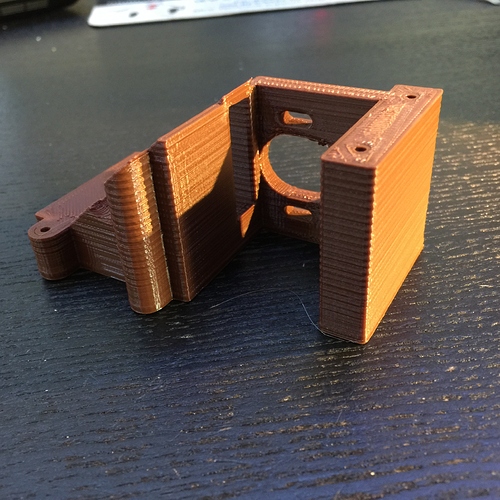

Any idea what is causing this? Is this a loose belt or some other setting?

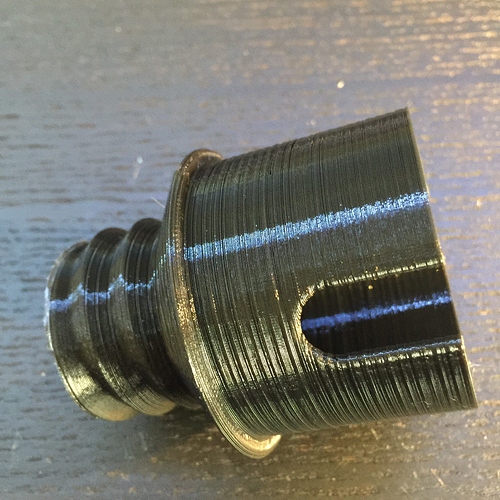

Looks like Z ribbing to me. Mind posting some pictures of your printer setup? Are your Z threads metric? Or imperial? How about the couplers you’re using? Some more information should be helpful.

Just took a look at your profile – Make sure your pulleys aren’t too close to the plastic and causing dragging. Make sure the screws aren’t bent. If they are, try removing the top binding them and let the tops swing freely and see if that helps any.

Zzzzzzz… If you take the part and place it against the z rail and it fits, it’s probably your z screw.

This is on a Printrbot Simple Metal.

Maybe it is my z screw that has come loose from the coupler. I will have to check that in the morning. The belts all seem tight.

I haven’t gotten the Eusthatios Spider V2 finished yet if that is what you saw on my profile.

Just a thought, try turning off Z compensation to see if it’s being caused by running the Z stage up and down for a very out-of-level build plate.

The direction of the ribbing is important. Print a test cube, thin wall is fine. Note if the ribbing is protruding on the x axis, or y axis. Which axis is it more prominent (a test cylinder would work too).

This will tell you if your leadscrews are bent or if it is a belt problem. If it happens on both axis in a helical (like a screw thread) mannor (on a thin wall test cylinder) then either your leadscrew is bent, or the coupling is bent and off-center. If it happens only on the x or y axis, then the corresponding axis has an issue, like backlash, a slipping pulley, missing steps, etc.

@bcrazycramer Check if your z screws are straight and/or located true in the couplers. If not your couplers may wobble and cause the effect you are seeing on your prints. @Mark_Rehorst You do of course need the thread pitch to determine steps/mm

Check over extrusion. I had very similar results before tuning my esteps further. If you are extruding a little too much then it can get pushed around by the nozzle and build up between layers resulting in a regular ribbing that will be different depending on the perimeter distance of the part. I diagnosed this by printing two different sized cylinders at the same time which showed different ribbing periodicity.

I had a similar problem on my printer and it turned out to be due to the fan cooling the print, as weird as it may seem. I first thought it had to do with many of the same problems already explained above, but I couldn’t seem to correct it until I changed the way the fan was cooling the print. I even went so far as to buy a new printer, and I still have the same problem, but it is not noticeable that much. The problem is also more pronounced with a smaller layer height. I was using a .35mm tip at .15mm layer height and going to .2, .25, and .3 seemed to make it progressively better. Ultimately though, having even cooling all the way around the tip fixed the issue.

Looks like the Z Coupler was loose. I tightened it up this morning. I will have to wait and see if it helps.