks for the help!

RRF3 is very good. I don’t think we need to change that. But I would set up that test print and just change the acceleration with gcode commands as you go up the part. It’s a pretty easy way to see if you’re facing up the wrong tree.

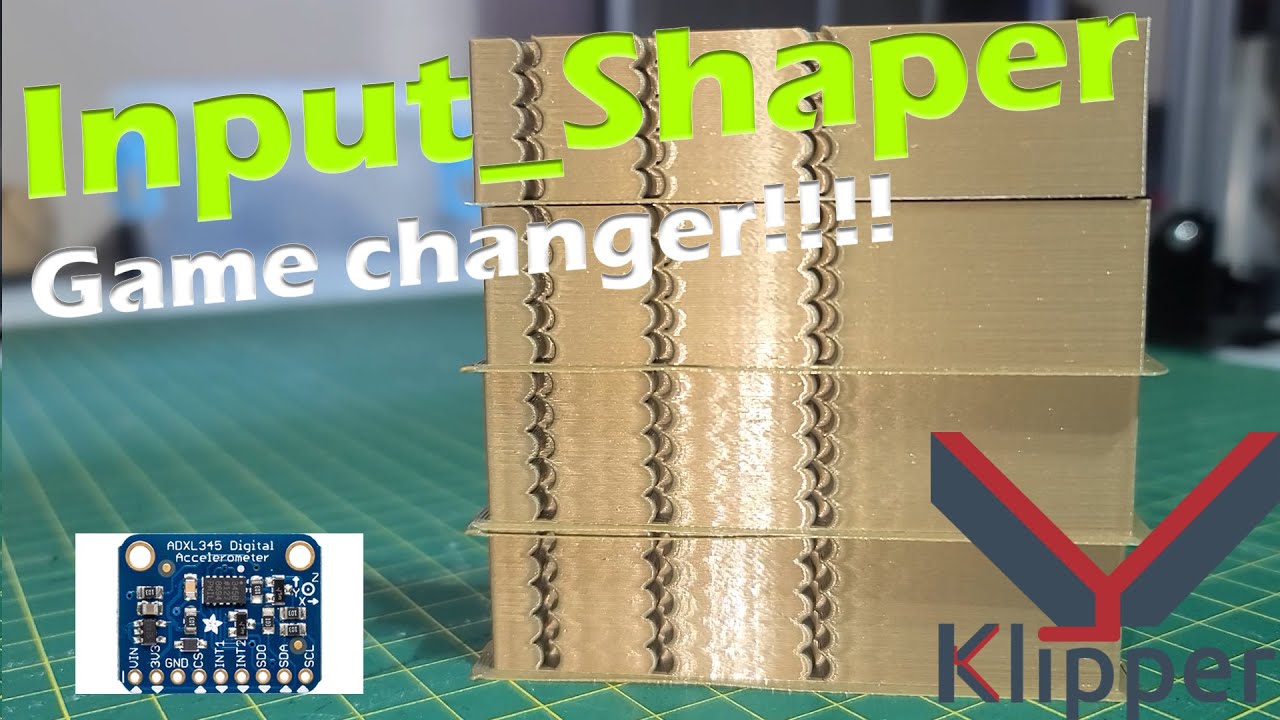

This is a longer video to watch. And not directly related to what you’re dealing with due to your firmware etc. But a lot of good information in here, especially as you get towards the end of the video and he’s talking about belt tension. I’ve never used Klipper before, but it seems like there’s a lot of really innovative advancements being made on the software side in that space.

1 Like

).

).