Belt issues 281|18

It started when i wonder that shapes are distorted - but not always.

Turns out only if i print them in the middle.

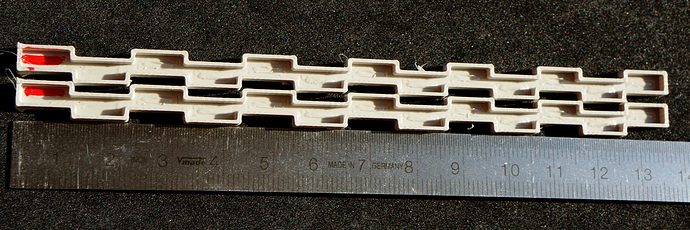

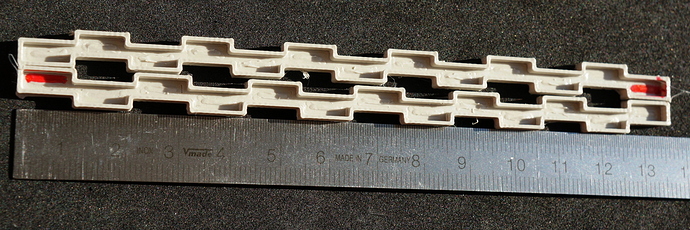

What happened was that some segments of the teethed belt become streched and didn’t fit into the grooves so the diameter of the pully changed and so the dimension of the print. (part of the belt 10 teeth were as long as 11 at a different location)

Took me a while to find out what was wrong. But with a calibration bar it is easy to detect.

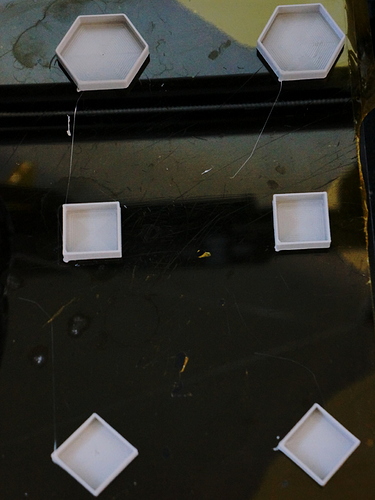

Just print it twice and hold them together - one turned 180°

or just measure each notch. You need to print them horizontal and vertical for each belt X/Y if those are seperate - On coreXY or H-drive i think a diagonal print is best.

You can download this bar from my side https://sites.google.com/site/ulrichbaer/tips/3d-print/Kalibrierstreifen.stl