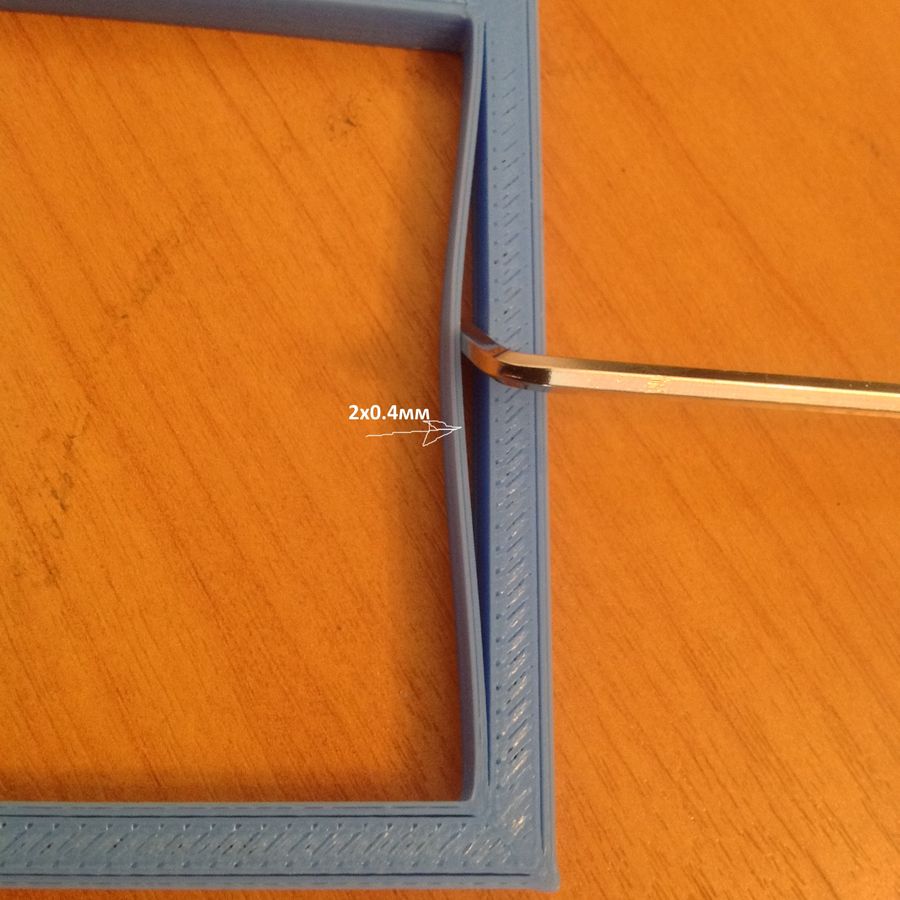

After some experiments, I finaly found proper printing settings. But there is one problem I can’t solve (yet?). Seemls like external layer of my print not “glued” strong enough to the “filling”. On which setting this depends? I’m using Sli3er.

Infill/perimeters overlap, under advanced. 15% is default.

You may have slight underextrusion tough, as your top layer has small gaps.

Thankks, will play with this.

It’s better to print only with 2 permieters… this happens if you print with 3 or more.

@Andreas_Holldorfer I disagree, but it may be dependent on nozzle size, layer height and mainly extrusion width.

For parts that require structural solidity I use 5+ perimeters.

I was thinking so to (the last 5 years or so) but recently I learned more about the material science and the result is now I just print 2 perimeters and increase the infill. Thanks to slic3r I can do this locally. I also took a look at a lot of professional machines and they also use 2 perimeters.

This is a mater of how the material cools and how fast you print. If you print all the perimeters very slow (about 30mm/s) It is no problem. If you start printing the inner perimeters faster and the outer slower they tend to separate.

OK, so I set overlap to 20% (from default 15%). Now it seems to be OK, right?

Also I noticed my PLA thread is not 1.75, but rather 1.5mm, so I changed this setting in Sli3er too (does it actually have any effect on print settings? Not sure).

Changing the filament size in Slic3r absolutely has an effect and is very important. In your case it will mean that much more material is extruded, and it explains why the first print was underextruded. I would try to set overlap back to 15%.

@Andreas_Holldorfer That is interesting, I will keep it in mind, though I have not had any problems with it so far.

Vladimir, i would be careful playing with perimeters for a bit. You had bad feed rate before which you fixed by switching from 1.75 to 1.5, but it is very likely still not properly calibrated.

Most prints should work with 2 perimeters and 15% overlap. If they don’t, look at the feed rate first.

You didn’t mention your printer type, if you have anything like short belts you also might want tighten those.

Yeah it looks like you need more infill overlap. Should solve the problem

Start with calibrating your extruder first. Everything else will be off if this isn’t correct.

I totally agree with the comments above as a possible solution to this serious fault.

Having said that the print looks perfect except for this.

If you still wanted to use it, then as I have done in the past, used ABS Solvent Cement, plumbers or hardware store. It does give a really very strong bond and saves wasting time reprinting.

As I said, I’ve used it several times to fix minor problems.

Lets me move on to the next item. This does not fix the issue but does save the part.

I have similar problems when printing at higher speed, although not so severe. I’ll have to check the Infill/perimeters overlap too. Thanks for the tip!

It seems like you did things in the wrong order but still ended up with a working print. If you wan’t to better calibrate your printer, first calibrate the extruder, make sure the filament diameter is correct, then check infill overlap. Also, it looks like your corners are a litle wonky; the outside corners buldge out and the inside corners buldge in, is this a design feature or a problem with the print?

This is problem with print, yes.I don’t know how to fix it yet. As for layers, as I mentioned before, I returned overlap to default (15), and just set correct (real) filament diameter, and this problem with layers is gone. Also I don’t know how to “calibrate extruder”. There is some topics in the Internet, like measure 10cm of filament and make printer to feed exactly 10cm into extruder, and calculate the difference, and write it into EEPROM of the board. But since I can’t write in EEPROM for some reason, I can’t do it yet…

Not being able to write to EEPROM is either due to not understanding how to or because your control board doesn’t have that ability.

Have you managed to use a terminal to talk directly to the printer? (Send gcodes directly)

Theres a pretty good calibration guide around … http://reprap.org/wiki/Triffid_Hunter’s_Calibration_Guide

Good luck! Ask a lot of questions

@Vladimir_rvo_va_r Try this video for extruder calibration if you have access to your printers terminal. As for the corners, your belts might not be tight enough or you may need to calibrate your X and Y axes.