problem is that I only probably can order parts from china, because amazon is to expensive… and delivery time is still ~15days.

I dont want risk ordering LPS and turns out tube was broken. Is it logical to simply order tube and LPS?

is this set good enough or it needs to be cloudray?

Sorry but I have no experience with this vendor so I do not know.

Anyone on here from outside US, have advice for @Nieksas

But by specifications it should work?

【PRODUKTPARAMETER】 - CO2-Laserröhre: Ausgangsleistung: 40 W, Länge: 1830 mm

It’s extremely unlikely than an 1830mm tube either fits in a K40, is actually a 40W tube, or is part of a 150€ bundle, so the listing is most likely not correct here.

maximale Ausgangsspannung: 23 kV, maximaler Ausgangsstrom: 20 mA

Suffices for a K40.

From that page, one other important thing:

https://www.amazon.de/MagiDeal-Analog-Panel-Meter-Amperemeter/dp/B07CZ1MNXZ

This is cheap insurance to help you not burn out a new tube. ![]()

It’s probably mistake in description, because I’m specifications and photo it’s says 700mm.

But as vendor is good choice or need to search for particular band or to upgrade to something better?

It doesn’t look like there’s a lot of experience on the forum one way or another:

https://forum.makerforums.info/search?q=vevor

As far as I can tell they are just another reseller. The use of the “【” and “】” wide square bracket characters in the amazon listing is typical of listings made directly by Chinese companies, due to translation.

Unless you get a great package deal I would just start by replacing the LPS, then go from there.

So if I understand correctly what you trying to say is that there is no big difference if I buy, cloudray or VEVOR its almost the same thing but with different stickers? ![]()

LPS from different supplies also look exactly the same. At least on out side

One more question. When I get new LPS how do I connect it to tube? because I saw in amazon seller saying that simply connect old wire from tube to LPS new wire and wrap it with installation tape?

I am buying, please if you can check so I didint make miske choosing

So glad you asked! That advice sounds potentially fatal. Normal electrical insulating tape typically has a “dielectric strength” of 600V and is useless for 20000V on the laser. The only way I can think of that being good advice is if they are providing special high-dielectric silicone tape with the tube. This exists but isn’t normal.

See Laser safety: Light and Electricity which both links to @donkjr’s blog with details on connecting and splicing, and features a video from Lightobject on splicing.

Thanks for the answer, it probably saved my life literally ![]()

Although almost everything that is important has been said, I also want to cement some of the most important things.

Always connect the laser machine, and if in use the cooling machine, to a proper ground connection, this is the most important thing for one’s own safety but also essential for the machine, here especially for the controller.

Always use only distilled water. If an open container is used, a little bactericide should be used, the water must be changed before deposits appear on the inside of the laser tube. (the problem hardly occurs in closed systems such as CW500 and the like)

Always pay attention to air bubbles, the big ones but also the very small bubbles. A bubble the wrong place in a laser tube can ruin it.

Always check your ammeter and respect the max power values (35-40 Watt = 16 to 18 mA max)

Take care of your eyes.

Good luck with your renovation of your K40

I want to thank everyone for amazing help, consultations, and advises. Learned a lot from you. Thanks again

Hope new parts will solve everything

Hello everyone,

received new LPS, did a test shot at 45% and I am not sure if the beam is very nice. I bought a new tube as well, is it worth trying a new one?

It’s a bit nicer than earlier.

…at what point in the beam path are these taken?

from laser tube to the first mirror. Cleaned tube lens and it looks better. So might be a false alarm… Need to align everything, and check how it cuts

at 40%

Definitely clean everything and do an alignment.

I upgraded mirrors, lens. Installed ammeter. and it still not great.

This is an image from tube to the first mirror

I tried to find focus, but it’s horrible…

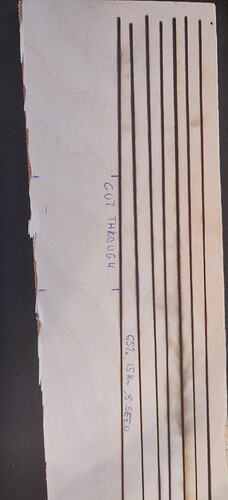

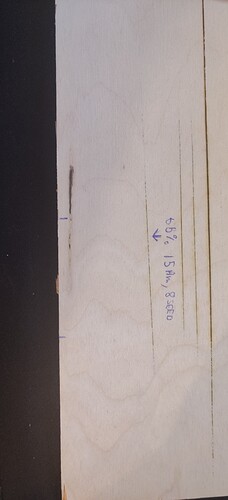

I use 3mm premium laser plywood. It used to cut at ~25% power, now it takes 65% and it leaves a mess…

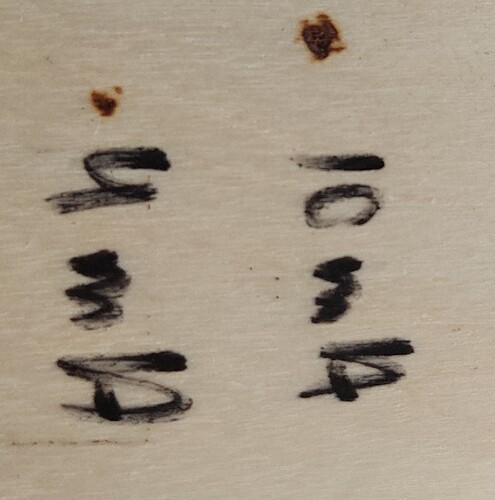

Images below 65% (15mA), 8 speed, one pass. I am afraid to change the tube, because if it’s not helping I am f…

the beam goes center of the laser head nozzle.

beam now almost always goes two though the centre of anode ring.