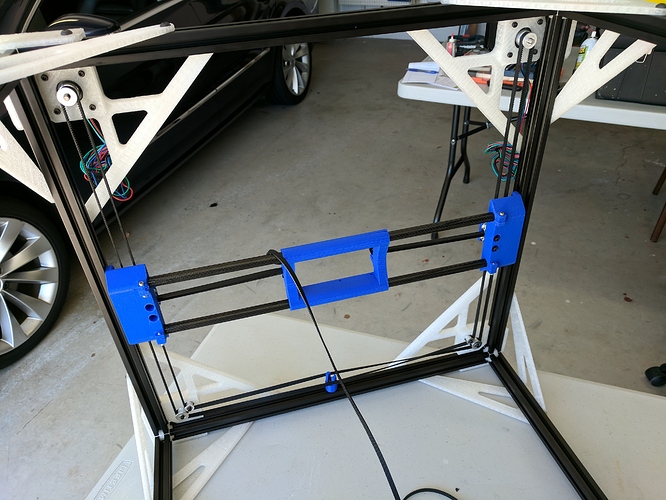

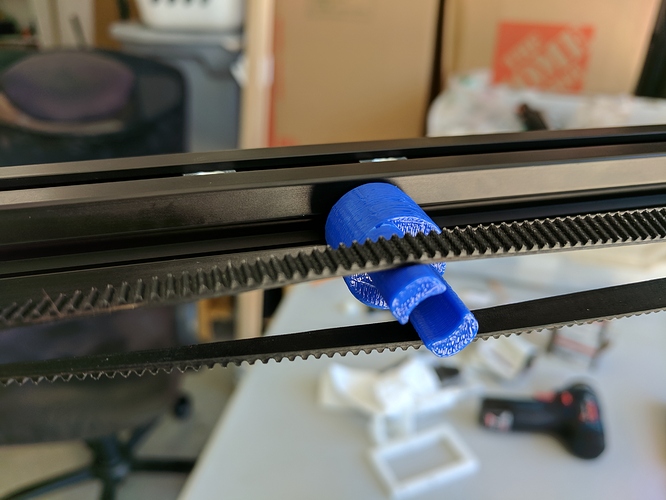

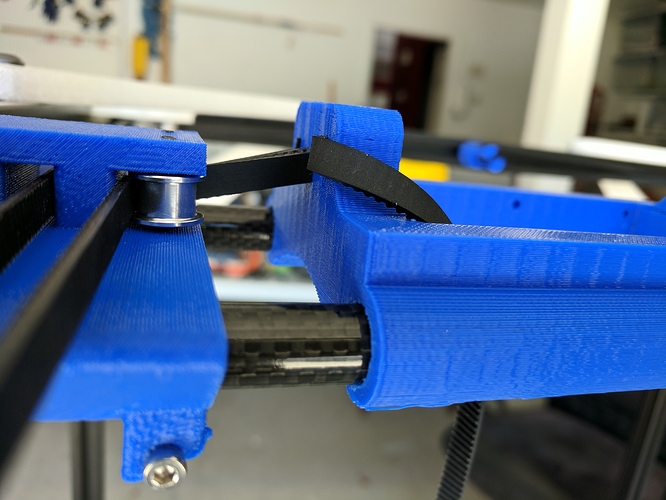

Got a complete iteration of the XY gantry printed, and the belts run (for the first time!). It is functional - in that everything moves correctly, but only that. Keep in mind the prints are all PLA, which for sliding bearings is not a stellar material. The purpose of this iteration was to verify fit. I can add better bearings a bit later.

As to fit, my “boat” for the print head rose a few millimeters between iterations. Right. Printing a corrected boat…

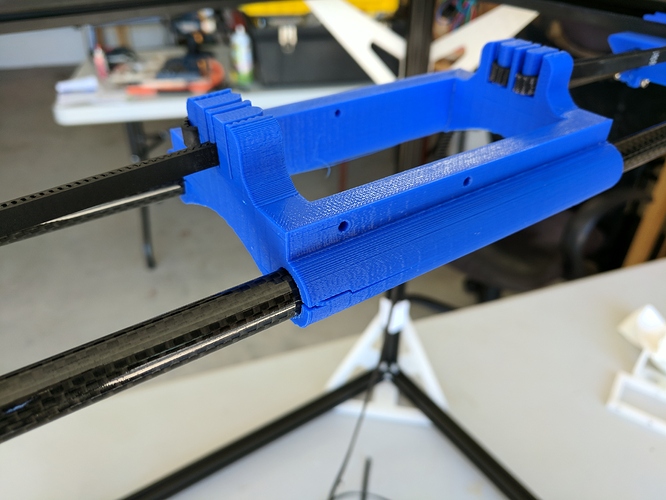

Not fond of Hatchbox PLA (the parts in blue). Had to slow the printer way down to get passable prints, and … they still have issues.

That said, the friction moving the gantry in Y is … not too bad. With PLA the sliding and static friction are a touch high, but might be tolerable. With better bearing material, the Y sliders might be entirely acceptable.

The friction in X movement is very high. In part as there is simply too much bearing surface, and in main was the print is a bit crude around the through-holes for the rods. (Do not have anything to bore out a 12mm hole.)

Removed the excess material, and re-oriented the print in hope of better precision and strength. Will see, in about eight hours.

Still, kind of jazzed to be able to string the belts for the first time.