For some time, I have a eShapeoko with TinyG v8 and Chilipeppr running nicely. Since I have some plans for both a new CNC and SMD pick-and-place machine I started investigating the use of G2 for it (which is great software!).

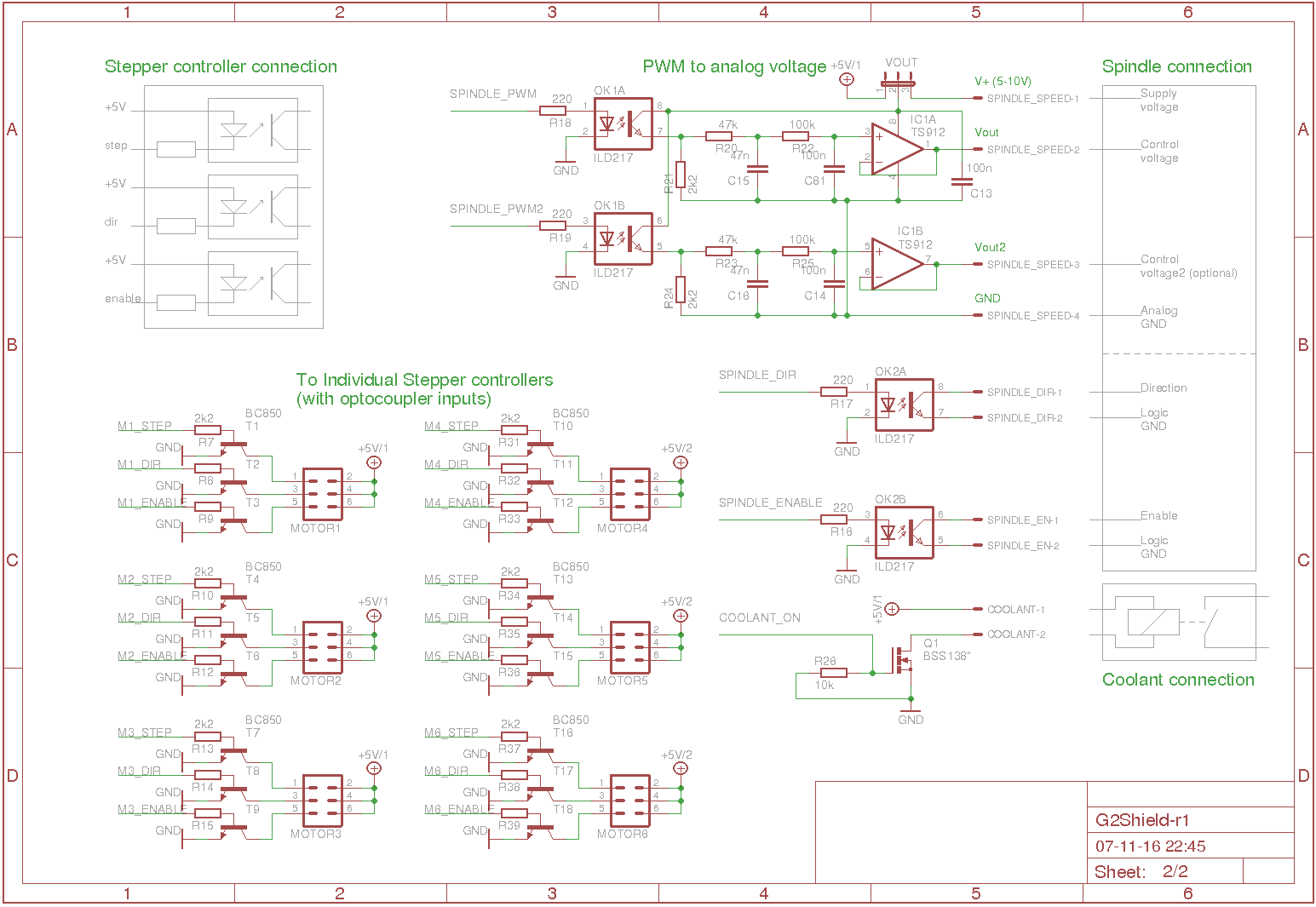

I first tried the Protoneer CNC shield with both Pololu a4988 and drv8825 drivers on a NEMA17, but they seem to overheat very quickly. Then I tried a TB6560 connected directly to the Due G2, but this gave problems with missing steps due to the mismatch between 3.3V Due and 5V expected level for the optocouplers. This was solved by adding a low-side transistor driver for each enable/dir/pulse signal after which I got very stable high motor speeds.

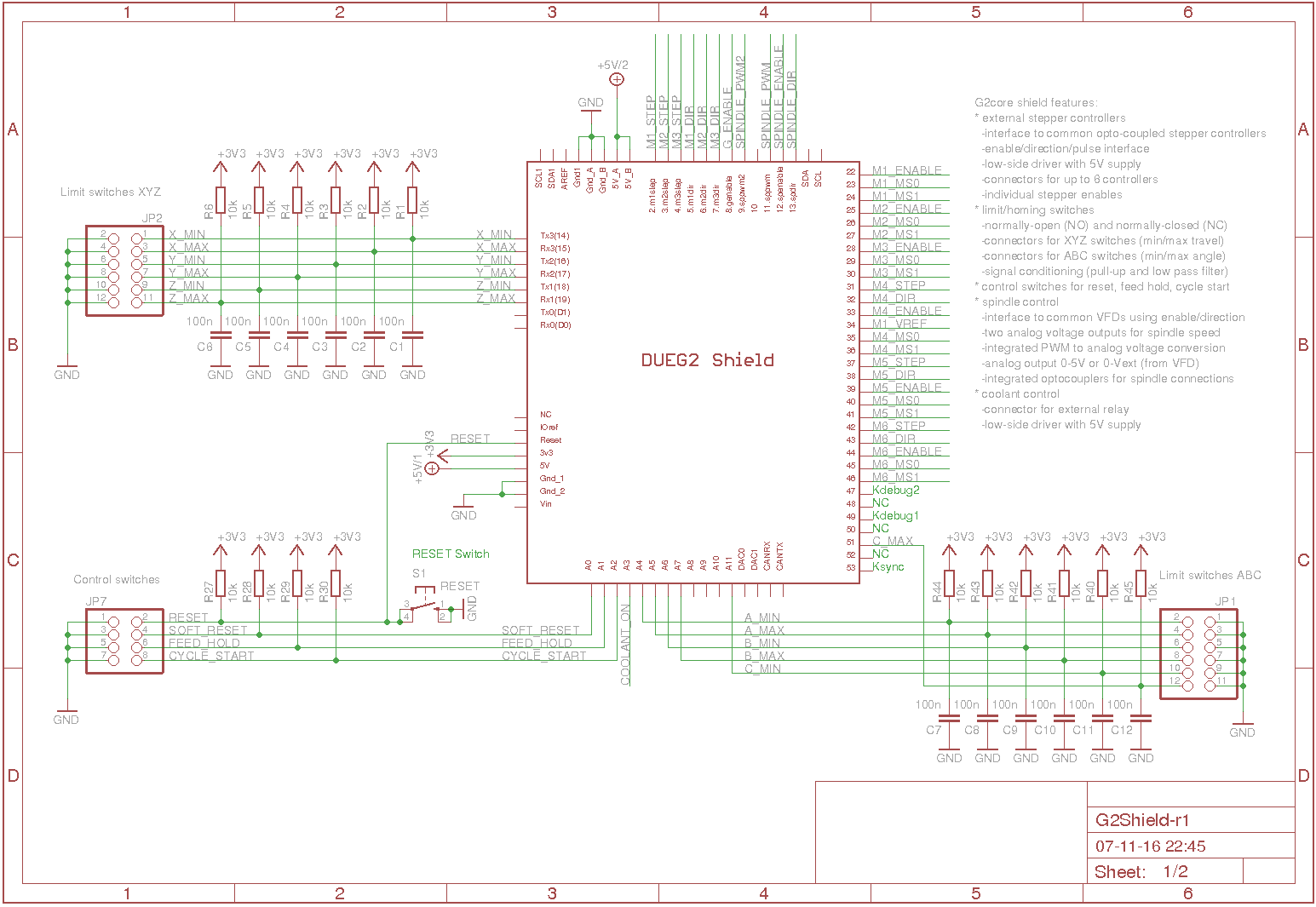

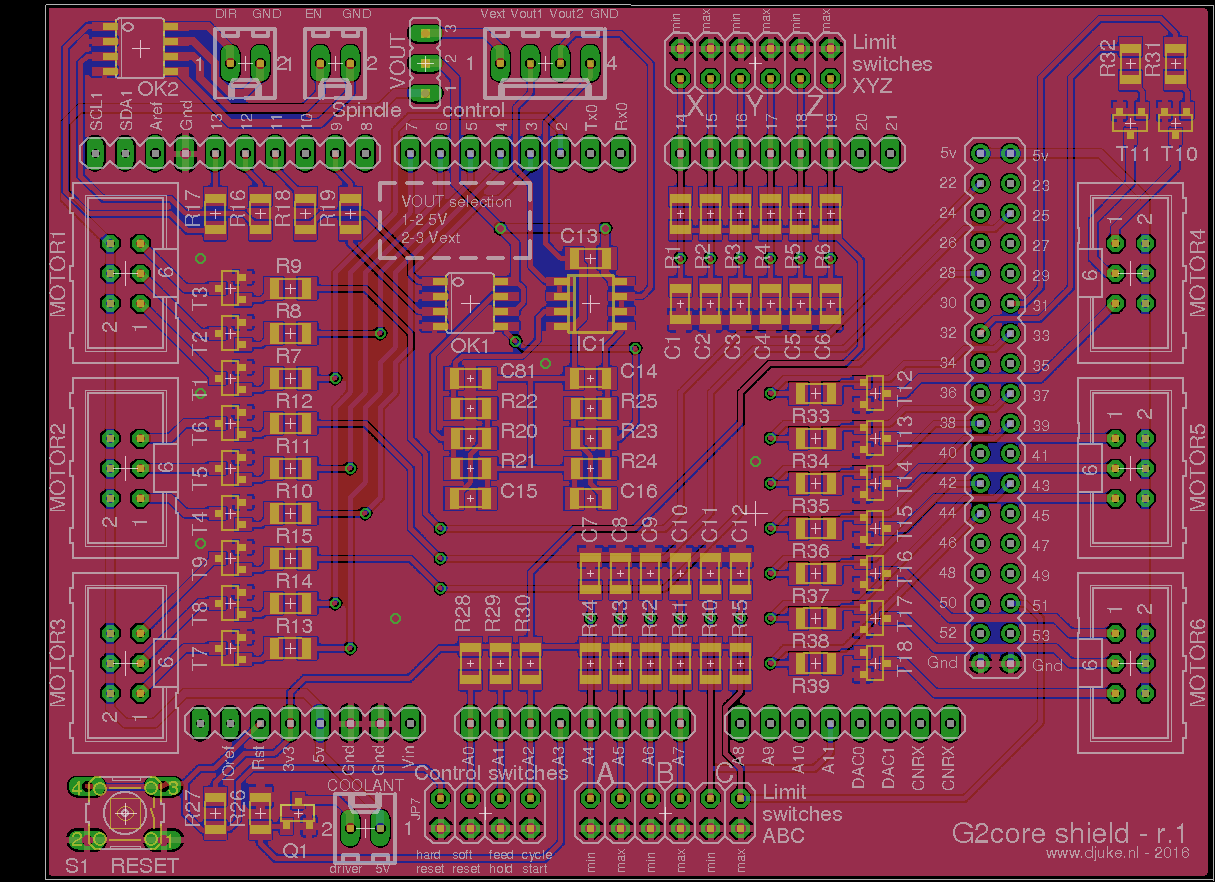

Based on the above and the idea of the G2 shield mentioned in https://github.com/labsud/GTwo, I decided to make a design for a G2 Due Shield that is more tailored to my situation:

- Can connect up to six external stepper drivers with optocouplers (like TB6560, TB6600, etc)

- Can connect limit switches for both XYZ and ABC axes and includes signal conditioning for them

- Spindle interface (enable/dir), with pwm-to-analog conversion for speed control

- Connector for coolant control relay

Hope it gives others some inspiration. Also it would be great if you could share your comments or suggestions for improvements on this design.

Thanks