Completely frustrated new to 3D printing user…

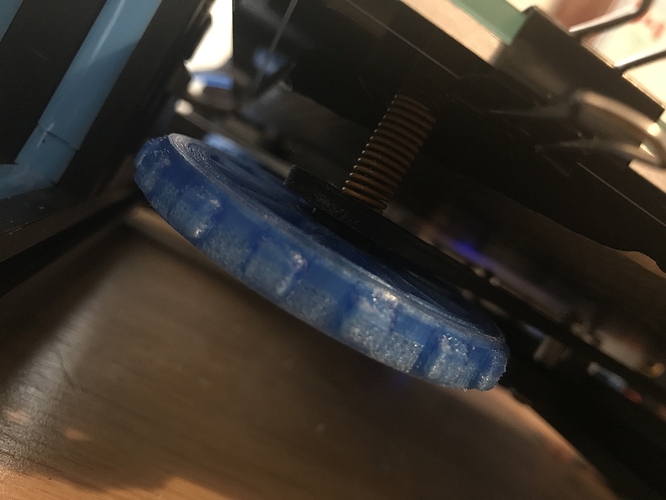

Hello everyone, I am new to 3D printing and have had some issues working out the basics to which I seek your help. After lots of research, I purchased a Creality CR-10S and some CCTREE PLA filament that was suggested by the vendor (Which seems pretty decent especially compared to the free roll with the printer). My issues are with the end product of the prints as you can see in the pics. Although the biggest issue I have is that prints keep failing around 20-40% of the job time. I have played with bed temps from 50-70 and nozzle temps from 190-215. I have also tried hairspray and glue sticks for the glass bed adhesion which I prefer the hairspray and think that this is working fine. The blue translucent filament levelling wheels came out ok, but the first half is very nicely made where the top half seems to have been too cold and is more brittle.

Please help…

This looks like retraction generated heat creep to me as it seems that the issue starts after trying to print separated areas of the print. Could also be time related which would indicate an extruder cooling issue.

PID tuning issues can cause this type of result as well. Does your temperature cycle up and down during the print?

What are your slicer settings for retraction? Distance and speed?

If your problems are happening at a specific height, or around the same height you might have an odd angle on your filament getting to your extruder which causes it to be tugged more and decrease the flow rate or cause adhesion problems. You could also be dealing with temperature differences between close to the bed and if there’s air moving around the printer. You probably want to try and do some calibration prints in order to both make sure that the printer is calibrated but that you also know the best slicing settings for your filament that you purchased. You can do something as simple as print a 20 by 20 by 100 column and vary the temperature and flow rates as you print the column. You can do this in Cura. That will help you in one print kind of discover the best finish and adhesion, the strength, in one print. you can also check that you are printing things with an accurate dimension at the same time.

Creality sometimes has a weird issue with the Bowden tubes. Check out this video that explains the possible issue and fixes. https://youtu.be/x35aWmnZ_A0

https://youtu.be/x35aWmnZ_A0