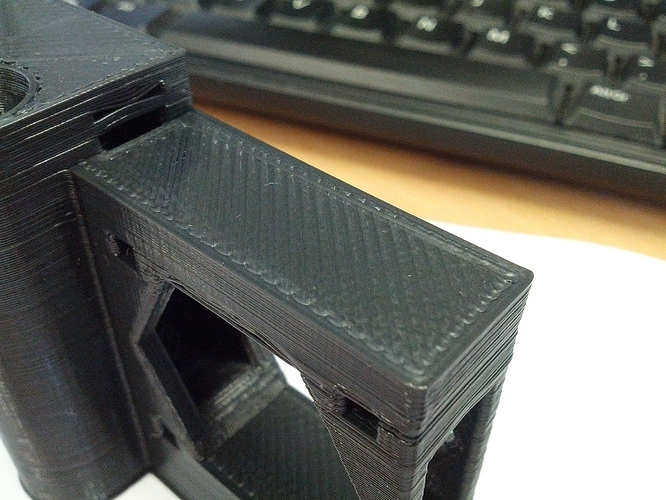

Following @ThantiK experience I decided to sand the nipple off my jhead nozzle. Its improved the quality of the solid fills significantly. I still need to address the poor bridging, retraction and add a fan but I’m making progress.

Btw; only needed for the MK-IV-B series nozzles. The MK-V’s already have this modification. Glad to see it helped your output.

It was a MK-IV-B. I bought a new one last week (MKVI?) So if it didn’t work I had a back up. I’m well pleased with the results. I only used 400 grade sand paper but it leaves the filament with a polished finish. Great little mod.

Maybe I need to try this with mine, I remember reading about it. I remember @ThantiK talking about getting the newly sanded end level with the bed. Any comments on that?

I put sand paper on the bed lowered the nozzle on to it and moved the bed back and forward by hand so it should be square to the bed. It looks like a MK VI now!

Interesting, I have a Mk IV, I guess this would make it more like the Mk V and also reduce resistance in the hot end due to the shorter pipe. What grade of paper do you recommend?

What are the odds of ruining your nozzle when doing this?

So how did you do this? Put the 400 grit paper on the bed, then move the head back and for then down, repeating until flat? Did you have to drill the hole out again after? (I have a mark IV with the big nipple as well and am not happy with the plowing that I get on the top surfaces…)

@Rob_Antonishen Exactly that method. I didn’t have to re-drill as the filament was cold in the extruder and prevented any material going in to the nozzle.

@Mano_Biletsky_Open_M I was pretty heavy handed with mine as I had a spare to hand if anything went wrong, so if you take your time i am sure you can’t do it much damage, Just go slowly and keep checking how far you have sanded, don’t be tempted to sand too much off.

@Bracken_Dawson I’m not sure with the paper but i started with 80 grit but that took too much off too quickly, so i changed for some 400 grit and the nozzle now leaves a smooth almost polished finish rather than ploughing the top of all the prints.

I wonder if 1200 grit paper would polish it furthur?

@Rob_Antonishen that’s what I did. I created a gcode file that did the motions for me. Just G1 X0, G1 X200, G1 X0, and copy/pasted that a bunch and saved it.

Then I homed the bed, did a G92 Z10 (tells the firmware that Z is 10mm above the bed, and allows you to move down) then ran the gcode with some somewhat fine grit sandpaper under it, and manually moved the bed down in 0.1mm increments until just the little nipple was shaved off. I had initially done this by hand with low-grit, and the nozzle was rounded - when I did it, it was basically to square off the sanding I had done by hand.

I didn’t have to drill the hole out afterwards.

I have the Arcol Hotend v3 i think. It came with my prusa kit. It also has this nasty square tip that makes the filament stick behind the rim. So i have to clean it very often and the tip pull’s on the printed plastic. That is when you get that sort of “hairy” or “spiky” finish.

So untill how far should you/I sand it?

Do you have pictures of the nozzle? ( before-after)

@Mano_Biletsky_Open_M I don’t know for the arcol hotend but the jhead has an obvious flute on the end that is gone on newer versions.

Thanks @ThantiK and @Daniel_Wood I filed my nib off last night and have had great improvements in the top surface of prints! Mush have changed the extruder dynamics a bit though as it looks like I need to recalibrate the multiplier as I am under extruding now…

Interesting. How much did you sand off ? Could you post a picture of the nozzle?

+1 for pictures!

I probably wouldn’t do it with the arcol.

Anthony, thanks. I indeed had my doubd’s because of the odd shape of the tip.