Again, about extruders, which are more properly called “feeders”…

This started as I had fabricated a filament-out sensor, but felt this should be an integrated part of the filament feeder. Also I am starting to suspect the Bowden feeder on my printer with a 0.8mm nozzle on a V6 hotend might just be running out of torque.

(And I have not yet added the “Volcano” kit.)

So I need a better feeder, with an integrated filament-out sensor.

If you are buying stuff off the shelf, buy a Bondwell “extruder” and just deal with the not-integrated filament sensor.

My interest is in something better.

Digging back, I found two interesting examples.

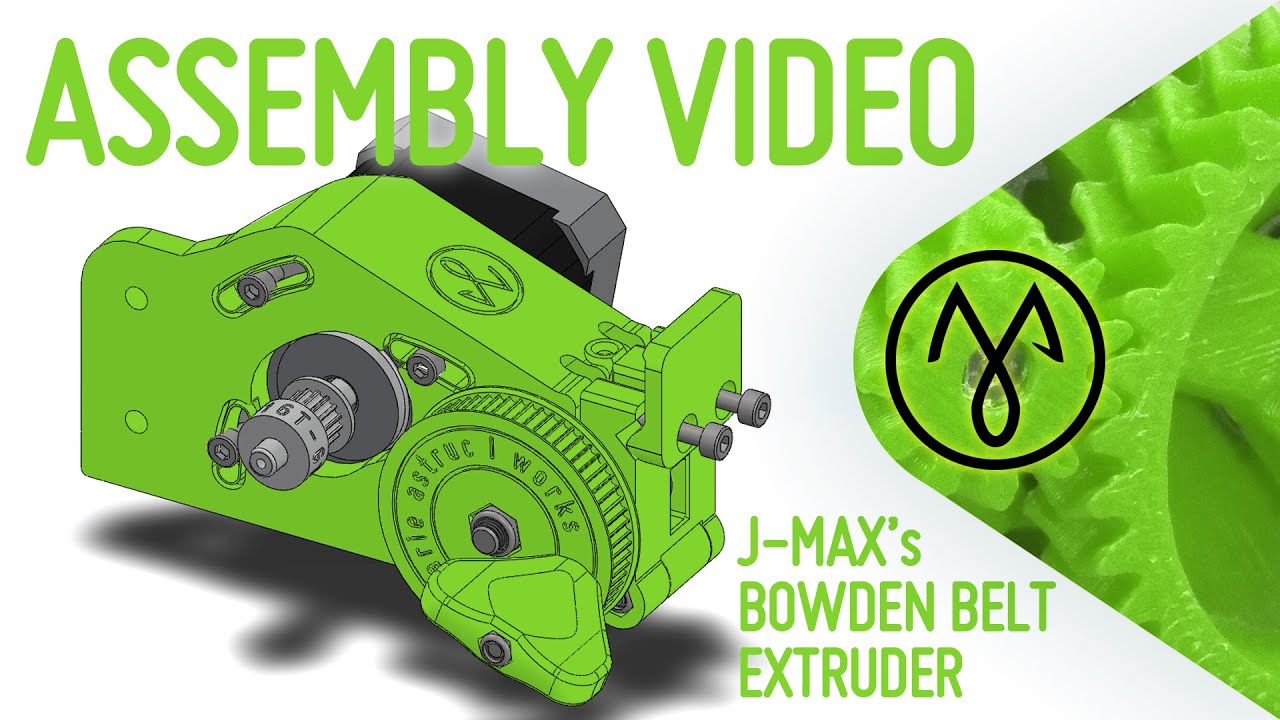

J-Max

http://www.j-max.fr/?p=632

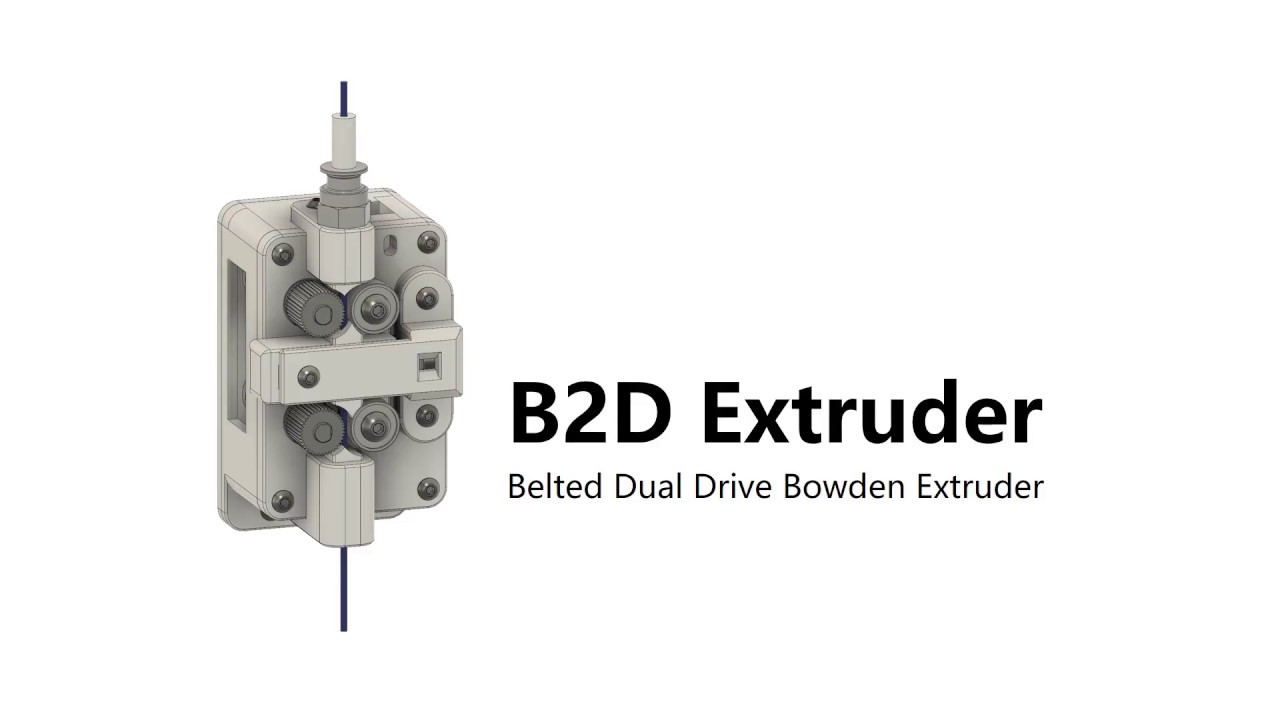

B2B Extruder

In both cases, a belted (geared) feeder, that could potentially generate a lot of torque with a smaller (and lighter) motor.

Wondering if I can design something more compact, using the existing examples as inspiration…