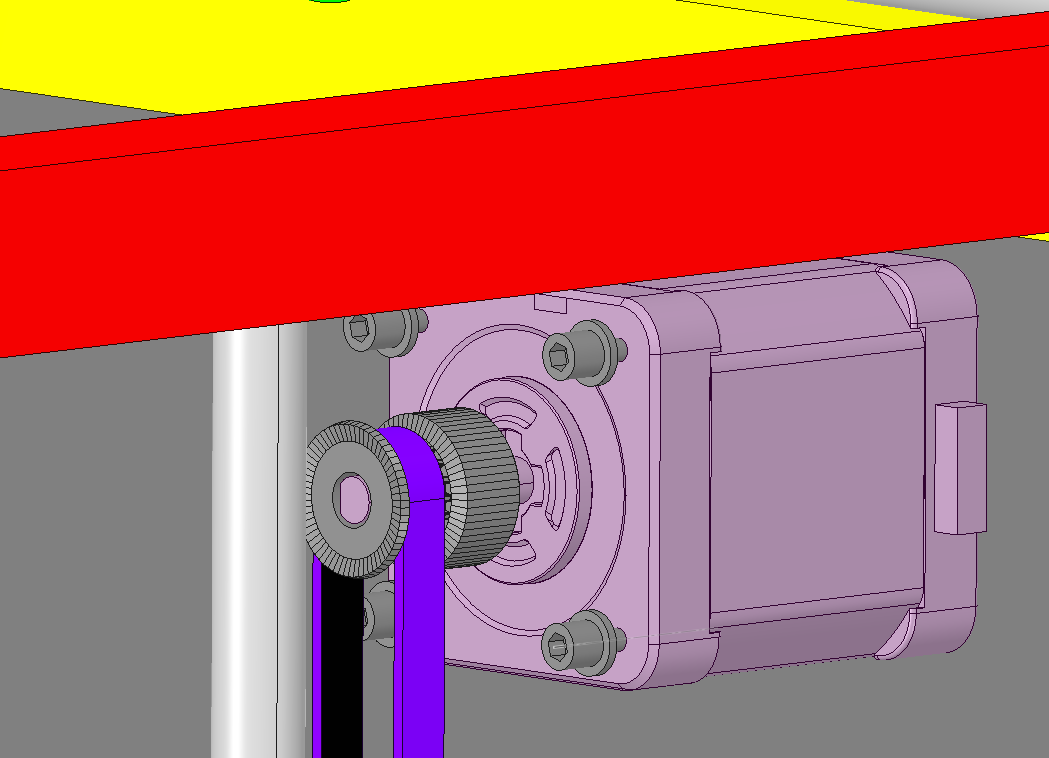

Guys, how would you mount a stepper motor under and along a square tube like shown in the pic below? I am not very confident in my current design as it is (http://www.thingiverse.com/thing:1487375).

Please don’t suggest extrusion (I have that in works), I am interested in doing this variation with square tubing.

@Rien: That might actually work. I knew about these but I just now realize that the slots are 31mm apart while the square tubing is 20mm apart so I might get some bolts up in the slots and fasten with another plate on top of the tube…

@Rob_Palmer

I would rather go around the tubing and avoid too many holes.

Plenty of hot glue and then more hot glue piled on that, that’s how I’d build it.

I just don’t trust that much my design for the Z motor mount… it will rock around the plane where the screws go through the plastic into the motor as the motor changes rotation direction. Granted, it shouldn’t happen with a level bed where auto-level compensation is not employed and the load would basically be in one direction only as the bed descends layer by layer…

I would use a formed sheet metal piece. Its the only way to securely place and secure a motor like this. We normally do a custom one however I have idea if you can get an off the shelf piece.

@Rob_Palmer

I asked how would you do it to pick your brains regardless of my wishes. I need a simple way (plastic or metal) that would securely mount the motor to the above square tubing without being too flimsy during normal operation.

I have also specified one constrain and that is that I would like not to put holes through the tube but to use some sort of clamping for the job.

@Ross_Bagley

Forgot to answer this:

3DHubs seem very expensive in this area and I didn’t consider this when started designing the #SCOUTcorexy; I had access to 3d printers at the time. Now I see the need to be able to build the first printer with (if possible) zero printed parts, a simple enough printer to use and print the parts needed for a bigger, more complex printer.

I am trying to replace some printed parts with something I can easily adapt so I can later on print them like I intended.

@Rob_Palmer

I don’t get it, after your first answer I said I want to go around the tube (clamp?) as I don’t want to put holes through the alu square.

And I appreciate all the answers, I don’t necessarily want the answers I am also able to imagine, but something that I might not think of or not know about.

@Ciprian_Balalau_Make BTW, your (all?) metal cantilevered design looks better and better for a printer to start with, apart from having a friend do the printing for you

I just moved here, haven’t got the chance to meet any yet but there is no maker space or any apparently visible organized movement in the city. Yeah you could tell I want to repstrap but basically @Rien_Stouten 's suggestion is a good one and that’s a normal Nema17 mount, no rep-strap there. I have though the possibility to get one fabricated. It’s funny that 3d printed parts are expensive while I can have some friend of friend make one from sheet metal basically for free.

BTW my design is no repstrap at all but I didn’t envision issues that one might get into when not having another 3d printer to start with.

@David_Clunie

A flared out U-bracket would work, something along these lines: http://cdn1.bigcommerce.com/n-ww20x/2454y/product_images/uploaded_images/joist-hanger-4.jpg. I’d have one on each end of the Nema17.

I’ve tried some quick sketching so maybe something like this?: https://is.gd/zk6q92