Some time ago, I asked , in g+ diy group, for an industrial grade cnc electronic In order to make a big 3D epoxy resin printer.

Well, the protect is under construction now.

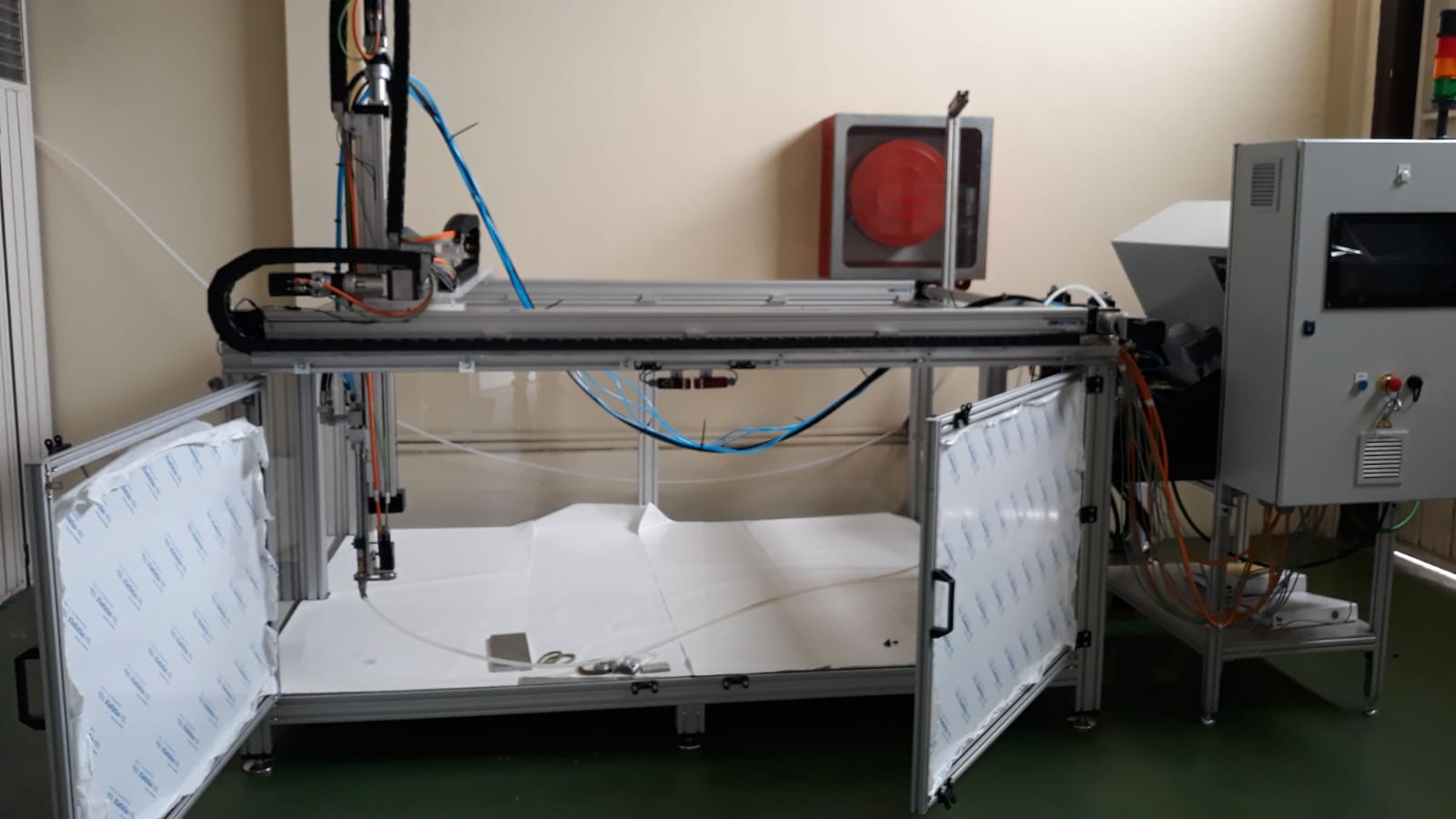

The working area it is about 1800x1200x600 mm. It is not for made at home:rofl:

The electronic cabinets are made, the linear rails are assembled , the dosing unit is ready, and I expect to finish the printer in 1 month.

I will post some photos about this machine when I found the option of add photos what the phone to this forum.

More details coming soon…

What are you talking about, this looks exactly like a home project!

Is there an epoxy that will set fast enough or do you plan on suspending it in some sort of boyancy-balanced bath?

Do you believe this? My room has not enough space to build this machine. And I have not garage.

The epoxy is under development. It is not commercial.

Is it a 2 part epoxy resin? Does it have light hardening qualities? Do you plan on adding something like sawdust to the epoxy to make it so you do not use up the epoxy as fast? Will it use a liquid hardener? What nozzle size?

I was thinking that 1/4 inch nozzle opening for an epoxy sawdust mix should allow for making of chairs with an acceptable strength without clogging the nozzle up. Of course, the nozzle will have to be cleaned between prints to remove residual epoxy. If the sawdust is not mixed with the epoxy, the part could be dusted with sawdust just as easily and the sawdust that is not encased in epoxy could be collected for later use.

Hello.

The epoxy resin is 2k compound. 1 part is resin and the other is the hardener .

Hardening is induced by chemical reaction after mixing both parts with a static mixer. The viscosity is arround 500.000 mPas. The resin is under development.

May be added, in the future, fiber glass, in order to do the compound more strong.

The nozzle is 1 or 2 cm square. The maximun flow can be arround 2,5 ltrs/min, and the movements of the 4 axis will be 2 mtrs/seg.

If you are thinking in mix sawdust with resin, the bigest problem can be to pump the sawdust at the exact quantity. For the chemical reaction to occur, the 2 compounds have to be dosed at the correct mixing rate. It is very important.

For the cleaning, there are 3 options:

1.- thow away the mixer, after use.

2.- clean the mixer pumpig only the compound A (no rective part)

3.- clean the mixer with solven, and then blow with air.

When the chemical reaction starts, there is an open time, in this time you can clean the mixer and work with it. After this open time, if you did not clean the mixer, it will be block.

If you want to make chairs with sawdust, will be a good idea pre -mix the part A with the sawdust first. For pump this fluid, a screw pump will work well. For the B part, a gear pump will be enough.

Wow! This is impressive. I’ve been looking at resin printers and didn’t think about making one. Please keep posting your progress. thank you.

Since it is epoxy, I imagine you would not have to worry about epoxy from carbon fiber skinning damaging any prints you wanted to skin. This other dude was carbon fiber skinning PLA prints but I would have to wonder what interactions PLA would have with the epoxy he would use for skinning.

https://www.3dprintingmedia.network/you-too-could-now-3d-print-a-lamborghini-aventador-at-home/

Thanks. The proyect is in test fase now. Yesterday the first work was printed, with poor quality.

But today, the printed was good. The especial epoxy is working. It is the first formulation.

Will be more info next weeks.

Hi.

At this time the inclusion of charges in the chemical formulation is not planned, because the dosing unit works with gear pumps.

There is a proyect to make other dosing unit with screw pumps in orther to include fiber glass or similar, but not at this moment.

The project looks great.

My dad ran a company doing epoxy casting for high voltage insulators in the 1960s and 70s. He found that he needed fillers to add the strength and stability, so made a mix of silica (sand) and epoxy as it reduced the price substantially.

I would probably go with disposable nozzles - perhaps soething like the ones that come with silicone caulking tubes. You need to make sure that the components are well mixed otherwise they wont set. And I mean really well mixed at the microscopic level.

Most of the comebacks he had selling small quantities (Pratley was not around yet - it was developed by another guy sharing factory space with him) was a result of inadequate mixing.

Cleaning up with epoxy around is never an option, you will have to produce at a rate faster than the epoxy can harden on the edges of your extruder. PTFE or UHMWPE might be giid choices for lining the extruder. Perhaps a blow moulder that produces plumbing tape can assist.

I look forward to seeing your results.

Very interesting… I probably do not have your experience with the epoxy resin… but after my experience the faster the accelerator boosts the reaction the more precise the components are to be dosed together. So I would probably think about a two cylinder system where the cylinder diameters define the different percentage of each compound. I also would think that a labyrith mixer would soon be sealed by the partially hardening resin ( if it would be so fast).

Or if one would be able to design the chemistry from scratch, to implement a non chemical starter like uv light, heat , externally applied (catalythic) activator.

Well, actually the dosing unit is working very well with gear pumps. The actual ratio is 1.9:1 and the time necessary to harder the mixture is about 2 minutes when a infrared heater is used. The dosing unit needs gear pumps because if it is necessary to change the ratio, it will be do very easy.

Using pistons is more complicated. The ratio is changed replacing one of the cilinder. Maybe is the most precise system, I know it. whit gears pumps the flow does not stop any time and I can made very big pieces with a constan flow.

A second dosing unit is coming in order to be mounted with a Kuka robot, it will not be a Cartesian system.

I’m actually using a commercial dosing unit, and the price is very expensive.

I am planing to make my own dosing system using an arduino plc.

If some one wants help coding, let me know, because I never programmed an arduino, and will need help.

Wow nice, so its something bigger. I have some experience with casting motors and e - equipment under vacuum conditions using PU 2k resin. With both piston and volumetric pump principle

as dynamic and static mixer… Greatest problem of the static mixer is the different viscosity of A and B compound. So with time in production the hardener is creeping along the outwalls and so the mix is not consistent anymore… so the tube has to be replaced from time to time. At least using PU.

Regarding your idea… some guys in our lab were working on a similar printer but with slightly different materials, but I just can show what’s on the web availabe…