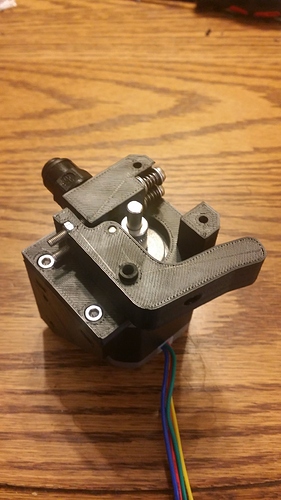

Has anyone else had any problems with using an MK8 hobbed gear with 1.75 filament. I have redesigned my direct drive extruder 3 times now thinking it was the design and maybe not enough pressure pushing against the extruder but now I’m thinking that it might be the hobbed gear. In looking at the depth of the teeth and seperation of the teeth on the MK8 compared to my homemade hobbed bolt on my wades geared extruder…which works fine and only strips filament if the nozzle is pressed against the bed…the MK8 has a deeper cut and the teeth seam to be seperated more than my hobbed bolt. The only other thing that is different is on my new direct drive, I’m using a small bearing…8mm OD compared to my Wades geared extruder which uses a 22mm OD bearing. Any input would be greatly appreciated.

What program did you use to design that? Im working on a extruder too, and sketchup bugs out a ton and does things which its not supposed to do

Maybe, with a bigger bearing, there is a larger amount of surface area on the filament? With a smaller one, there is less surface area pushing on the filament and thus maybe causing it to slip.

@Matthew_Moore I was just comparing the 2 bearings and was thinking the same thing. And I use SolidWorks for all of my modeling

@Mike_Smith I’ll have to look into solid works. Is it the best for general 3d modeling in your opinion?

@Matthew_Moore SolidWorks is what I’ve been using for my job for the last 12 years so it’s what I’m comfortable with. It is great for mechanical models and is probably one of the most commonly used programs for such. Once you learn the layout and order in which to do things you’ll find that there is pretty much nothing that SW can’t do.

@Shauki Thats very similar to the design I’m working on now but the small diameter bearings seam to be striping out the filament. I made a makeshift test extruder with the larger bearing and it works a lot better, so I’ll be redesigning my extruder to use a larger bearing and then so how it holds up.