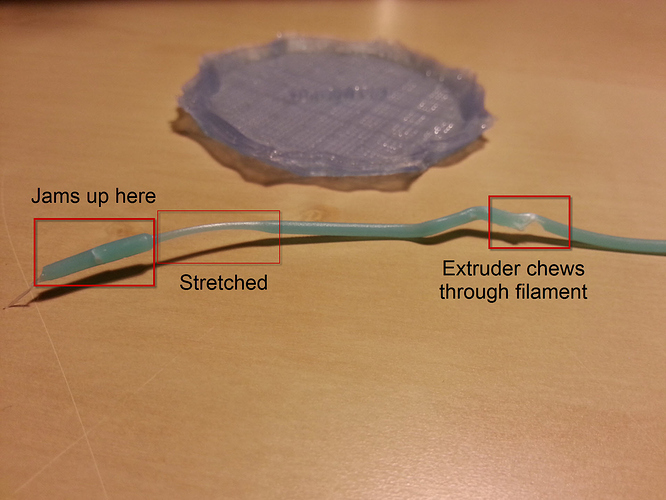

Having issues with my filament getting jammed. I don’t think it’s from dust particles or dirt, it seems to only happen when I’m at a part of a model that is using quite a lot of retraction. Any thoughts on the cause?

ABS or PLA ? What printer / extruder are you using ?

PLA, 1.75mm. Printrbot Jr. wooden extruder. Using the Ubis hotend with a 0.4mm tip.

I’m no expert, but what does the hot end look like? Is the upper part being cooled with a fan? What’s your retraction setting?

The upper part is indeed cooled with a 40mm fan running at 80%. Retraction length is 2mm, Lift Z: .25mm, Speed: 10mm/s

It looks like there’s still too much heat creeping up the hotend.

10mm/s is way too slow - increase that to at least 50 and the fresh filament will help cool the top of the hotend.

@Thomas_Sanladerer , that speed is the speed of retraction, not the speed of printing. Although, I really should increase that. I’ve been printing more slowly lately to try to solve some cooling issues.

Well Ok, that makes sense. I take it you also have a fan blowing over the printed part to help with cooling?

Yep.

Where are you getting your filament from? Is this filament from a different supplier? Did it just start?

How does the extruder motor sound? Is it possible you’re losing steps in the retraction/reset sequence? Is the motor hot? Is that the retract speed you listed? I believe I solved a similar problem on my PB+ by adjusting the amperage setting with the pots on the printrboard, reducing retract to 0.5 mm and slowing retract speed to less than 10 mm/sec, IIRC. I figured I just need to retract enough to kill the stringing, and not so much that I’m drawing air into the hotend.

@Aaron_Eiche , I’ve been having this issue across different filament from different suppliers.

@Robert_Swarner Extruder motor sounds normal (musical) to me, though it seems to be running rather warm (but not hot) to the touch. I’ll try reducing retraction to 0.5mm. Not sure about those pots on the printrtboard, I’m not sure what they’re supposed to be set at. I have a multimeter on the way from Amazon, so I’ll be able to check to see what they’re outputting.

Try lowering the retraction and see if it helps. When you repeatedly extrude less between retractions than the length of your retraction, you compromise the structural integrity of the filament and your ability to grip it. This is particularly true of fixed-distance (springless) and non-bearing idlers, and some filaments (material, supplier, color, etc.) are more susceptible than others.

I’ve always found that lots of retracts close together just serves to grind a notch into the filament. Can you set the min travel distance to retract to about 20mm or more?

That will inevitably cause stringing on detailed parts - i have my min travel set to 3mm. If you want to go higher, you need quite a fast bot, which the printrbot is not.

Have a look here for the trim pot setting for current control. Since you have a Jr, it may be that yours are already set at “4 o-clock”, but it’s worth a look.

http://www.printrbottalk.com/wiki/index.php?title=Getting_Started_Guide

Also, I have had many issues with temperature at both the extruder and bed. My extruder thermistor indicates high (hot end is cooler than reported), with the opposite problem at the bed. Is it possible you’re running the hot end hotter than necessary? Try manually bringing it down until it begins to have trouble extruding (then back up) to get an idea.

@Robert_Swarner or anyone else that knows, is there a way to measure the current output to determine if it’s putting out what it should be? How do I know what the board should be outputting? Pretty new to this electrical stuff

It’s not easy to do directly. That’s why they recommend an o-clock position on the trim pot. There is a sweet spot where there is enough current to make the motor move every time you ask it to, and not so much that it resonates and bounces between steps when it gets there. You’ll find the “musicality” changes with the current, since what you’re hearing is resonance of the motor. So I would look to see where they are, and if they are at 6 o-clock, I would experiment with little moves that you can undo. 4 o-clock sets the amperage lower than 6 o-clock.

Having said all that, I would try the other stuff first.

Measuring the voltage at the pot’s wiper allows you to precisely calculate the motor current. Pololu’s drivers even have an exposed test point for this.

@John_Schneider This was really frustrating me even after putting in a nylon insert to support the filament inside the extruder (as we had discussed before). Come to find out the extruder is capable of some serious pressure against the filament that causes the filament to flatten out and jam inside the ptfe liner of the hotend. After taking the extruder and hotend apart the last time, I played with running the filament through the extruder body without the hotend attached when I found how flat the filament was. After backing off the idler pressure quite a bit, I got it to where the filament was still round but still had teeth imprints visible. Since making that little change and putting it back together, its been going non-stop.