You asked in another post about my approach to dust control.

https://plus.google.com/+DonKleinschnitz/posts/KbsiCEX8RoH?fscid=z12ujx4btlqlyvanj232ddzwfne0cn0tv.1516507711110605

…

Goals

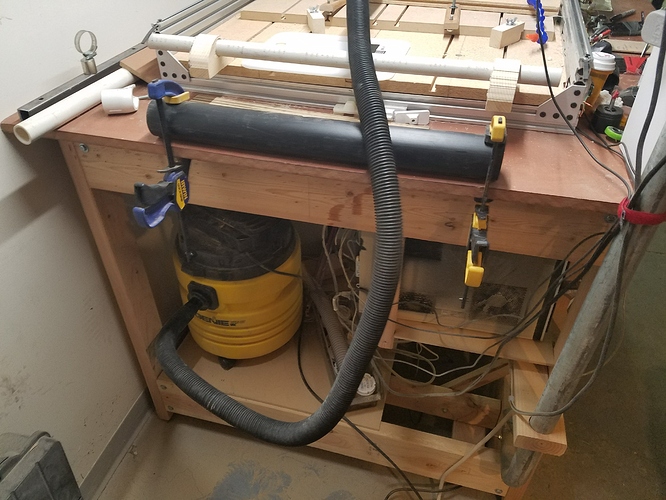

Attached are some pictures of my prototype.

I want a design that has:

- good visibility of the cutting area and bit

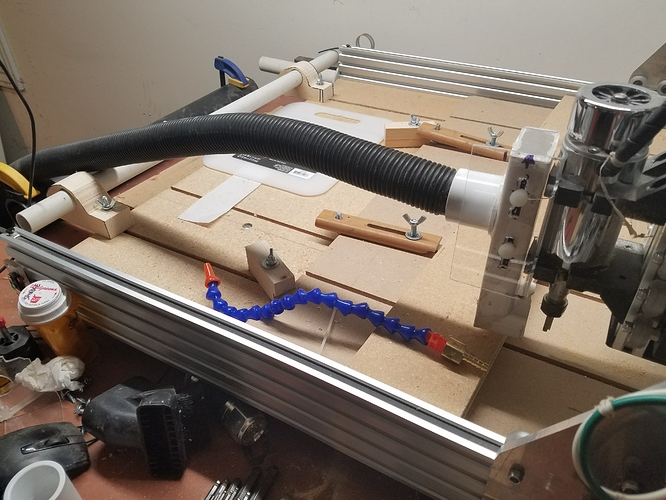

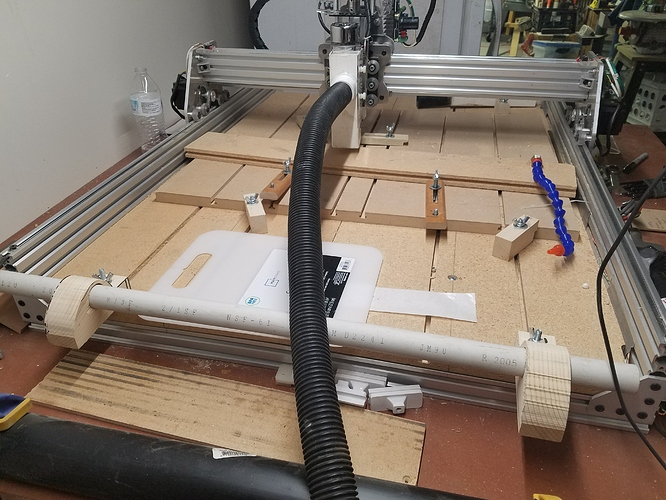

- vacuum and hose is self contained with my table because it is mobile.

- minimal force and weight from the shoe and hose management on the gantry

- minimal fabrication and cost.

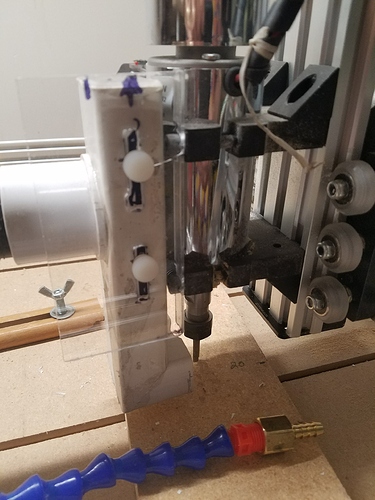

I have started using a minimalist concept of another community member that used a cut off piece of PVC fitting that hugged the spindle. https://openbuilds.com/threads/cheep-and-dirty-dust-collector.7770/

Concept

The concept is to have an open vacuum shoot near the cutting area with a lot of vacuum and an air assist to blow the material out of the cut toward the vacuum chute.

Thinking about using the output of the vac as the source for the air, other wise use a separate pump. The air assist is not mounted in these pictures but I plan to mount it using the plenum mount.

If this does not give me the extraction I want I plan to put a acrylic shoe under this plenum and if needed add a clear flexible material for the brush.

This vacuum plenum is easily removable and vertically adjustable and very lite.

Fabrication

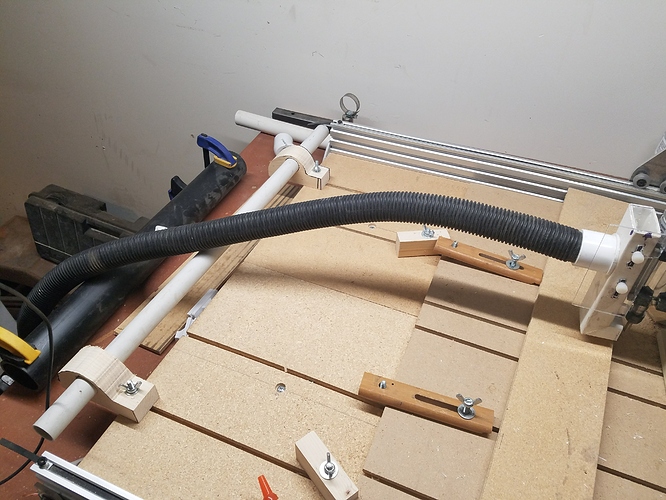

The vacuum plenum is made from the rectangular slats from a pvc fence I tore down. Like this:

https://www.lowes.com/pd/Freedom-Actual-3-83-ft-x-5-64-ft-Ready-to-Assemble-Durham-White-Vinyl-Panel/50179759

Everything uses “Plumbers Goup” for assy. until the proto is tested.

The hose fitting is a reducing coupling with the inside turned on the lathe to friction fit the hose. Its mounted over a hole in the plenum.

The top of the plenum is closed with a a piece of acrylic. Brass heat inserts provide a fastening means.

The plenum is mounted to the gantry using a piece of acrylic fastened under the spindle brackets. The mount has slotted holes so the plenum can be moved up and down.

The vacuum hose hangs down over the table. It runs over a movable horizontal roller [although I have found that it doesn’t need to rotate] and a fixed roller at the edge of the table. The vacuum is under the end of the table. So far it moves pretty easy. Will have to find out if for larger materials its in the way.

Still a minimalist idea in process! Like most designs reality will probably show up and make it more complex :)!