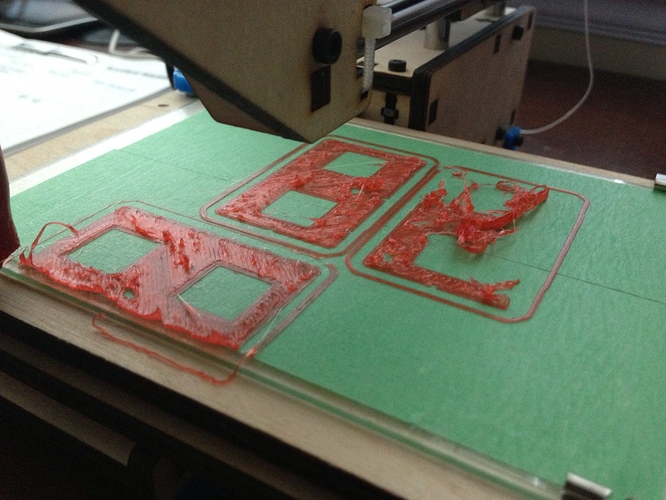

First prints with new colour PLA. Same manufacturer as my blue and green PLA, but this stuff seems to behave a lot differently. Specifically, it seems like there is too much material being deposited for the infills, so it’s globbing up and pulling away from the bed. I’m getting this behaviour with Repetier’s built-in Slic3er and with Kisslicer, so it doesn’t seem to be a slicer-specific issue. Anybody have any suggestions?

what hot end are you using?

Ubis on a Printrbot Simple V2.

Do the slic3r thin wall calibration test. You’re extruding too much.

Try lower temp. And yes, different colors of filament can behave very differently. And the next time you buy the same color it might come from a different source and you’ll have the same problem. The joys of 3D printing.

@Andrew_Litt OK, I’m extruding too much. How do I fix that?

@Shachar_Weis Dropping the temperature doesn’t work - I get really bad first layer and intra-layer adhesion, really bad stringing.

Did you measure the “diameter” of the filament with calipers? This varies as much as any other quality from filament to filament. It’s generally not round, so I take two measurements and just average them, to the hundredth of a mm. This makes a big difference in terms of over- and under-extruding.

Yes, but my calipers are only tenths (I’ve got a hundredths set ordered) so to the best of my measurement capability, there’s no difference. If it were a dimensional problem, how would you adjust? Tell the slicer the filament is larger so it throttles back?

@Patrick_Ryan

https://github.com/alexrj/Slic3r/wiki/Calibration guides you through running a test print, making measurements, and adjusting Slic3r’s extrusion multiplier to compensate. If the multiplier winds up being too great, you might have better luck with Triffidhunter’s excellent Reprap calibration guide: http://reprap.org/wiki/Triffid_Hunter’s_Calibration_Guide

The e-steps fine calibration in the second link will get you close even without precision calipers. It takes longer and is a bit subjective but works well.

New filament means small test print. As moisture, size and purity all effect the print quality.

Yep, what they said. You can use the extrusion multiplier to get a good result, then go back and figure out which of the other calibration variables is wrong. Your E motor is moving farther than Slic3r thinks it is or the material is larger than Slic3r thinks it is, or both. Your 0.00 mm calipers will help a lot. Good luck!

Thanks for the input, guys - I’ll take a look at those calibration guides and see what happens.

By the way, I’ve actually done extruder calibration using a marked segment, so I’m certain that I’m no more than 5-10% off there, and like I said, my tenths calipers are telling me the filament is 1.7mm, maybe 1.8mm. Logically, I could be no more than 10% or so off, so that’s the type of amounts I’ve been tweaking by. Just for shits and giggles, I applied a flow rate compensation of 0.7 in Kisslicer, in addition to a 1.8mm filament dimension. My infill, though still a little much, is greatly improved. I’m shocked - I can’t believe I’m actually off by 30%, even considering the effect of cumulative errors and a filament change - does this actually seem likely to anybody? Have any of you seen this size compensation being required?

Look at X,Y, and Z too. If you have inaccuracies there, you could easily get to that kind of cumulative error! Again, the calipers will help. Sounds like you’re on the right track!

Bet it is filament diameter more than temp.

Looks like the problems I had - check your starting Z height, I think you’re too close to the bed.

I switched from clear to white PLA, both from ProtoParadigm, and WOW, what a difference in settings. The heat is lower on the white, and I had a ~.96 multiplier, then the filament just started stripping. I realized that I had to tighten my extruder gear tighter, since the whit apparently was softer and the gear bit deeper into it (I haven’t installed my minimalist extruder yet). I have a Makerbot at work, and leaving all the settings the same, I’ve noticed different colors of ABS oozing more than others, but I’m too lazy to fiddle with temperatures, since the parts are 100x better than my home printer.

and you Solve not sticking by putting the temp up a Few degrees C if you put it too high with red it will Crystallize in the extruder plugging it making it useless it is 185 Degrees push it only as high as 200 any higher and you will burn it.