Does anyone here have a machine that can cut a rectangle 654mm x 663mm?

Yes i have one cnc router that does 790 x 790

@Ariel_Yahni_UniKpty would you be willing to give me a quote if I supply you with dxf files? Are you in the USA?

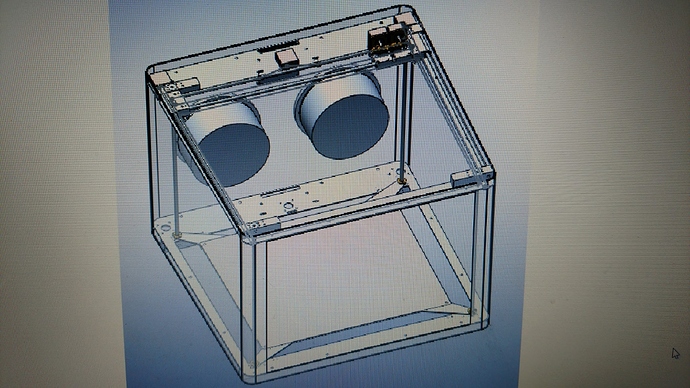

+Peter van der Walt I wish that I could build one right now. Just ran out of money trying to prototype a 434mm cubed duel print head build volume. Its a CoreXY/Hbot design. Heres a picture.

What material and what thickness?

@Alex_Krause I am open to others like plywood if you think it will work and be cheaper. This is just my first prototype for this design.

@Ariel_Yahni_UniKpty thanks for taking a look. Besides interesting, what else do you think? I know it’s kind of hard to see all the details in the photo. But I would like to know what you have to say.

So this that you need its for that printer? I would really work on play maybe first until you are sure of the design. Whats important about a design like yours are the parts on the gantry and the way you will tension the belts plus Z axis should be held and secured from multiple side not cantilever style, specially on a large build plate

@Ariel_Yahni_UniKpty The bed is mounted between 4 speed screws in the corners. I think I have worked out a good way to tighten the belts. I am not sure about play in the gantry yet.

@Alex_Hayden

I can cut aluminum with a plain old circular saw. There’s not much to it really. But I don’t use my best blades when I cut stuff like aluminum. Any rough use carbide tipped blade will do.

@Alex_Hayden

ah OK. You’re talking about cutting the bottom of the frame out? When I have to cut inside square holes in metal I drill out the corners, then I plunge cut the long cuts, and finish with a jig saw. I clean everything up with files afterwards. Whenever you cut metal you’re pretty much going to be filing, unless you use a water jet. Or you just don’t care about burrs.

Sometimes I’ll chain drill really heavy stock. Here’s a weird shape in steel that I decided to chain drill http://i.imgur.com/Zf6Qp5o.jpg

It’s a bit more complicated than a simple rectangle too. Oh, and that’s quarter inch thick steel.