Does anyone use a Z probe with their printer? Would you care to share your leveling results?

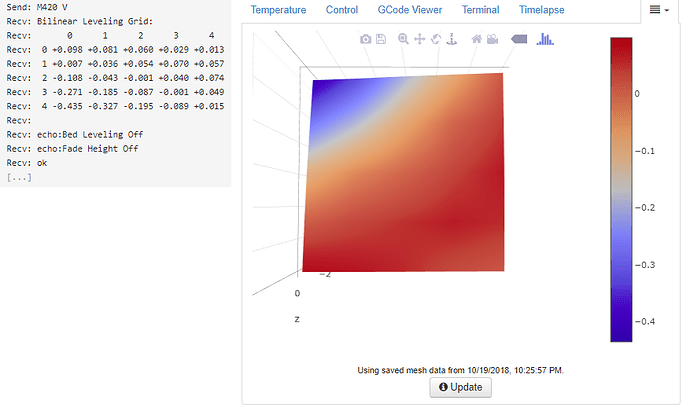

I get a dip in the corner that I can not seem to get rid of. I am starting to think its mechanical or motion related. I get the same basic result with both 3point and 4point leveling.

This is the Bed Visualizer map of a brand new 1/4 piece of Mic6, no glass. I threw a straight edge across it and I could not see any light leaking under it no matter which way I put it. Short of spotting it on a surface plate, I would say its flat enough. I changed the differential IR sensor to a plain simple Omron lever switch like I used for the endstops for now.

I am using the Bilinear bed leveling in Marlin, I even went as far as 5x5 grid.

I have turned the plate 90, 180 and 270 degrees. I flipped it over and did the same thing. I basically get the same pattern of hi’s and low’s. The iso-lines may move, but the same general shape. I would think that if it was switch related, I would seem lots of variation in the readings.

How rigid is your Z platform? If you push on a corner, does the platform flex? If so, in which way? I am wondering if its related to flex or movement induced by the play in the LMU bearings or Z screw.