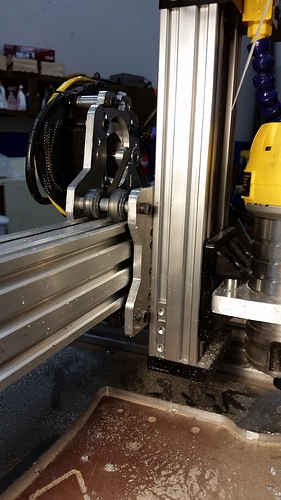

C beam linear actuator z axis! I couldn’t really find a good way to do it looking through the group, so I tore down the ox. I was trying to find the most solid mount possible so I could cut aluminum better, so I drilled four holes in the front x carriage lined up with the channels in the c-beam and used t-nuts to hold it solidly. The only downside was I lost the inside set up wheels, but I didn’t even notice it. Was a night and day difference! I wish I would have done this months ago.

Do you have less twist around the X axis? That’s my problem really with the X. Spindle is heavy, and the whole asembly rotates a little around the X axis due to the fact it’s held only by 2 sets of rubber wheels…

@Michel_Pollet I do have x axis twist, but it’s not TOO bad. It did get a little worse when I removed the inner wheels for this mod, the whole assembly just moves more then it used to- but the rigidity gained in the z was well worth it.

I found that adding an extra layer or two of spoil board really helps out with machine stiffness. It allows the spoil board to flex less, and it moves your work up closer to the x axis. This minimizes the leverage on the x beam