Along with a couple other folks from the community, i received my E3D ( http://www.e3d-online.com/ ) hotend this week. I opted for the 3mm unassembled version, planning to print ABS, Polycarbonate and maybe Nylon with it.

Let me cut straight to the point: In my opinion, this is the best hotend money can buy right now. It is well designed, beautifully machined and, as expected, is generally a very precise hotend. Oh, and did i mention it’s only £39 (+ s&h), which is about as much as you’d pay for a regular Jhead?

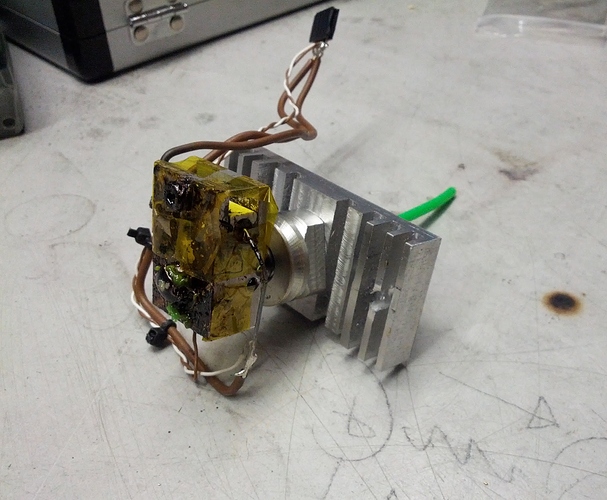

Assembly was a breeze - the only finicky part is covering the thermistor legs with kapton, the rest is screwing the parts together. Not much to go wrong there.

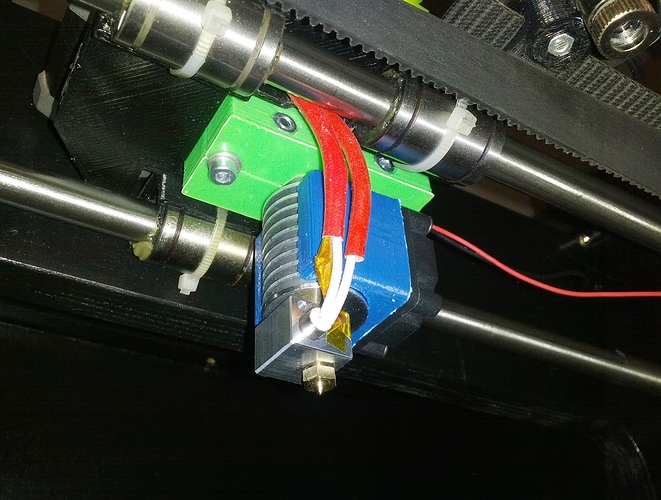

Since i don’t have a groovemount extruder and didn’t want to print one, i made a clamp from thermonuclear green ABS. As it turns out, the top of the hotend doesn’t get warm at all, so PLA extruder bodies are totally fine as well - many conventional hotends have thermal issues at their tops, often melting the carriage or extruder. Not this one.

The 40W heater cartridge heats up insanely fast and has, of course, no issues at keeping its temperature. I’d think you could have a fan for PLA printing blowing right at the hotend without it batting an eye.

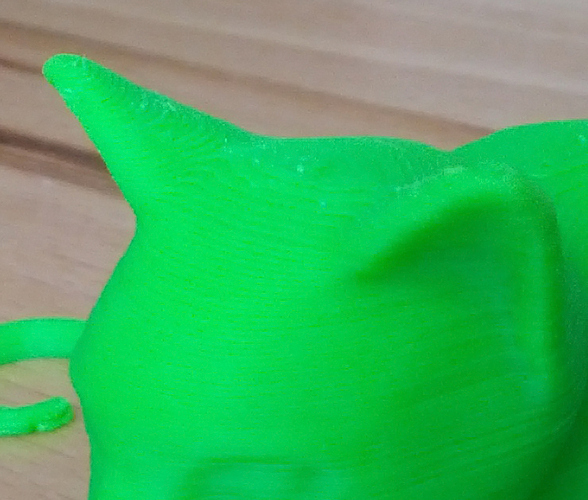

Now, when i say precise, what i mean is that the hotend does not significantly ooze but does respond quickly to changes in feed rate - so transitions to the outer perimeter leave no blob at all, tiny details come out nicely and support material looks like a gift from heaven.

On the downside, the fan is rather noisy and unfortunately get my wooden Mendel90 oscillating in certain spots. This might be an issue for folks printing in their living room, but i have my printer in the basement / workshop, so it does not bother me personally.

Like i said, this is my new favorite hotend. Great job @Sanjay_Mortimer and @David_Lamb !