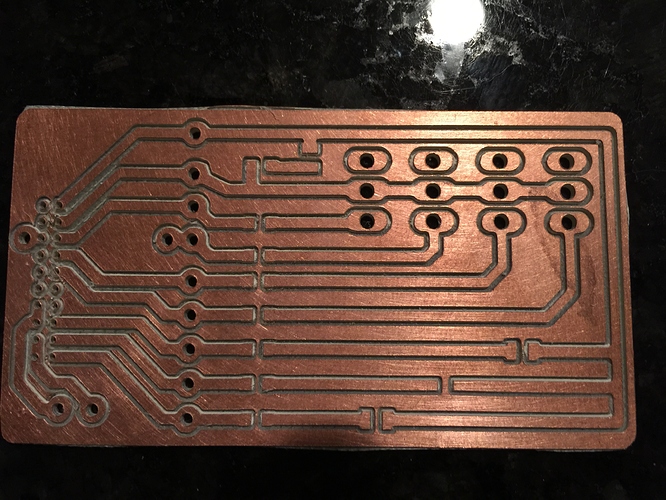

Best results yet using my 1Mx1M @ShapeOko with a 0.03" drill mill and @ChiliPeppr with auto level. Eagle to gerbers to Cambam.

Nice. What spindle you using?

very nice. would be cool to see an end to end walkthrough of how to do this starting with eagle! i have a lot to learn.

Very nice. Have you tried ChiliPeppr’s Eagle brd file import?

I really need a process for using KiCAD, none of the post processors I’ve used so far have resulted in anything worth cutting. Any suggestions anyone?

What cutting parameters did you use?

@Ben_Delarre Dewalt DW660. @jlauer not yet I I plan too. Perhaps next board. @John_Anderson 0.35mm per pass 0.7mm DOC, F=165mm plunge=85mm. This was my first time using the .03" bit so I was conservative side but didn’t seem unreasonable in practice.

Oh wow. Wonder if I can get that result with mine… If so I won’t have to invest in an othermill! Thanks @Brian_Beebe

@Ben_Delarre It looks to me like most of the inaccuracies are from my structure and not from my spindle. Cut width is pretty darn close to 0.03" (using common low grade sliding calipers) but I can see some path slop. I think a more rigid machine would be required if I I were to route for fine pitch parts.

Would you be willing to post the Eagle CAM job file? I can’t coax the CAM job into generating through-hole pads with holes in them. Cambam will pull in my Gerber file and figure tool paths for isolation routing, but the through hole pads in the Gerber are solid, so I can’t tell Cambam to route the holes.

@John_Anderson I put it in my drop box here: https://dl.dropboxusercontent.com/u/2533490/2LayerForCamBam.cam

I opened the .drl file in CAMBAM and it made drills for me but I had to adjust the tool and the hole diameter to match. Then I had to merge the cambam files to combine the routing and drilling the CBFileMerge.py script (https://dl.dropboxusercontent.com/u/2533490/CBFileMerge.py) found on the CAMBAM forums.

You can use FabModules ( http://kokompe.cba.mit.edu/downloads.html ) to import the EagleCAD BMP (PNG) output and cut a PCB without all the manual labor. I made a video for using the Roland Modela, but you should be able to select “PNG to Gerber” and export the gerber files. Here’s my video to show a similar process: https://youtu.be/0nmB0-F6ObA

Here’s a tutorial of where someone used KiCAD and fab modules for a shopbot: http://fablab.waag.org/archive/fabricating-big-circuit-board

This cut is really nice. Can you share some additional settings.

Type of bit (Flat or angled)

Bit size (.03" .762mm) that’s wide for most circuits.

Trace Isolation width

Trace width

Isolation Single or multiple passes

Depth: .7mm (2 passes)

Thanks.