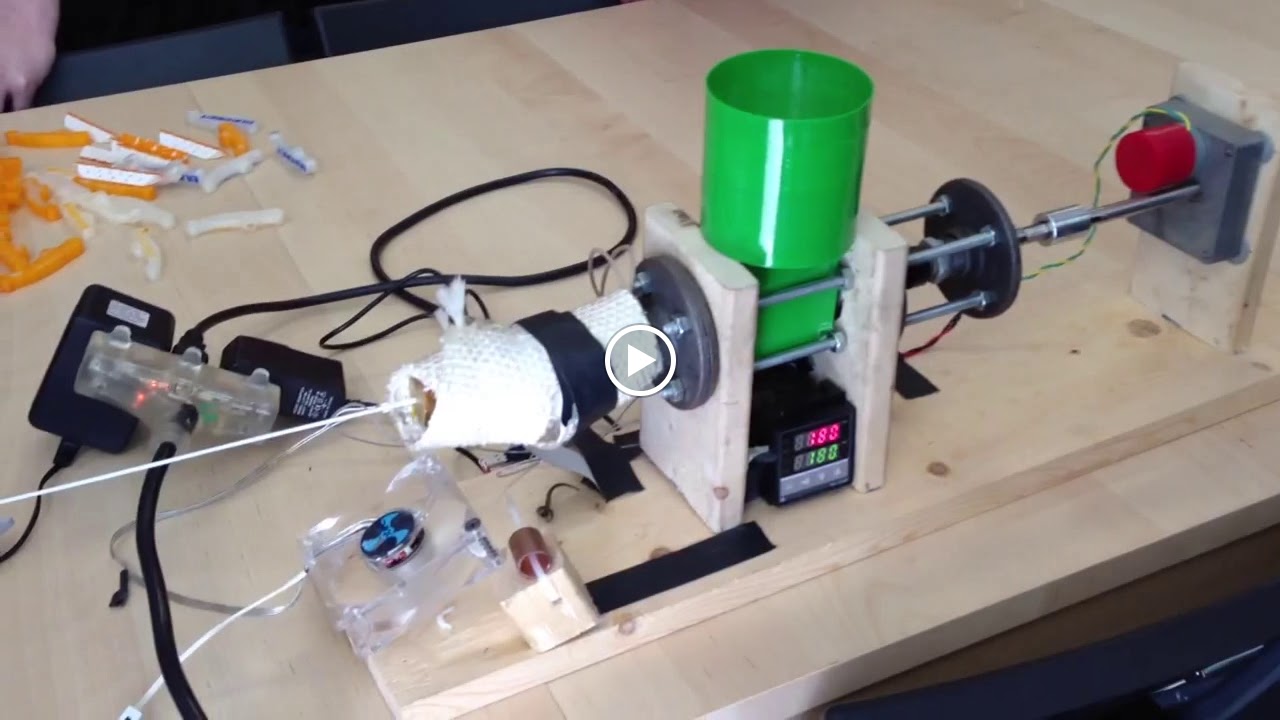

A prototype #filastruder brought to the 3d printing monthly meetup at #deezmaker shop by @Ian_Johnson

Did it extrude reliable material for printing or did it feel flimsy/inconsistent?

It was surprisingly good. Needs more precision but a great start.

What kind of auger does that use?

It’s an ordinary auger that you would buy at the hardware store, which fits in a 1/2" black iron nipple. The extruder by itself can do +/- .05mm if you let it extrude onto the floor, but the winder isn’t consistent enough yet to maintain that tolerance while stretching the filament. I’m working on using a slightly modified Wade’s extruder to draw the plastic rather than the DC motor and latex rollers. It won’t have a hobbed bolt of course, I don’t want to put teeth marks in the filament.

I’ve often wondered how consistent the extrusion pressure is with a single screw. What keeps the material moving forward rather than just spinning around with the auger.

The flow of unmelted pellets forced in by the auger keeps the pressure up, and forces the melted plastic to keep flowing rather than sticking to the auger. There is also zone of melted plastic between the auger and the die. So long as the amount of pellets being delivered is consistent, the pressure should stay constant as well. I think slight variations in the speed of the auger and # of pellets tends to be absorbed and averaged out by the melt zone.

is there an issue with gasses that build up making your filament porous?

I don’t think air is really a problem. There is enough pressure in the melted plastic that it is likely forced out the back. Steam from moisture in the plastic might be an issue. It is recommended that you dry the pellets right before you use them, so a dehydrator would be a good accessory for this. There is usually a lot of bubbling when I start it up, but I think that is from air drawn in through the die when the plastic cooled getting mixed in when it heats back up. It works its way back out pretty quickly.

Good job, I’m a fan. I’d love to build one. Do you have a materials list?

I don’t have a materials list, but you can contact the developer, Tim Elmore at filastruder@gmail.com. He’ll let you know when he’s ready to send out more kits. It’s actually a bit cheaper to go with kits due to the shipping. Also there is an ongoing thread on it at http://www.soliforum.com/topic/557/filament-extruder-convert-pellets-to-filament/