Cooling the laser tube is critical to not burning it out. The recommended temperature range is narrow. Getting this right is hard or expensive; getting it wrong is repetitively expensive.

TL;DR

This article is too long to read. What can I do to stop worrying about it?

Buy a refrigerated cooler such as a CW-5000, CW-5200, or LO-600W / Q600W with a cooling capacity at least 5 times the max power of your laser and at least 6 times the maximum continuous power you will use, hook up all the alarms including temperature, and call it a day. It might cost as much or more than your K40. If this bothers you, read through for more information. There are other options, but they are more work, and some of them depend on your location or luck scrounging. Note that a CW-3000 is not a refrigerated cooler and is not appropriate for lasers.

Short Form Q&A

Q: Why does the tube need to be cooled at all?

A: The US$100-$150 laser tube can die in as little as a few seconds without cooling. If you don’t cool them enough, they quit working in a short time.

Q: How much cooling is enough?

A: Enough cooling to keep your cooling water bucket under 20C/68F and enough pumping to keep about one liter of water per minute flowing through your laser tube.

Q: No, I meant can I use the pump that comes with the laser and a bucket of water?

A: Maybe. It depends on the pump and the bucket of water. And your hose path. Always, always place the end of the return hose under the water surface in the water bucket.

Q: Can I use tap water for cooling? I’ve seen people using tap water, distilled water, and special recipes for cooling water. What works?

A: You can use some tap waters, if they are very soft. Distilled water (without added minerals) is better. Some additive recipes are OK, others are counter productive and can cause damage.

Q: OK, how can I keep the cooling water reservoir cool enough?

A: Most K40 users will need to refrigerate the water somehow. Here are some of the ideas that K40 users have tried:

- Add frozen water bottles to the bucket. (recommended)

- Use a CW-5000 or similar water chiller. (recommended)

- Ignore cooling the bucket, just circulate the water at whatever temperature. (hope you like buying new tubes)

- Run tap water into the bucket

- Re-purpose an office water-bottle style cooler.

- Re-purpose a miniature refrigerator.

- Use Peltier/electrothermal panels.

- Use a computer CPU water-cooling radiator

- Use a CW-3000 “water chiller.”

- Use an aquarium water chiller.

- Scavenge a used window air conditioner.

- Live in a cold climate.

Q: Why is there a minimum temperature for the cooling water? Why can’t I run cooling water at 15C? 10C?

A: Doing this flirts with causing thermal expansion/contraction cracks in the glass.

Q: How much heat is generated?

A: The K40 has to get rid of 160W to 200W of waste heat

Q: How much water and at what temperature do you have to circulate?

A: Move about liter of water per minute through the K40 tube, and cool it to between 18C (64F) and 20C (68F) in the cooling tank.

Q: Can the little aquarium pump that came with the K40 pump enough water?

A: Probably, if you don’t arrange your plumbing to prevent it from doing so. Always make sure your return hose end goes under the water level in the coolant bucket. Keep in mind that you have to cool the water in your bucket, too, as well as running the water through the laser. Use the largest practical cooling water tank. Most people seem to use four to five gallons and that works well.

Q: Do I need temperature and water flow interlocks?

A: Pumps and chillers fail. Only a single failure will most likely kill or substantially degrade your laser tube. Interlocks cost less than a new tube.

I want to understand more

Great! Let’s go down the rabbit hole together!

Why do they need to be cooled at all?

If you don’t cool them enough, they quit working in a very short time.

The electrical arc that excites the CO2 to lase also rips up some of the CO2 into carbon monoxide and oxygen. These two poison the ability of the remaining CO2 to lase. Laser tube designers can set up the tube so that the CO and O2 will recombine into CO2. Getting a long life out of a sealed CO2 laser tube is a delicate balance of using it without running it so hot that the gasses are permanently poisoned. For a specific laser tube, driving it hard (high power/current) and letting it get too hot internally hastens its eventual death.

How much cooling is enough?

Enough cooling to keep your cooling water bucket under 20C/68F and enough pumping to keep about one liter of water per minute flowing through your laser tube.

The laser tube makers recommend water at 18-20C (64-68F) and about 1 liter per minute. Actually, the laser tube designers for the K40 laser tube didn’t say a word about it, because no one knows who exactly they are. The 18-20C temp is a common recommendation from other laser tube makers, and the 1 L/m is based on commercially available 80-100W tubes. But they’re really good guesses.

No, I meant can I use the pump that comes with the laser and a bucket of water?

Maybe. It depends on the pump and the bucket of water. And your hose path.

One liter per minute is pretty modest circulation, and the aquarium style pump that comes with the laser is probably capable of this, as long as you don’t make them pump the water too high above the pump. Aquarium pumps can generally not pump any water higher than a few feet upwards.

Always, always place the end of the return hose under the water surface in the water bucket. This creates a siphon effect which makes your pump work much better.

The common five gallon bucket of water is a fine solution if you can keep the water down to the recommended temperature range. Four to five gallons (16-20 liters) of water make a fine coolant reservoir. But you also need to contrive to keep that water cool.

If you don’t refrigerate the bucket of water somehow, the water will eventually be the same temperature as the air around it. If that air around the water bucket is down at 18-20C, you’re good if you let the bucket cool down to air temperature between laser runs and don’t run the laser for hours, then you’re probably OK. If you live someplace hot, where “room temperature” is over 20C/68F, the water starts above the recommended temperature. I (@keen) live in a place where the outdoor temperature is regularly 38C.

Can I use tap water for cooling? I’ve seen people using tap water, distilled water, and special recipes for cooling water. What works?

You can use some tap water, in rare locations with very soft water. Most tap water has high mineral content or chemicals that make them less desirable for cooling a laser. You obviously don’t want mineral deposits on the glass tubes inside your laser. That could ruin cooling in spots, and lead to glass failure. Also, tap water is highly conductive, which may itself be a problem. I’ve read a couple of places that the conductivity of the water may encourage internal arcing. One place even supposed that early laser tube failures could come from high conductivity encouraging arcing. Tap water is usable, but I consider it to be a field expedient, what you do when you can’t get the right stuff in a hurry. Conductive coolant can destroy the laser power supply.

More research is clearly needed on that topic, but I have a simple and pragmatic view. Distilled water is available locally in my grocery stores in the baby food section for about US$1 per gallon (but avoid distilled water that has had minerals added). I can’t think of a good reason NOT to use distilled water over the long term. If you don’t have distilled water easily available, you can make distilled water with a tray of wet stuff, a bottle, a pane of glass and some time spent building. This is the classic solar distiller.

There are many, many DIY solar distiller links on the web, some as simple as two used soft drink bottles. Here’s a decent starting place: diy-alternative-energy.com

I classify the magic coolant recipes I’ve found into three groups: those intended to get rid of bubbles, those intended to prevent freezing, and those intended to prevent algae growth.

Algae growth is a problem, as it interferes with water flow directly, deposits on the glass, prevents heat transfer, and on and on. Algae (green gook) growth is bad. There are aquarium additives that kill algae, and some that seem to not make your high-resistance distilled water more conductive. Tetra AlgaeControl has been tested to not make your water more conductive. A few drops of the right stuff in several gallons seems to be enough. Tetra AlgaeControl appears to be unavailable in Europe, but Tetra’s AlguMin has been reported to work well. Bleach is not recommended.

Anti-freeze is problematic. These can easily cause problems with conductivity.

Anti-bubble potions get a lot of press in the laser community. I have yet to find one mentioned where someone didn’t come along and say “I tried that and it didn’t work.”

OK, how can I keep the cooling water reservoir cool enough?

Most K40 users will need to refrigerate the water somehow.

The quick, certain way to keep the cooling water tank cool enough is to use ice to cool it. One reasonable way to do this is to save half-liter or liter plastic beverage bottles, fill them with water, and freeze them in a refrigerator. ½ Liter/16oz of ice melting in a water bucket will absorb enough heat to run the K40 at maximum power for about 15 minutes without the water bucket heating up. There are other ways:

-

Ignore cooling the bucket, just circulate the water at whatever temperature. This works anywhere from sometimes to mostly. However, there is a steady flow of posted complaints about how quickly laser tubes wore out. Most people who simply use a bucket with no special attention to temperature probably don’t run long lasing jobs, and it takes a long time to heat 5 gallons of water. I call this technique “you bet your tube”.

-

Run tap water into the bucket and let it overflow into a drain. In many places, the city tap water is 68F/20C or colder for much of the year. It’s wasteful of water, but it works. Water quality is a problem, as city tap water often contains lots of dissolved minerals and other things you’d really prefer not to put in your laser tube.

-

Re-purpose an office water-bottle style cooler. These can often be had for between US$50 and free. They can work, but have issues. In general, the problems come down to how fast the units can remove heat. The manufacturers’ documents on water coolers are remarkably un-enlightening. I did a pretty solid search on the web and found no manufacturer’s literature that said how many watt-seconds or BTUs per hour that they would move. The literature only says that it will “cool” thus-and-such water in this time. That would be great, but nowhere do they say what temperature the incoming water was before cooling, and what temperature “cool” is. This makes it impossible to figure the heat moving capability. Some people use them, though. Maybe there are extra large capacity coolers that are big enough. I can’t find info on that though.

-

Re-purpose a miniature refrigerator. The manufacturers’ literature that I could find indicates that they are limited to about 20W to 100W of heat removal per second, so they’re probably not able to keep up with the K40 running continuously. However, if you can put your 5 gallon water bucket inside them and cool that water overnight or for some hours, the water in effect stores up the cooling and can run the laser for a longer time before overheating.

-

Use Peltier/electrothermal panels. Sounds good: put air on one side, your cooling water on the other side, and pump electricity through them. The cold (water) side gets cold, the hot (air) side gets hot, and heat is pumped from the cold side to the hot side. They actually do work this way, but the practical matters of how big/many panels are needed to pump enough heat fast enough, and the kinds of fans and pumps needed to move air and water around, and the big aluminum finned heat sinks for the air side make this a difficult thing to do. Like office coolers and mini-fridges, anything you do for cooling will help. But Peltiers have a hard time keeping up with the heat output of a K40 at any kind of reasonable price and effort. And they take a modestly large electrical power supply to drive them to do the cooling. The laser power supply itself doesn’t have enough spare power to run Peltiers suitable for enough cooling. And it is very easy to burn them out; they do not survive even short over-heating.

-

Use a computer CPU water-cooling radiator placed over an air conditioning cold-air outlet. Most ACs in good condition produce cold air at about 62F (16C) and if you get enough water flow and air flow and the radiator is big enough, the AC will keep the water cold. I admire this solution, but have not tried it myself. The trick will be getting enough water flow in the radiator, a big enough radiator, and enough cooling air flow from the AC.

-

Use a CW-3000 “water chiller.” There are lots of these on ebay for US$150 and up, marketed for cooling lasers. The problem is that they are not chillers. They are radiators that blow room temperature air over your cooling water. If your water is cooler than room temperature they will actual heat your cooling water. In my opinion, they’re a waste of money. Be aware that these are often counterfeited/copied.

-

Use a CW-5000, CW-5200, LO-600W / Q600W or other water chiller that has actual compressor-based refrigeration and is rated for cooling water. Great solution, one of these will take care of the full cooling load of a K40. A CW-5200 will cost US$500 or so. Be aware that these are often counterfeited/copied/cloned.

- Choose one that has cooling capacity at least 5 times the max rated power of the largest tube you might upgrade to.

- Running refrigerated coolers constantly will eventually cause them to freeze, just like home AC coils. They need to cycle off sometimes. So also make sure it has cooling capacity of at least 6 times the highest constant power you will use over a long time. The more humid your climate, the more important this is. It might not matter much in Arizona, but in Florida it might matter a lot, especially if your laser cutter runs in an unconditioned space.

-

Use an aquarium water chiller. Good idea, but expensive. Bought new, about US$500 and up. May be a fine solution if you can get one used for cheap. Like the CW-5200 and its ilk, these will reliably handle the heating load if they’re running right.

-

Scavenge a used window air conditioner. Outstanding choice for being cheap and for having enough cooling capacity. The smallest window ACs have several times the cooling capacity needed by a K40. The trouble is getting that “cold” from the evaporator coil that gets cold and into your water. There are DIY descriptions of how to hack one of these and bend the evaporator coil over into water, or build a water tank around it. Ultimately, this is a huge amount of work. Maybe combining this with the CPU radiator would work.

-

Live in a cold climate. Good idea, makes cooling easy. Room temperature is likely to be down in the 18-20C range anyway, so the laser is happy with just a radiator. But you will have to worry about the cooling water freezing. This is an unpleasant end for a laser tube. And if you don’t already live a cold place, moving might be more expensive than a CW-5200.

Why is there a minimum temperature for the cooling water? Why can’t I run cooling water at 15C? 10C?

Doing this flirts with causing thermal expansion/contraction cracks in the glass.

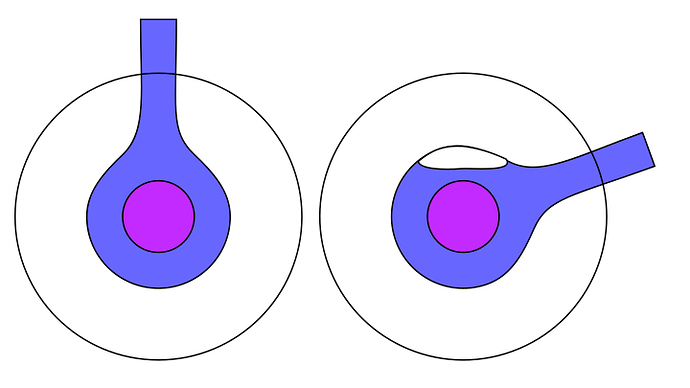

The innermost glass tube contains the lasing material at a power density twice (or more) the density of the actual external beam and also contains the 10,000V electrical arc that excites the gas to lase. It’s really hot inside that tube. The next tube out contains the reserve gas, where the tired (Lase-y? ) gas from the inner tube goes to rest. The outermost tube contains the cooling water. It’s job is to keep the middle reserve gas tube cool enough for the CO and O2 wastes from the lasing gases to recombine into CO2 to live to lase again. With very hot gasses and glass on the inside, and cold water on the outside, all meeting at the ends which make the tube supports, the temperature differences get critical.

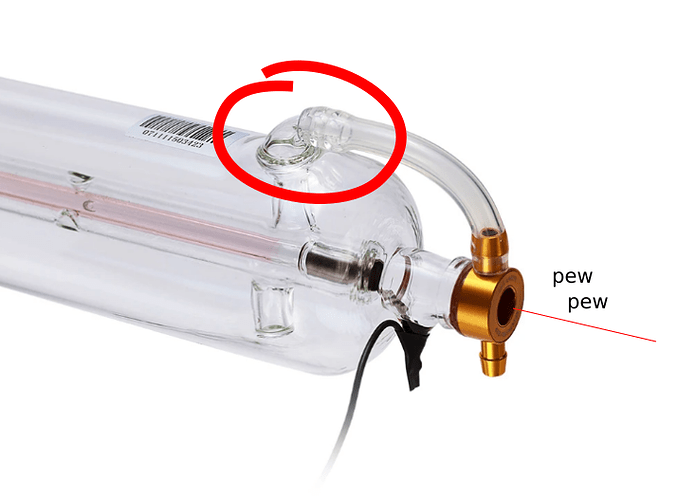

Air pockets in the cooling water also create thermal stresses. If you move or replace your tube, make sure that the water exit (near the ground wire, where the laser beam exits; the cathode) points up, and make sure there are no stationary air pockets in the tube.

The Technical Explanations for All the Above

It’s a universal truth that the amount of energy and matter you put into something will equal the amount of energy and mass coming out. This gets complicated by burning fuels and by nuclear processes, but for something like a K40 laser where we put in electricity and get out light (that laser beam) and heat, it is simple. Pretty much, all the electrical power you put in has to come out of it as heat or light.

So if you put in the 300W or so of electricity these things take to run, and get out 40W of light in the laser beam, all the rest of the electricity eventually heats up the machine. The whole point of running cooling water through it is to carry heat away so that the machine doesn’t heat up inside until something dies.

This is the ultimate goal of cooling: carry away as much heat as is generated.

How much heat is generated?

The vast majority of the heat is generated in that laser tube. Most gas lasers convert 1% to 2% of the electricity to laser beam. CO2 lasers are remarkable in that they can convert electricity to laser beam power at up to 20% efficiency.

But turning that around the other way, CO2 lasers need cooling because about 80% of the electricity you shove through the tube is converted to heat. Only 20% (if you’re lucky and things are tweaked in properly) comes out as beam power. You have to get rid of the 80% that’s waste heat. If you don’t the gases overheat, chemically combine, eat molecules off the glass, melt the glass, and in general stop being useful.

If you put out 40W of laser light, and that’s 20% of the total power into the tube, then the total power into the tube must be 200W and the remainder after 40W leaves as laser light is 160W. There is a lot of room to quibble with that number, because K40’s say they put out 40w, but the reality is probably more like 30, max. However, K40’s lowest-bidder laser tubes are also unlikely to hit the magic 20% efficiency, either. So the waste heat is probably a bigger proportion of the total. Until I can find better numbers, I think the K40 has to get rid of 160W to 200W of waste heat in the cooling water.

How much water and at what temperature do you have to circulate?

The makers of the K40 lasers don’t say. They just send that little aquarium pump. But researching other laser tube maker’s recommendations, you can find some numbers. The clearest recommendations came from a respected maker of replacement tubes. For their 80W-100W laser tubes, the same glass-tube style, they recommend cooling water at 18C to 20C and 2 liters per minute of flow. I based my guesses for the K40 tube around that.

I reasoned that the gasses would be similar inside, and that the glass tubes, electrodes, and end mirrors would be very similar, so the temperature recommendation should be the same. I also reasoned that a tube rated for around half the output power ought to generate about half the heat, and so could make do with half the water flow, about 1 liter per minute.

This is a very thin basis for a guess, but it’s about the best info I could find. And it seems to give reasonable estimates for other things. In the absence of better reference numbers, flow about liter of water per minute through the K40 tube, and cool it to between 18C (64F) and 20C (68F) in the cooling tank.

Can the little aquarium pump that came with the K40 pump enough water?

Probably, if you don’t arrange your plumbing to prevent it from doing so. Small aquarium pumps do come rated for substantial flow rates, but they cannot produce much pressure to force water against flow resistances. A large and hidden pressure resistance for small pumps is the height the water has to be pumped to.

If the stock pump is roughly level with the laser machine, it’s probably OK. Putting the laser up on a work bench a couple of feet above the coolant bucket means the pump has to pump the water both through the hose resistance of the machine and also up a couple of feet of height. It doesn’t sound like much, but that 2-3 feet of height may be nearly all of the pressure the pump can produce, so not much is left over to move water through the laser. Many aquarium pumps flatly specify that they can’t pump water any higher than four to five feet, period. At that height, their pumping stops entirely. Below that, most of their effort is expended pushing the water up, not running it through the machine.

There is a trick here, though. If the pump can just manage to get the water up into the tube and get water running out the outlet hose, and you put the end of the outlet hose under the cooling water level, the suction of the water falling from the laser coolant bucket pulls the water behind it, and reduces the pressure on the pump, which now doesn’t “see” the pumping height. The moral of the story is: always make sure your return hose end goes under the water level in the coolant bucket.

How much cooling water is needed? Is one/two/four/five gallons enough?

Now it gets complicated. The short answer is that the less “reserve” coolant you have in your cooling bucket, the better and faster you have to cool the water bucket.

And very sneakily, you probably just noticed that you have to cool the water in your bucket, too, as well as running the water through your laser. There are at least two things that have to be cooled.

Ultimately, the laser is cooled by either the air in the room around the water bucket, except for a few unusual cases. The cooling water is a fast and easy way to move the waste heat out of the laser tube to keep the tube from dying. But if the cooling water gets too hot, it doesn’t cool the laser enough and the laser dies more or less slowly. So the cooling water has to get cooled, too.

But water stores more heat per unit weight than any common substance. It’s a great heat reservoir. The more water you have in your cooling bucket, the longer it will take to heat the water up, and the longer you can run the laser without overheating. If you think about it, the oceans are a bucket, although a very large one. Imagine that your pump is pumping water out of the ocean, through the laser, and back into the ocean. How long would it take to heat up the ocean?

Correspondingly, the smaller the reserve water tank, the faster the laser will heat it up. If you have only one gallon (about four liters) of water in your cooling tank, it will heat up five times as fast as if you had five gallons of water to heat. So use the largest practical cooling water tank. Most people seem to use four to five gallons and that works well.

Now it gets picky. To keep your laser cooling water down under 20C, you will have to work out how to cool the water, and how fast.

Water is a great way to store heat. There are two common ways to express a certain amount of heat/energy, the Joule and the BTU. A Joule is one watt for one second. We can substitute the term “watt*second” for Joule. A BTU (British Thermal Unit) is the amount of heat needed to raise the temperature of one pound of water by one degree Farenheit. As always, you have to convert the units to make sense of metric and Imperial measurements.

Back at stored heat, water has a specific heat of 4.186 Joules/gram*C. If the K40 is making 160W of water heat, it does that every second, so it makes 160 watt-seconds or Joules per second. That amount of heat would raise one gram of water (1/1000 of a liter) by 160/4.186 = 38C on top of whatever temperature the gram of water already was. And it would rise another 38C the next second. If you had a total of 1 liter (1kg) of water to cool the laser, it would heat at 1/1000 that rate, or 0.038C per second, and 2.28C per minute. But we can use a lot more water. Let’s say we have 4 liters (~ 1 gallon) of water to heat. The 160W raises it by 160/(4000*4.186) = 0.00956 C every second. If our water started out at 20C, in one minute it would heat up by 0.573C, and it would do that every minute we ran the laser.

Using four times as much water, 4 gallons (~16 liters) cuts the heating rate by four to 0.14333C per minute. So – the more cooling water reserved, the longer you can run your laser without cooling the water itself. If we have 4 gallons (16L) of tank water and 1 liter in the tube, the output of the tube would heat a (roughly) 17 liter mass of water by about 0.135C/ minute. Ten minutes is 1.35C, and an hour is 8.1C. A big water reservoir heats slowly.

Most of the foggy recommendations I’ve seen say that your cooling water should not get above that 20C number. If you start with 20C (68F) water, and four gallons of it, it gets to 21.43C in ten minutes, 22.86C in 20 minutes, and 24.3C in 30 minutes. If instead, you had started at 30C (86F, which we get all the time where I live), you’d have water at 34.3 C in 30 minutes. This is danger territory for tube life.

A lot of people simply use an un-cooled bucket of water at whatever temperature the air sits. The heating numbers show how they get away with this. If they do a short (30 minutes) lasing session, their water only heats up a bit over 4C, and the tube does not die immediately. But it does shorten the tube’s life at the far end, the bit of its life you can’t see yet.

If you only use the laser for short (~10-15 minutes) sessions, and will never use it for much of the 1000 to 5000 hours it is capable of, you may not need to cool your cooling water bucket.

If you want long tube life, and plan to use up all the hours it has in it, then you need to cool the cooling water. Plan to try to keep the cooling water down to 20C. There are many ways to do this, as noted before. But the simplest, cheapest way to do it is to freeze plastic soft drink bottles re-filled with water. A 16 oz/ 0.5L bottle has enough “cold” stored in the frozen ice to eat up the total heat output of a K40 for about 15 minutes as it thaws. So dunking one of these in you coolant bucket until you get the bucket down to 20C, and dropping in another every 15 minutes of lasing is a pretty good — and cheap! — way of cooling your laser’s water. The other means mentioned earlier work to the degree that they can remove 160W per second from the cooling water.

Thoughts about ice

As amazing as water is, water changing state from fluid to solid (ice) and from fluid to gas (steam) is even more amazing. It takes energy to change ice at 0C into water at 0C. A lot of energy. Water takes 4.186Watt-second/gram*C to heat. Changing ice at 0C to water at the same temperature, 0C, takes 334 W*S/g*C. And that is from 0C to 0C – a constant temperature. Your laser puts out 160 W*s per second, or 9600 W*s per minute. That melts 28 grams of ice. A half-liter of water is 500g. Melting that takes 500*334 = 167,000 W*s. So your laser’s 9600 W*S/min needs 167000/9600 = 17.39 minutes.

Ice is readily made and stored in modern refrigerators. You can put your refrigerator to work making ice and keep all those little bottles of 15 minutes of laser cooling just sitting there, waiting for you to need them.

What about using thermoelectric/Peltier coolers?

I have looked at Peltier/thermoelectric devices for cooling and didn’t think I could use them well. Thermoelectric devices are tricky. they work best at low temperature differentials, and have a Coefficient Of Performance that as a practical matter peaks out at about 1.2 (if I read the charts and graphs correctly) for a device working at about 0.3 of its maximum current.

Uh…Right? So what does that mean? Well, If you pick a small temperature differential ( that is, cooled thing to external temperature difference) under about 20C, you can actually get a Peltier to pump out as much heat as you put into it to do the pumping, perhaps a bit more. That is, you spend as much electricity to do the pumping as you move heat energy from the cold to the hot side. The hot side has to get rid of both the moved heat and the electricity you put into the cooler to do the moving, so you have to remove twice as much heat from the hot side as you pump out of the cold side.

So at a temperature difference of 20C, if you run the Peltier at about 1/3 of its max current, you pump just a hair more power out of the cooled thing than you spend doing the pumping. So to get rid of the 160-200W from a K40, and to bring that down to 10-20C under room temperature air, you would spend about the same amount of power doing the pumping as you remove from the laser; you put in 160-200W of electricity, 160-200W of heat gets pulled out of the water being cooled, and you have to supply heat sinks/radiators that will reject 320-400W of heat from the Peltier itself. The technical thermodynamic term for this state of affairs is AAAAACK!!

Worse, since the Peltiers are most efficient when running at about 1/3 of their rated power/current, you need Peltiers rated at a Voltage X Current of 900 to 1200W so you can run them efficiently. That gets expensive. So do the heat sinks. I can see that you’re already looking at fan cooling the Peltiers. Good. You’ll need it. When I looked at this I was thinking I’d circulate water on the hot side of the Peltiers and run this through some water-to-air radiators and fans to keep the high side temperature down. The radiator will have to be hotter than the surrounding air to transfer heat into it, so that’s another step which can poison the efficiency of Peltiers.

As I said, I wish you good luck. I thought the design task was beyond my ability to do well.

Why the tubes wear out and die

[In] Commercial sealed CO2 lasers […] you can’t just take an axial flow CO2 design, seal it up, and expect the laser to work for more than a few minutes. The discharge process breaks down the CO2 to produce CO and O2 which quickly poison the lasing process. There ARE a number of solutions to this problem including the addition of other gases like H2 or H20 (water vapor) to the gas mix to react with the CO and O2 to regenerate CO2 or the use of a high temperature (300 °C) cathode to act as a catalyst to stimulate recombination.

The K40’s sealed CO2 gas mix gets hot when you run the 20kV arc through it that powers the lasing. CO2 gas mix is generally CO2, helium, and nitrogen. The helium and nitrogen are not passive bystanders. The nitrogen is actually driven by the arc discharge, and emits photons that are the perfect size to pump the CO2 just right to lase. Helium has a high thermal conductivity; it’s in there to help conduct the waste heat out of the nitrogen and CO2. The CO2 is ripped into CO and O2 by the driving energy, and this stuff will not lase like CO2 will, so it “poisons” the tube’s ability to put out laser power. The only reason this stuff lases for more than a few moments is that if left alone, it will mostly recombine into CO2.

Early CO2 lasers simply ran a flow of fresh CO2 gas mix through a laser tube and exhaust the “poisoned” gas to the atmosphere. The super high power industrial lasers still do, because the high temperatures of the arc that puts energy into the CO2 to lase and the inefficiencies of the conversion to optical power out cause a lot of waste heat. Lasers in general are notorious for how poorly they convert electricity to laser beam. Very high gas temperatures apparently prevent the CO2 from lasing at all and even “normal” operation degrades the gas somewhat.

here.

here.