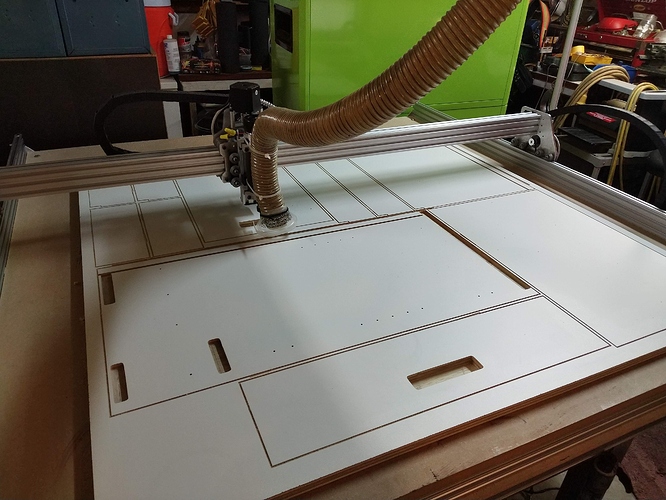

Cabinet parts! I had to give up on having the router cut everything out. Now she just traces the outlines for me. Less opportunity for failure.

Can I ask what problems you had using your CNC to actually cut the part out instead of just drawing lines?

What controller are you using?

All-in-one Pro, which is a RaspberryPi / Arduino hat running GRBL. A lot of struggle there, and I am close to abandoning it for something more stable/responsive. The GRBL doesn’t seem to be the problem, rather the poorly documented bCNC sender has been a struggle. The Rasperry Pi is working, but limits choice of sender to bCNC, as, nothing else will render on the Pi.

The Nema 23 steppers with mere ounces of torque, driving belts, have so little power. The spindle doesn’t bog down, rather, the bit resistance quickly overwhelms the holding torque, and chaos results as the bit climbs through the work. I tried shallow cuts, multiple passes, and everything is sub-standard. I cant wait to get into a screw-axis machine.

One success story has been the use of 0-flute bits. they track better with less chatter.

bCNC is poorly documented. They really need some volunteers there. I will likely jump in when I have my pi running. As far as holding torque goes you should be able to dial it up. At least on my controller there is an adjustment for torque and I can also run over voltage to the motors. I can run a 1/4 inch bit 1/4 inches deep in plywood without problems and consistently trace the same lines. I would gladly help as I think the all-in-one pro was heading down the right path. I have the hardware and the software for it but I am still lacking the cabling.

@Jonathan_Roeder One thing to check in your settings within bCNC is $1= Set it to 255 ( $1=255 ) That will give full power to the steppers. I personally changed my stepper motors on the X and Y axes to 420 in oz nema 23 motors. The belt will slip before the motors do now. I had them from a previous build, so I figured why not.