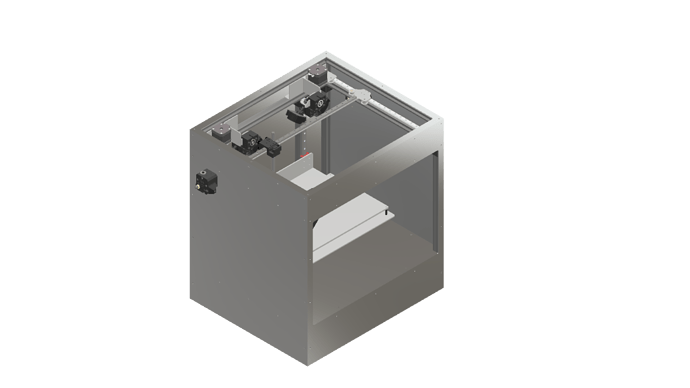

A quick render of a Printer I’m working on. CoreXY based tool changer. Build area of 300x200x200 running on rails and custom laser cut aluminium parts with very few printed parts. Will be running on Klipper firmware.

Where you getting your parts lasercut? Everywhere I looked the costs were around 400 for a single panel.

@Stephanie_A - I’m an assistant product designer and Laser Programmer by trade, and have a 4kW industrial fibre Laser at my fingertips at work as well as a full fabrication shop. As such I get things at cost. Although if you’re in the UK I’d suggest looking at Yorkshire Profiles as I got a full set of plates for my Delta for around £70

MDF/plywood would also work i guess?

Have a CoreXY made from lasercut 6mm MDF and the price was about $10 for material plus membership cost ($30/month) at my local makerspace that has a 100W Laser.

@Johan_Jakobsson for the cladding possibly, although I’d probably go Acrylic sheet as it’s thinner. However, there are a lot of bent ali parts so they’d need to be redesigned into printed parts

Sorry I’m in the USA. That would be a great price though.

I’m itching to make a printer similar to @Daryl_Bond derivative of Rene Juracks DICE printer https://github.com/darylbond/DICE200

Just with direct drive extruder.

https://github.com/darylbond/DICE200

I would try to follow the example of e3d and use a belt path that avoids the top front cross member, it gets annoying not being able to reach straight in.

@Stephanie_A take a look in v2 of my repo for a direct drive

@Daryl_Bond I’ve not looked at E3D’s design that closely. Part of the design choice of this was to try and hide the belts, partially aesthetic, partially safety. Which has been partially achieved, but the rails in the way for the sides to do so.

For those interested, it’s designed in Inventor 2019 with a full pack and go available at https://github.com/AxMod3DPrint/AX-01

https://github.com/AxMod3DPrint/AX-01