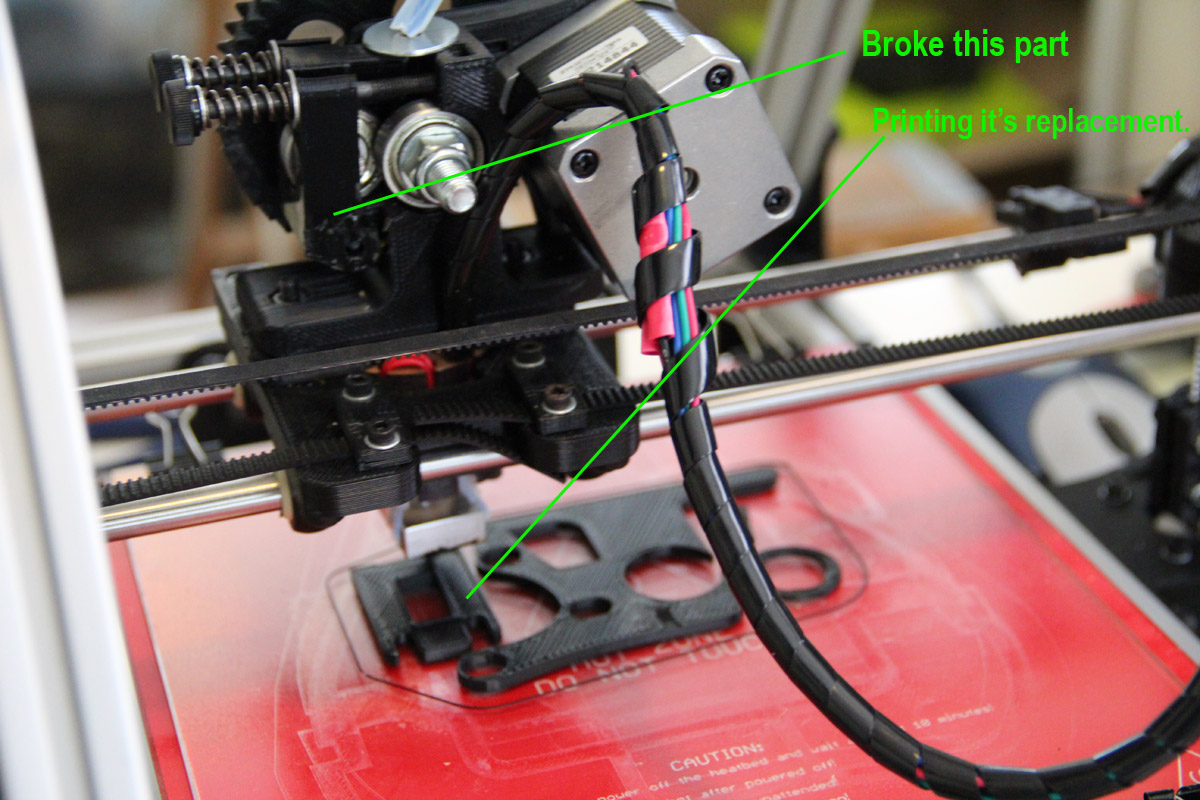

Broke a critical part. (my fault from over tightening)

Temp fix with glue.

Now printing it’s replacement.

I’ve done this several times. The idler is very prone to breaking because it has to sustain so much pressure.

Printception?

Ok soooo. A machine … Fixing a machine … Sounds familiar for some reason… Hummmmm

Hey I really want to get into 3d print … Anyone in the Phoenix area already doing it that I can chat with?

You can strengthen it with acetone slurry before you install, so it will hold up to more over-tightening. It’s also better than glue for this type of repair.

Correct. You should never, never, never print an extruder mechanism out of PLA.

I wouldn’t trust a PLA groovemount running at PLA temps with a fan. It begins to soften at far too low a temperature. I’ve also had motors that were running pretty warm, but well within spec, destroy their PLA mounts.

I just finished a new extruder. This time i processed the idler and other small parts with aceton vapour. It’s surprising hoch much stronger they become that way, also they look better

The slurry method is probably better for strengthening because it’s more concentrated acetone in one place, so soaks in deeper and strengthens more of the plastic. But yes, the vapor thing will add strength with a minimal effect on geometry.

If its abs, you can weld it with acetone some pressure and a little time.

I think that’s the beauty of 3d

printers that can replicate themselves

I’ve run my PLA groovemount for some time without any kind of problem from overheating. No fan, either. (Except for lately, to help with print quality) Maybe you just have steppers that run hotter? The hot end doesn’t seem to be an issue. I do, however, mount the groovemount with a thin piece of wood sandwiched between the extruder and the x carriage.

My first Idler split too, I had tightened the springs to 60% on the advice of another who felt 40% was to light and could the cause of my hobbed bolt slippage I was experiencing at the time.

I took the chance to replace it with a 50% infill printed ‘Guilder’ version rather than the plain Idler. My old one lasted just long enough to make a good replacement. When fitting it I discovered the cause of the slippage was a loose extruder motor gear. Since then I have returned spring pressure to the lighter setting, and filament feed has been fine.