Hi all,

I am new to lasers. Just bought a k40 used but with most all of the upgrades I wanted including a cohesion board and air assist. I downloaded lightburn yesterday and have been going through the manuals they have to try and learn as much as possible.

The machine worked when I bought it.

A few things I am having issues with off the bat that I can’t figure out and can’t seem to find through search is the following:

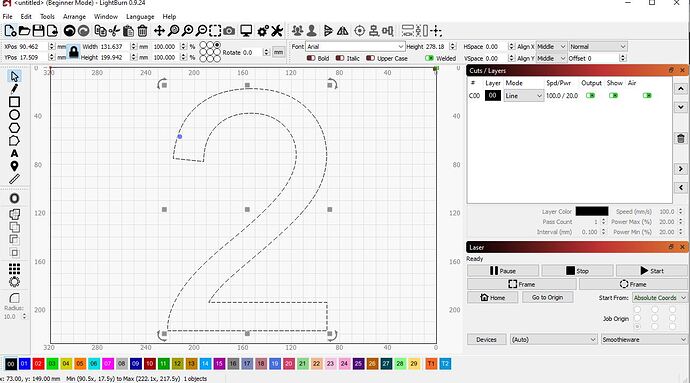

- my laser seems to be inverted with regards to how I see it on my laptop. This means when looking at the laser, the back most left side is actually the bottom right of my laptop. When I Have the machine run a program it goes in the reverse of what I expected. How can I correct this?

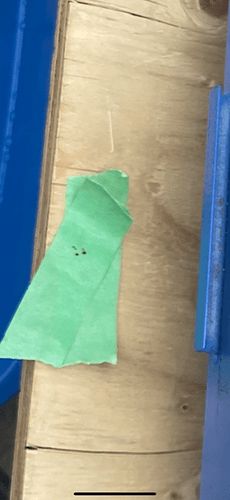

- When I have the laser “form” the area. Sometimes it only runs half the cutting area rather than the whole thing.

- If I set the image in the middle of the work space and run it, the laser seems to want to run it in one of the corners instead of the middle.

- How can I control the power output of the laser in lightburn? Is there a setting? (I have the dial on my machine that I will keep under 15ma

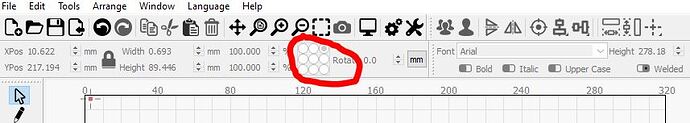

The board originally came with grbl ltc but I just upgraded to smoothie firmware (what a nightmare as I thought it was just download and go.

Looking for a little guidance and some readings. Lots of the starting stuff has been around safety, I got that all down pat.

Thanks in advance!

The guy gave me a drag chain that I want to install too that I need to search as well.

Take care…

Take care…