I am seriously considering using BBs as idler bearings in my extruder design. They are really smooth, cheap, easy to source and seem to roll easily enough in a plastic groove. Am I nuts to be considering this?

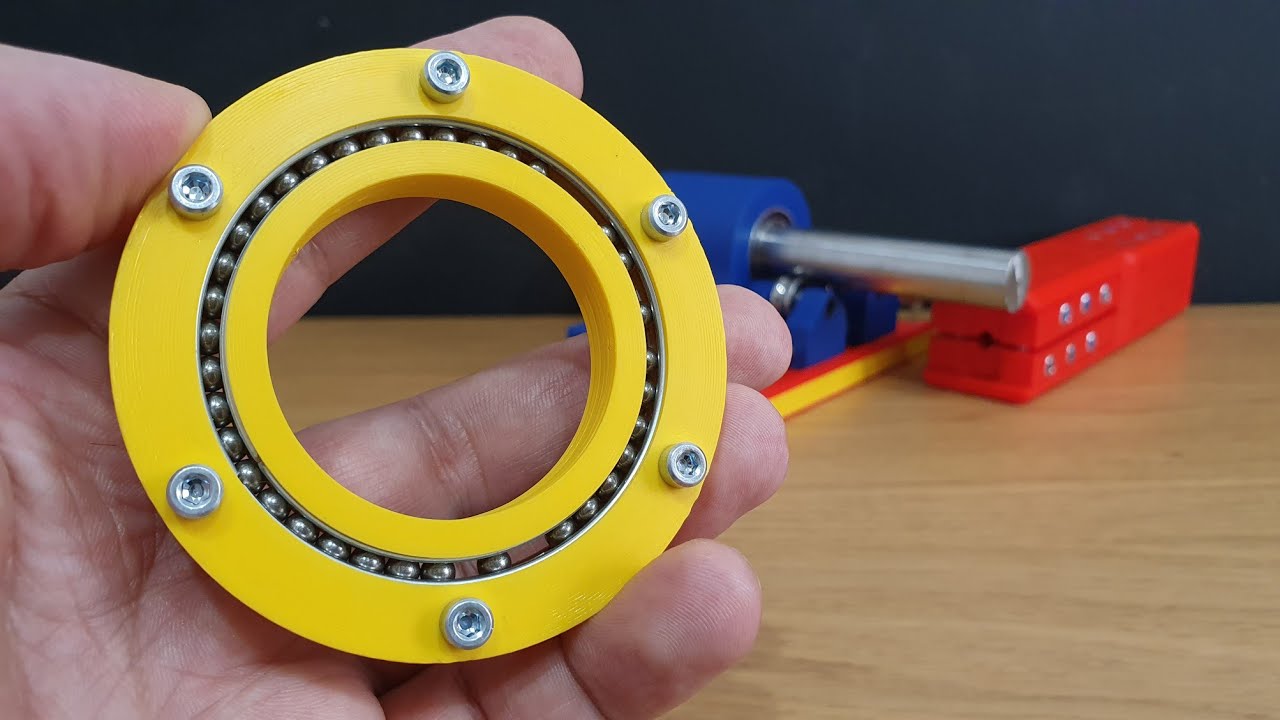

H-A-D featured this video recently, where carefully rolled wires were formed for the bearing races, and a bearing cage helped.

BBs aren’t made from the same kind of steel as bearing balls. I would expect spalling and/or fretting if the BBs are allowed to rub against eah other. A bearing cage (as shown near the end of that video) would be critical for even minimal bearing life if I’m right.

I’d suggest being 100% certain that you can’t get a cost-effective metal bearing set first. ![]()

The weird thing is, I am only going to use one BB and it will be rubbing on plastic.

What the heck? I was just informed that there are plastic BBs that Airsoft uses. I do NOT mean that I would be using a plastic BB. Zinc coated steel 4.5mm ultra smooth BBs from Daisy is what I have.

Did you guys actually think I meant that I would use a little plastic ball as a bearing? It seems at least one person thought that is what I meant until I talked with him a bit more about it.

No one here said anything about plastic BBs…

The geometry of using only a single BB isn’t obvious to me; it is a thrust bearing?

It is just a really smooth ball. I am placing it between the filament and a wall where I do not want rubbing friction. It should greatly reduce the friction. A roller is not an option for the position.

The drive gear and the BB will have filament between them. That would be considerable force against the wall without the BB there. Sadly, there is a chance that the BB will indent the wall.

I’ve been running a delta filament printer for years with nylon balls in the carriage bearings with good results…