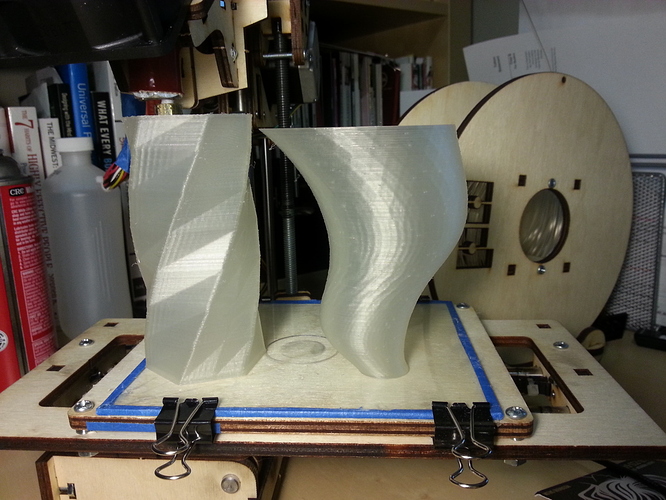

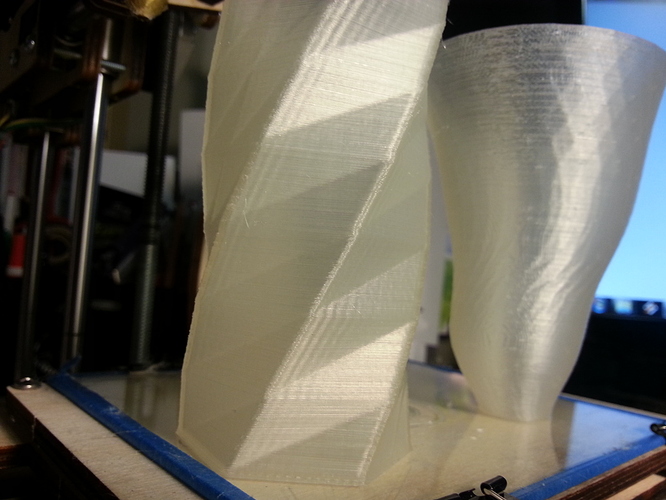

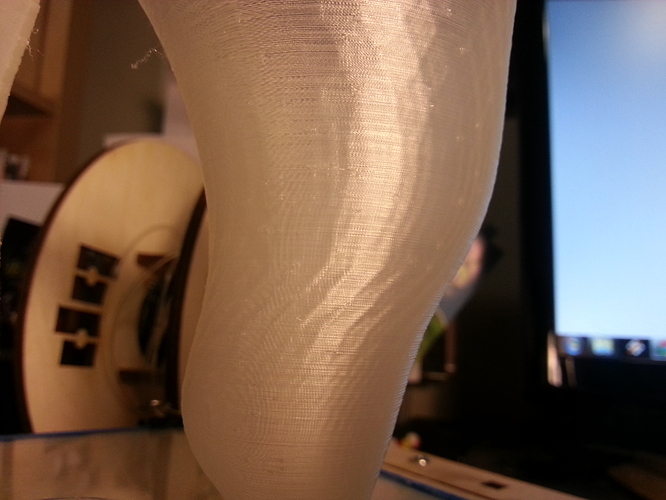

Finally was able to get a couple prints off my Printrbot Jr. without it jamming. The cause of the jamming isn’t fixed yet, but my parts to do so should be here this week. The Tornado (http://www.thingiverse.com/thing:33344) and Twisted 6-Sided Vase (http://www.thingiverse.com/thing:18672) were printed at .2mm. I had an issue with the Vase being just a little too tall for my print bed, so the last few layers were jammed down pretty bad. The Tornado was scaled to 45%, both prints used a 2 perimeter thickness.

@John_Schneider Cool. Looks like you have some ringing on the corners of the 6 sided vase so you might tighten up those belts more or run it a little slower. (Or if adventurous update the acceleration in firmware.) What’s your plan for the extruder?

Yeah, @Brian_Evans , I see em. Part of the problem is the hotend is wiggling around in the extruder along the y-axis. Since there’s just the two bolts holding them in there, I’m not too surprised. I’ve seen a couple people who’ve used a washer or two as shims and that helped immensely with the problem. I’m also going to be upgrading to GT2 belts and pulleys just as soon as Adafruit gets the belts back in stock. I’m running at 40mm/s (I think, not at home to verify) for the perimeter. As for the kinking/jamming problems I’ve been having, I ordered a length of Teflon PTFE, 1/4" OD X 1/8" ID which I’ll trim to size and glue into the space in between the hobbed bolt and the hot end, that should fix it I think.

Cool

Awesome

@John_Schneider Good idea on the tube as far as fitting it inside the LC wades. I might be able to try something like that. I just picked up some 16 tooth GT2 pulleys from lulzbot and they are fantastic. 100 steps/mm works out nicely. You might also have old Makerbot motors though on the x & z depending on when you bought the Jr… this will create a little problem because the shaft is 3/16" rather than 5mm. This means the pulleys wobble. Not cool. I was going to post some info on this but haven’t had time.

I love seeing output from the various printers we have here, it’s invigorating and encouraging and the feedback from other operators has been indispensable for troubleshooting.