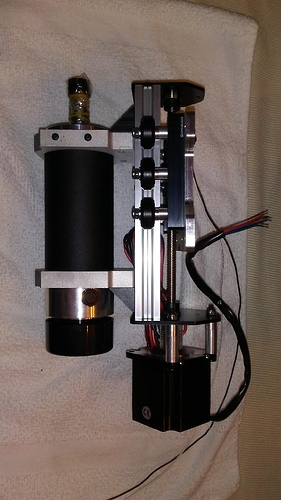

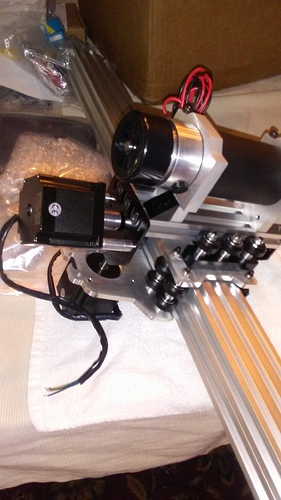

Finally getting started with my OX build. I was going to build a table for it first but just got stuck in a trance to build it. Having a little trouble finding that right balance using the eccentric spacers to reduce play in the axisies. Any suggestions?

oh, I corrected the spindle mounts. That’s what you get by just watching the video steps and not reading newer instructions.

Adjust the eccentrics so that you can just rotate the wheels with your fingers. The wheels should be tight enough so that you can easily rotate them by turning with your fingers, but still feel a good amount of drag. They are too loose if they spin freely, and they are too tight if you can’t turn them with your fingers.

Having the wheels too tight will cause premature wear, too loose and they won’t turn when the axis moves.

You should be able to grasp the Z axis motor and try to move the axis forward and back and side to side. Any play at all is too much, the whole axis should feel tight with no “clicking” or motion in any direction.

MG

@Awesome_Coder One other piece of advice, after you make an adjustment run the carriage back and forth a couple of times to redistribute the load across all the wheels, and then check the adjustment again.

MG

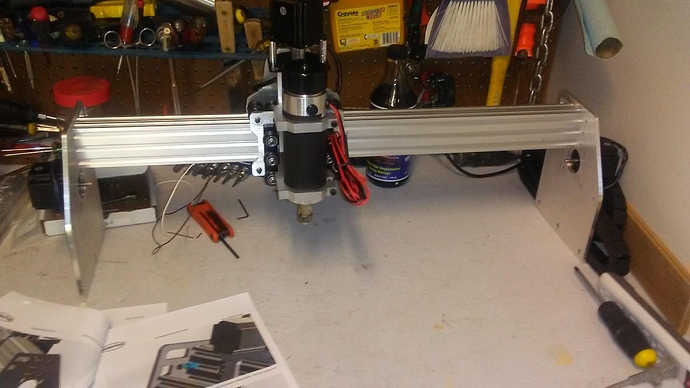

@Awesome_Coder Looks good so far. Have you decided where you are going to put your electronics? I found that to be one of the bigger challenges.

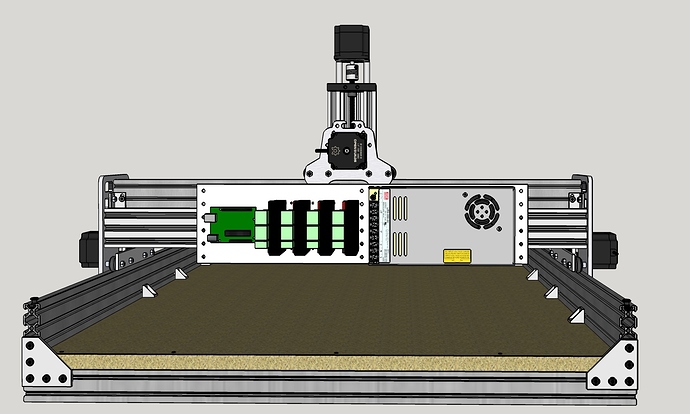

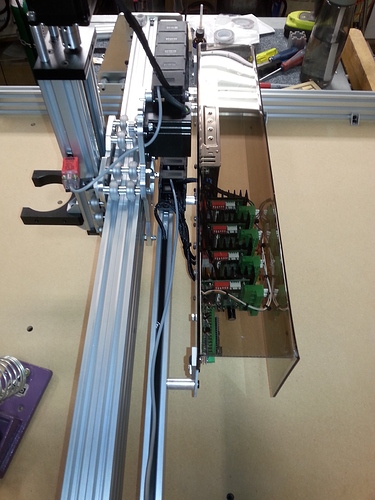

I put my electronics on a panel mounted on the back of the X axis, mounted on the brace rail. Makes wiring easy, all the motors have leads long enough to reach. The only thing coming off the machine is the power cord asn USB cable. No connectors, no extra box, all self contained.

@Darrell_n Apparently, you can only attach one image per post. I put a clear acrylic dust cover over the whole thing.

@Darrell_n I completely readjusted my Z and X wheels and feel like the motion is much better. Thank you for your help.

@Awesome_Coder just crud’s and giggles, the box can be mounted on the back of the X, spacing and holes made for it. She doesn’t have any dampers though so do not know how life will turn out later down the road.

I would just worry about all that weight and having all of the electronics (including the power supply) in the dust area. I’d be curious to see how it all turns out.

I mounted all of my electronics to a piece of MDF outside an enclosure I built just for those two reasons. You can see it at https://openbuilds.com/builds/ox-cnc-build.4523/

Scroll to the bottom and you can see part of the MDF board on the left side of the picture. I added small feet on the board so it stands vertical up against the side of the enclosure.

@Michael_Forte I’ve built probably 40-50 machines with this setup over the last 2 years, probably 20 OX HD’s (my own design upgrading the base Ox), several C-Beam Machines and C-Beam XL’s, a dozen or so Workbees, etc. All are still running and none coming back for repair.

Weight is not an issue, the whole electronics panel weighs less than a router and the weight is evenly distributed across the X axis brace. I don’t use any vibration dampers in the mount, it is very solid and does not vibrate at all.

Dust is a bit of an issue, but as long as you blow it out with compressed air every once in a while it seems fine. Never had one overheat, and there is no forced air or fan like you would need in a sealed enclosure. Everything is convection cooled, although the power supply does have a fan, it only turns on when the internal temp reaches a certain point.

As long as you have dust collection attached to the machine, there is not a problem. Dust probably does YOU more harm than the electronics…

I also find that dust is a big enemy of the polycarbonate wheels on these machines. Not keeping your tracks and wheels clean and over tightening the eccentrics are major wear promoting issues causing premature wear on the wheels.

MG

@Darrell_n That is good to hear about the weight not being an issue. The power supply isn’t exactly light but it would definitely have saved me quite a bit of space and wire if I mounted directly to the x-axis. Wouldn’t that hamper acceleration/jerk/y-speed/etc.??? If I build another one down the road I will certainly look at mounting to the cross bar. I’m thinking that if you built a simple box frame around all electronics and power supply, you could probably just cover it in something like cheesecloth to eliminate most of the dust.

@Michael_Forte Weight is not an issue. The weight of this whole assembly is less than 2Kg(4.5 lb) with power supply and dust cover. I’m guessing the the entire Y gantry is somewhere around 20Kg(44 lb) with the router, so that’s only 10% added weight. Not going to affect anything significantly.

You could make the acrylic cover a bit more of the assembly, but you need good airflow because it is not fan cooled, just convection. That’s why I left the ends open. Trust me, dust is not a problem, it is non conductive, and the only thing it would affect is blocking off some of the cooling. Just blow it every few hours and you are golden.

BTW, you can see my Big Ox Heavy Duty design on OB forums:

https://openbuilds.com/builds/big-ox-heavy-duty.4040/

MG