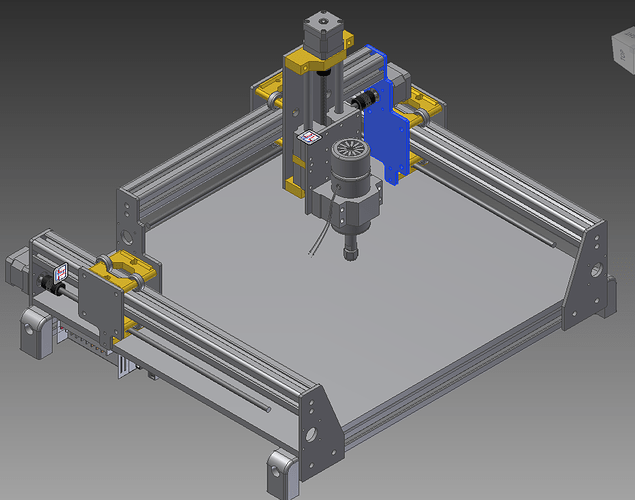

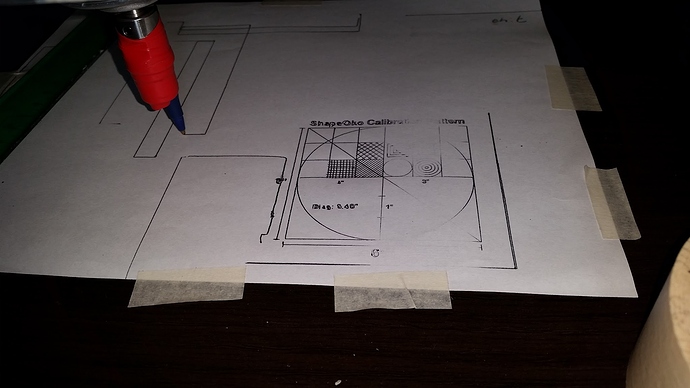

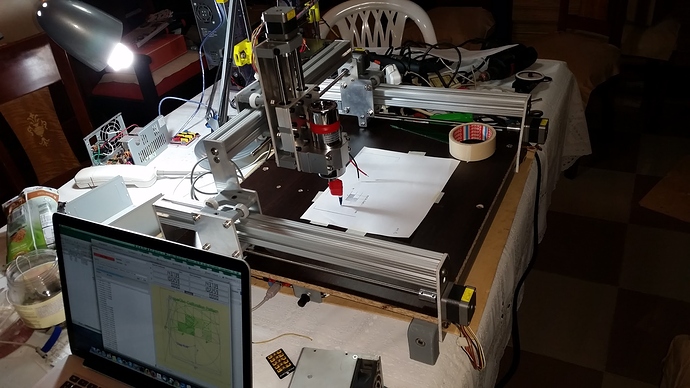

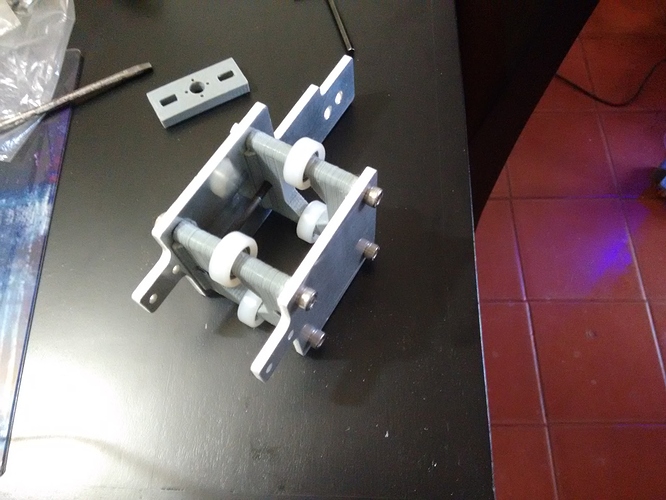

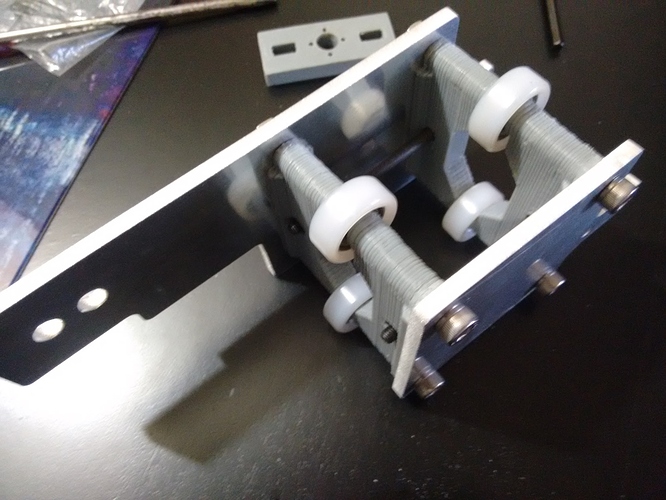

From CAD Design to reality. Bed need to be changed for a smooth and level surface. 3D printed parts for X axis, need to be reinforced. Uses Arduino Uno and protoneer 3.0 board. Screws of Y Axis need more pitch for faster movements. Need Stepper motors with more torque for aluminum milling.

Nice! Pregunta: los rodamientos que corren sobre el aluminio extruido fueron hechos a la medida? O existen comercialmente para correr sobre la hendidura del aluminio?

The easiest way to get a flat bed is to use a wide levelling bit on the router - like this one: http://www.aliexpress.com/item/1PC-X-High-Quality-shaped-CNC-Router-Bottom-Cleaning-Router-Woodworking-Bits-SHK-1-2-12/2023624577.html

It also allows regular cleaning of your sacrificial bed back to a level plane.

Buen trabajo @Patrick_Becker ! Oye podrias pasarnos el link o como encontrar los recubrimientos para el rodamiento que utilizas?

Saludos