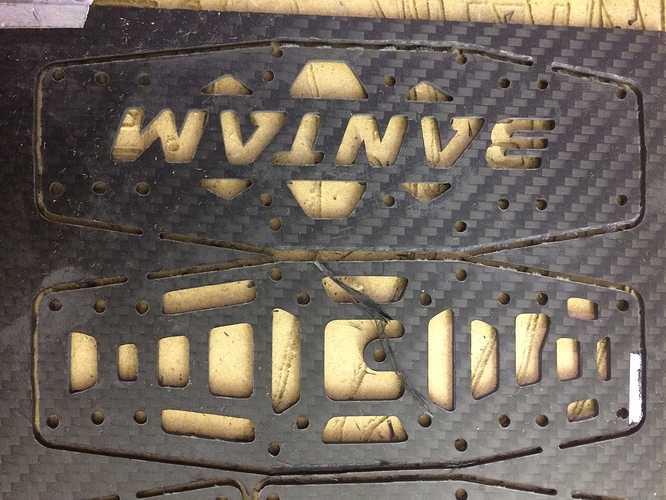

Back to the drawing board!!! My Ox started doing the same thing again sporadically shifting over mid cut. I have the 440.18 firmware on my TinyG now and thought that fixed the problem but that would be too easy.

How are you holding the stock down? Is it only the aluminum tape? Is the stock shifting during cutting or something?

It’s not shifting for sure. I’ don’t know what it is. Maybe the PC I’m running it with is not up to par some how?

Darn, that’s too obvious I guess. I use a pretty low end laptop on mine and it runs Xubuntu. It sure looks like a mechanical problem. I don’t think I ever saw, how do you tension your belts?

I do want to point out that any timing belt based machine is not giving you any mechanical advantage. Carbon fiber is one of the toughest materials out there. I have a 3040 to get the mechanical advantage of a lead screw. I believe we’ve all concluded that you’re only seeing this on one axis which means mechanical. It is almost certain your missing a step on your stepper motor at some point. Also, if you’re doing micro stepping that’s giving you even less torque.

@Steven_O_Neill can you shoot us a video of the problem happening? If you speed it too high, perhaps your belt jumping, but you’ll hear it.

How deep of a cut are you taking out of the carbon fibre?

no belt jumps I did feel a little thud when it would shift over felt like a bump. I was cutting 2 sheets of 2mm stacked on top of each other, I alum tape each sheet down securely, they do not move, not an issue. if the bit went off the edge of the carbon and had to dig its way back in at a shallow angle could this create enough resistance to hold the bit back some and reset the registration a few mm that way? I was cutting the 4mm of stacked CF in 3 passes of 1.54mm each to a 4.6mm max depth with my quiet cut spindle at 8000rpms

That seems like a very aggressive cut depth. When I cut mother of pearl for inlays I do 0.25mm per pass. What feed rate do you use?

100mpm

I was told by a seasoned veteran in this game that my bits are side cutter not tip so he mills like 6mm G10 in one pass but he has a 22000rpm router too so I know I can’t do that but try to shorten the job time down from 6 hours or so with 6 passes like I used to

The easiest thing would be to find a known good. If I were you I would cut my federated in half. Then see if it happens still. So what if its slow. I am 99% sure this is a mechanical issue. But to verify we need you to test. I agree that is a bit much to take away in 1 pass. As far as your veteran friend goes. Does he have the exact same machine and bit plus spindle?

Yeah brother agreed, 1.xx is a big cut! I’m in with these guys. Try 200mm/m travel, 4mm/m dive, .4mm depth of cut. Once you have one done, if it’s successful, start bumping up speed and bite.

It’s obvious by some of your small pockets you have tool flex or spindle and or z flex happening. Are you climb cutting only?

Even with wood I don’t normally cut more than 1/8 inch depth and I have pretty beefy steppers 383oz. I always cut counter clockwise with my bits rotating clockwise. I think 2mm passes on such rigid material would be pushing it with the OX. With that flex I still think your missing steps too.

I also have an ox and they are not designed well for hard plastics. I was able to cut perfect circles in wood. When I would switch to cast acrylic, the circle diameter would be inconsistent. Hard plastics are cut best at faster speeds but the ox belt system cannot handle the stress. The only way to counter this was to make small pass cuts of .3mm at slower feed rate and rpm.

I will try this, I must be stressing my steppers I guess.

Thats what I think is going on. Please let us know. I am making chips in some oak as I type and flying my fpv drone waiting for it to finish

I’m cutting that piece right now 200mpm and .6mm per pass 4 pass cut though 2mm CF 2.4mm deep we’ll see?

Successful so far. I’ll keep cutting shallow faster with more passes see if this the way to get good results with this machine.