A Love Story

My wife, a mathematician, asked whether I could machine some intransitive dice for her. She had in mind simple six-sided dice:

Consider the following set of dice.

- Die A has sides 2, 2, 4, 4, 9, 9.

- Die B has sides 1, 1, 6, 6, 8, 8.

- Die C has sides 3, 3, 5, 5, 7, 7.

The probability that A rolls a higher number than B, the probability that B rolls higher than C, and the probability that C rolls higher than A are all 5/9, so this set of dice is intransitive. In fact, it has the even stronger property that, for each die in the set, there is another die that rolls a higher number than it more than half the time.

(Yes, this is kind of like “rock paper scissors”)

Note that the numbers on each die add up to 30, and that each number is repeated once.

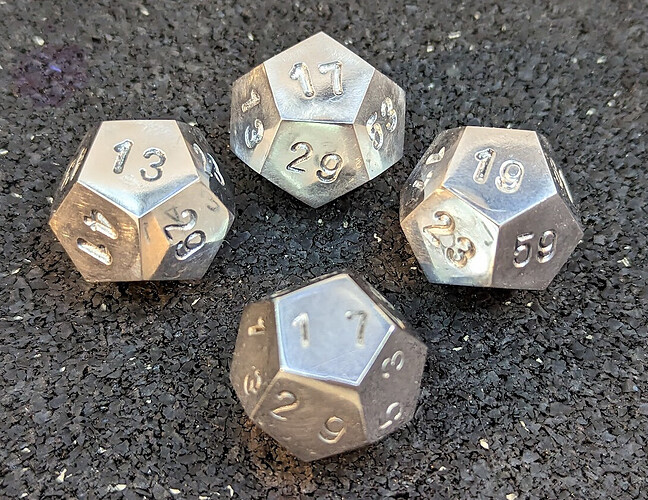

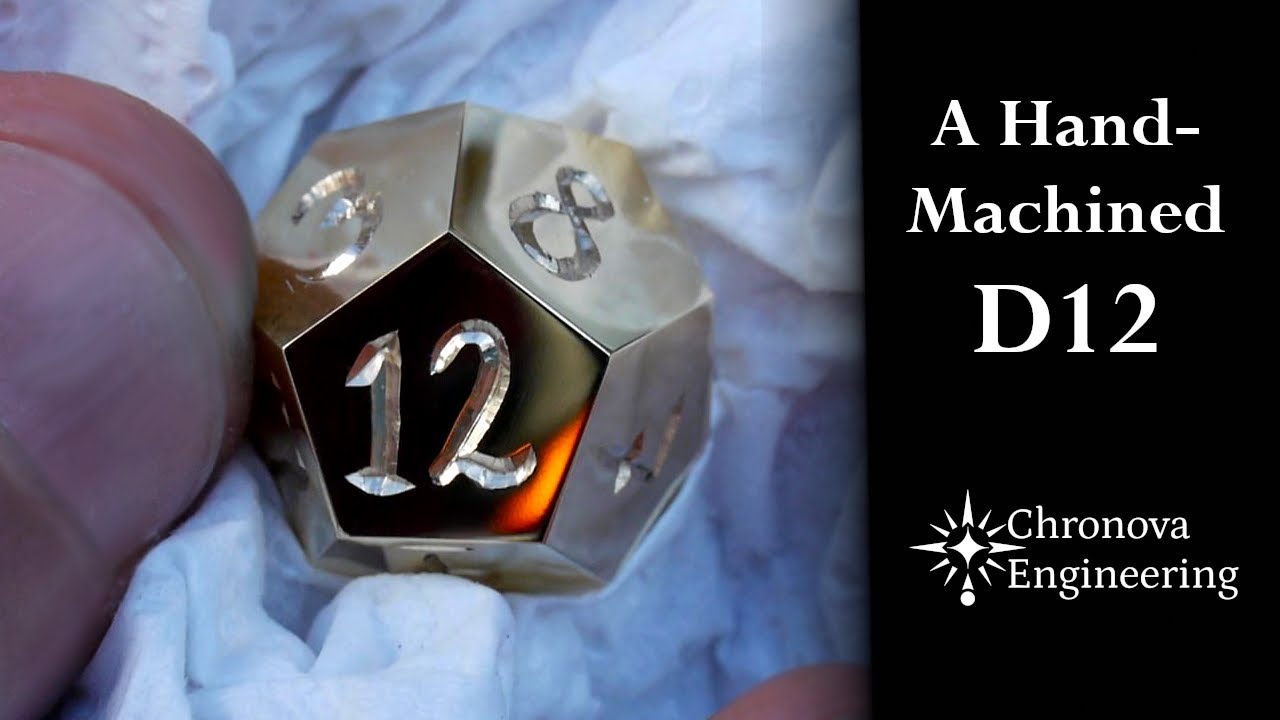

I noticed, though, that there was another set for which each die has no repeated numbers, all the numbers are two-digit primes, and they still each add up to the same number. It’s a bit more of a challenge, though, because they are dodecahedra.

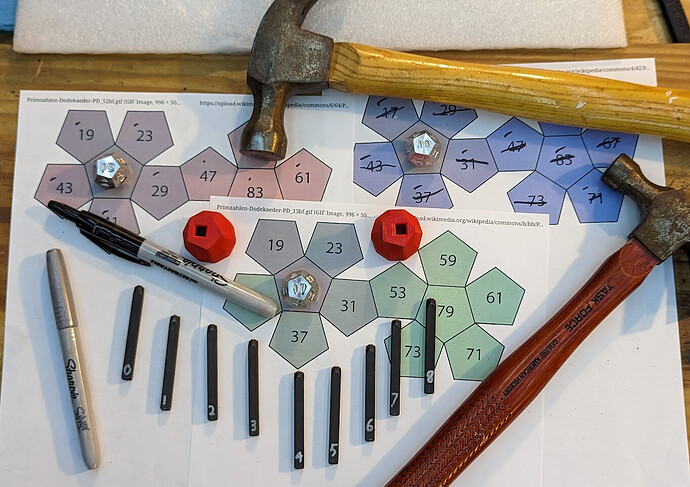

It is also possible to construct sets of intransitive dodecahedra such that there are no repeated numbers and all numbers are primes. Miwin’s intransitive prime-numbered dodecahedra win cyclically against each other in a ratio of 35:34.

Set 1: The numbers add up to 564.

| PD 11 | 13 | 17 | 29 | 31 | 37 | 43 | 47 | 53 | 67 | 71 | 73 | 83 |

| PD 12 | 13 | 19 | 23 | 29 | 41 | 43 | 47 | 59 | 61 | 67 | 79 | 83 |

| PD 13 | 17 | 19 | 23 | 31 | 37 | 41 | 53 | 59 | 61 | 71 | 73 | 79 |

I decided that I had a Valentine’s Day project to start.

The only question was whether the dice were a valentine’s day gift from me for my wife, or the shop time was a valentine’s day gift from my wife to me! ![]()

A Machining Problem

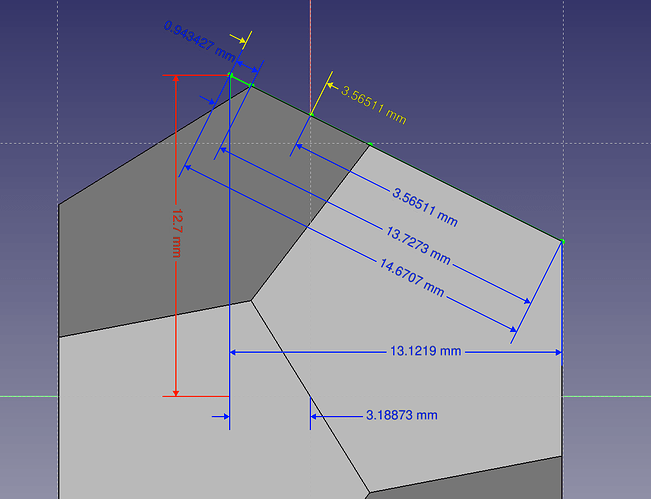

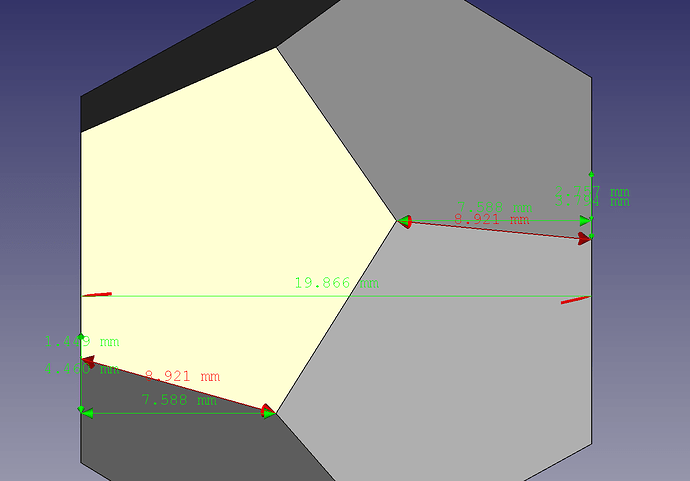

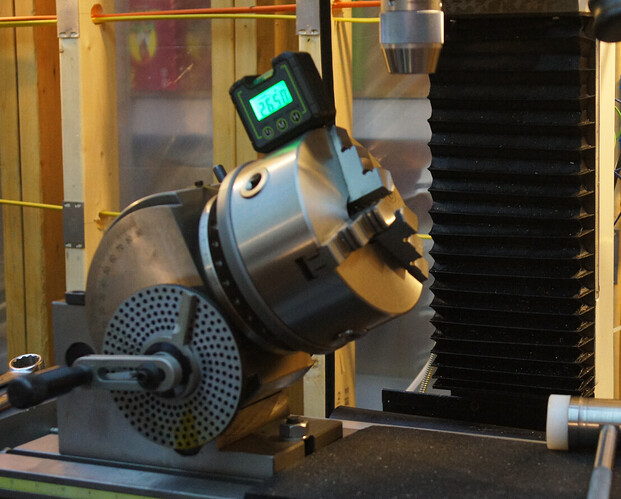

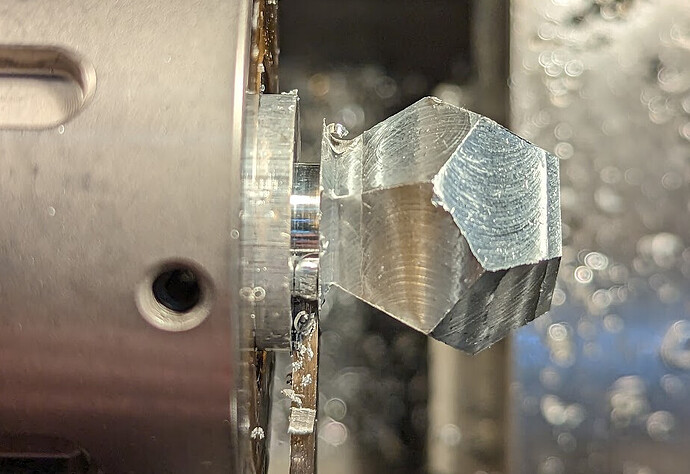

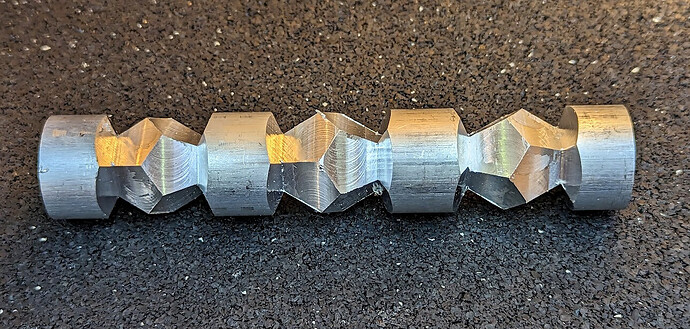

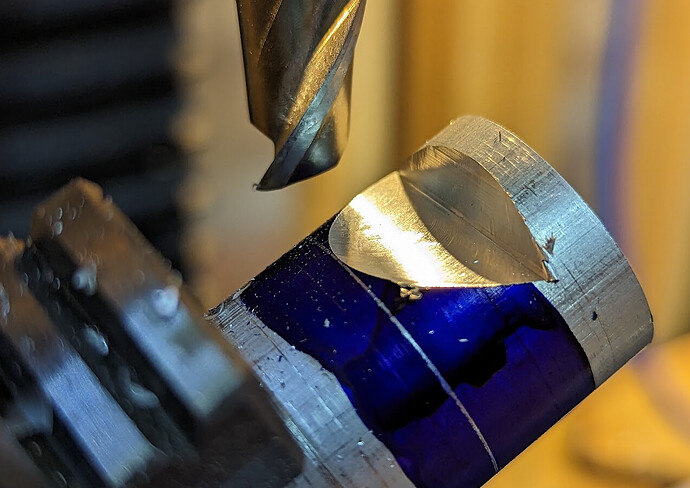

Dodecahedra do not have 90° angles anywhere. The angle between faces is about 116.5°, and machinists like 90° angles. I used the FreeCAD Pyramids and polyhedrons Workbench to work out angles and sizes and got to work.

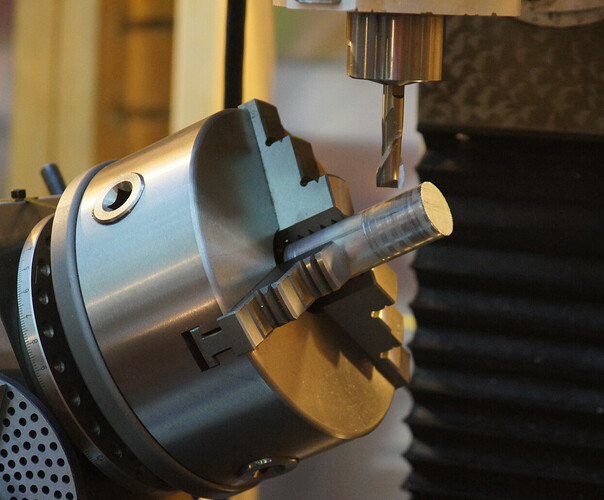

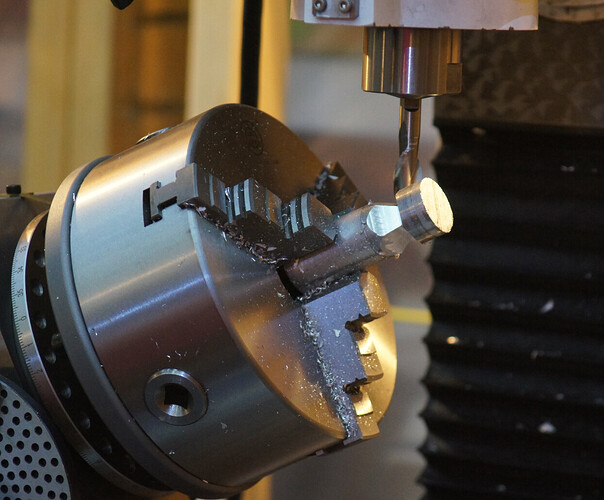

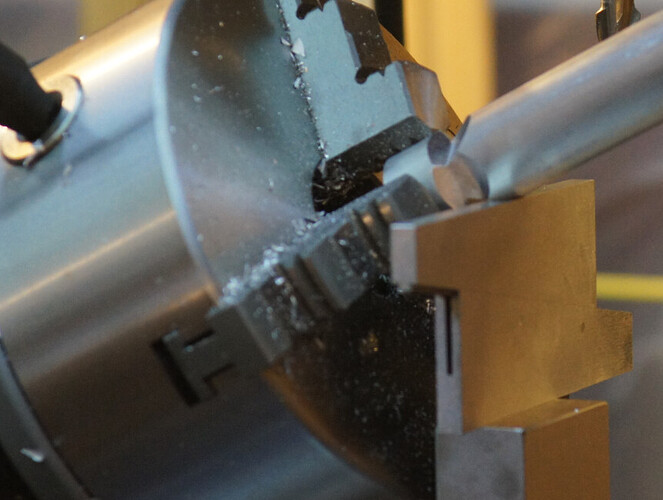

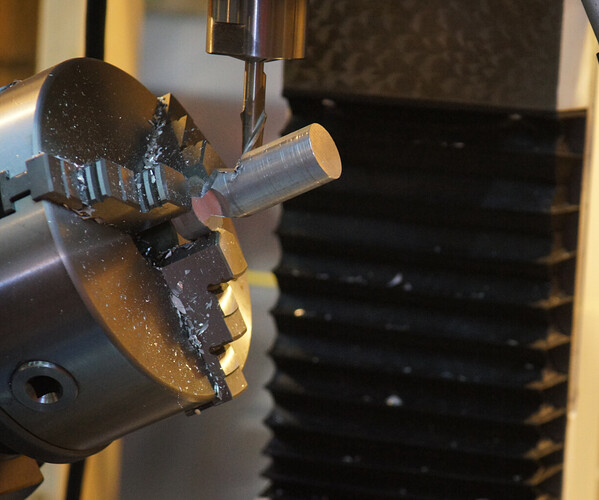

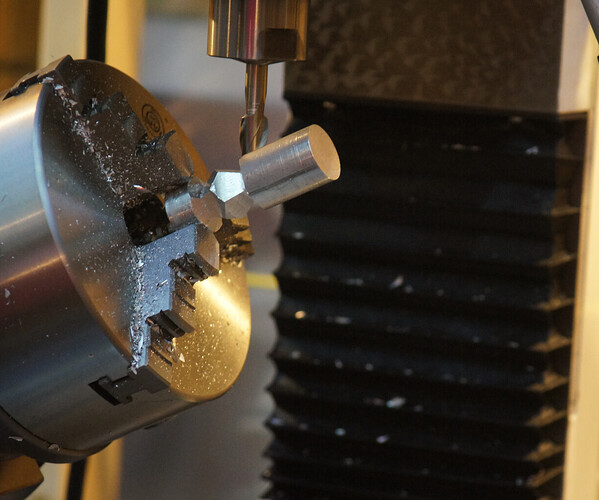

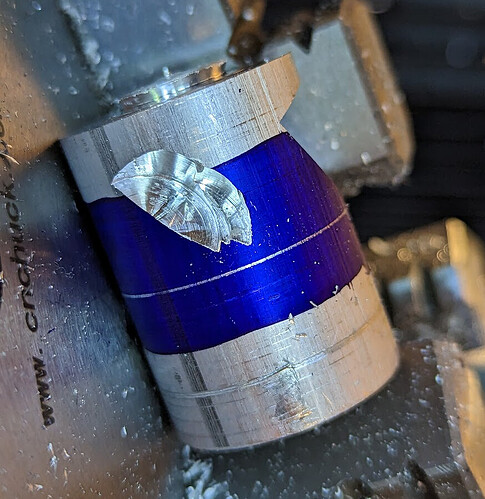

- Set the dividing head set at 26.5° (116.5° - 90°) and put 1" aluminum stock in it

- Cut every 72°, 15mm from the surface of the stock

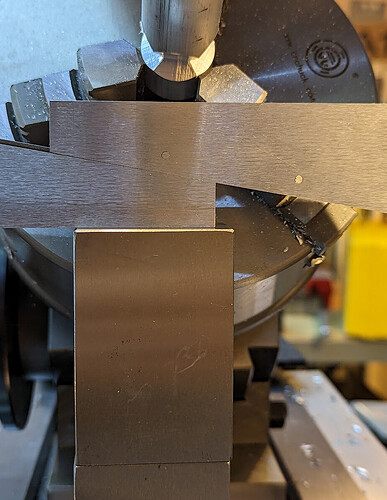

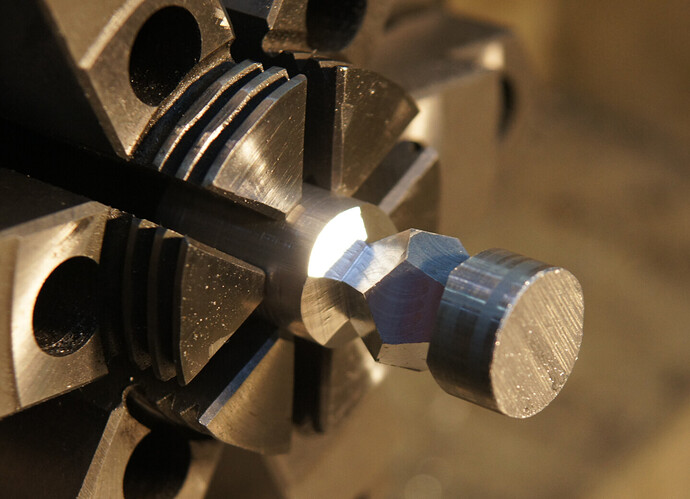

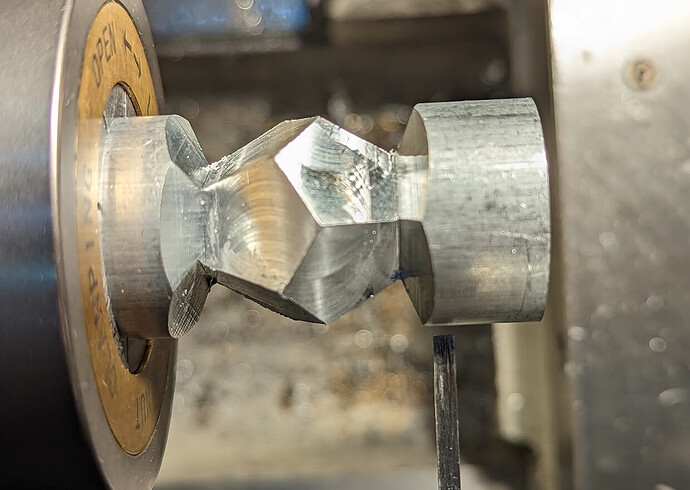

- Reverse stock, use an adjustable parallel to line up a cut face parallel to the table, then cut down to 19.87mm between the new face and the opposite face aligned with the table and 14mm in from the vertex that is formed

- Again cut every 72° to measure across opposite faces

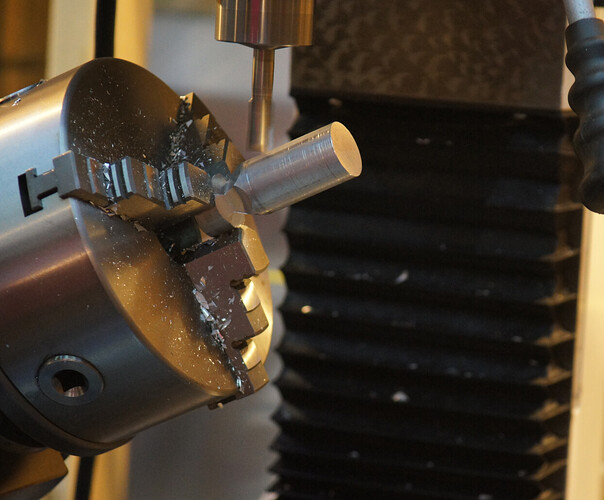

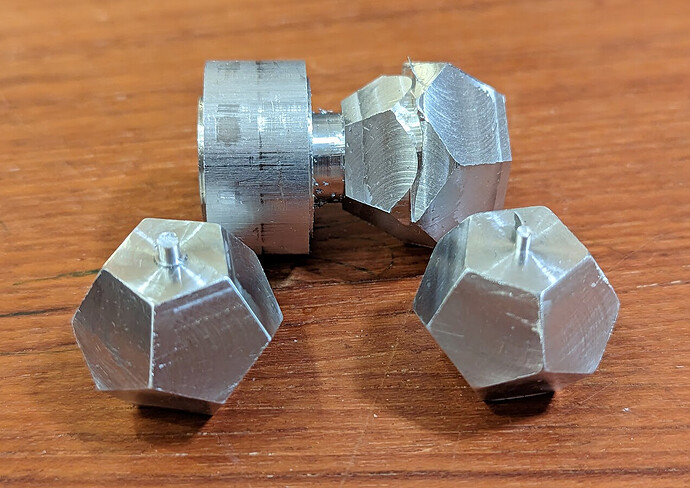

- Transfer to lathe, face off one end 7.59mm from a near vertex, then part off to length 19.87mm

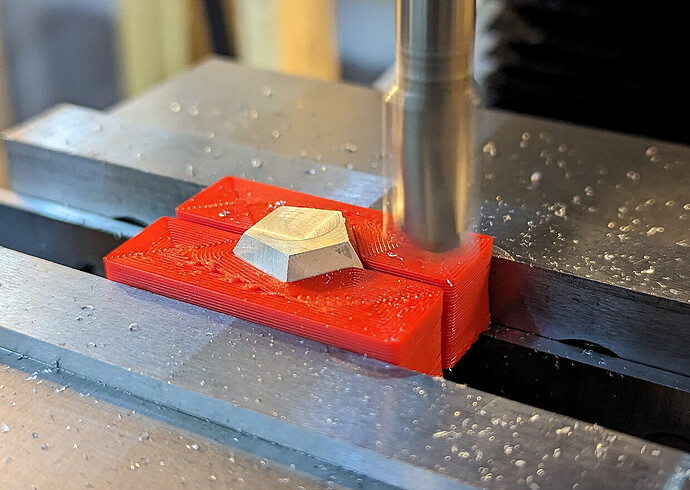

- File off the parting nub, or print soft jaws to hold the dice in place to mill off the parting nub. I tried both, and settled on the soft jaws. Printed in PETG with all perimeters and 90% extrusion for high strength.

I discovered that I could make all three dice out of a single rod about 120mm long, as long as I didn’t make any mistakes. (I did make some mistakes, sadly.)

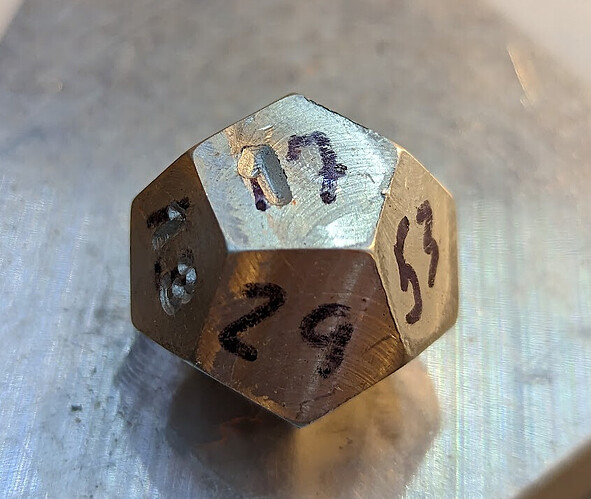

Then I 3D printed two alignment guides to hold punches, and punch the numbers into the faces. I designed these guides in FreeCAD, which actually made it pretty easy! ![]()

Of course, punching the numbers in distorted them a bit. I colored the faces with sharpie, wet-sanded them with oil down with 500 grit sandpaper on a flat block until the sharpie was gone, then cleaned them and did the same with 1200 grit, and finally polished them all over with Mother’s Mag and Aluminum polish, and cleaned them thoroughly.

Then I used 1ml syringes to put tiny drops of Testor’s enamel into the stamped numbers, wiped off some of the excess, waited an hour or so, and then used paper towels and fingernails to clean the enamel off the polished surface, leaving the enamel in the stamped number. I used different color enamel for each die, so that you can tell the precedence between the dice: Blue beats Red, Yellow beats Blue, and Red beats Yellow.

By Valentine’s day, the enamel should be fully cured!

IntransitiveDice.FCStd (636.1 KB)

PunchGuides.obj (710.7 KB)

SoftJaws.obj (158.6 KB)

Build log with lots of pictures to follow!