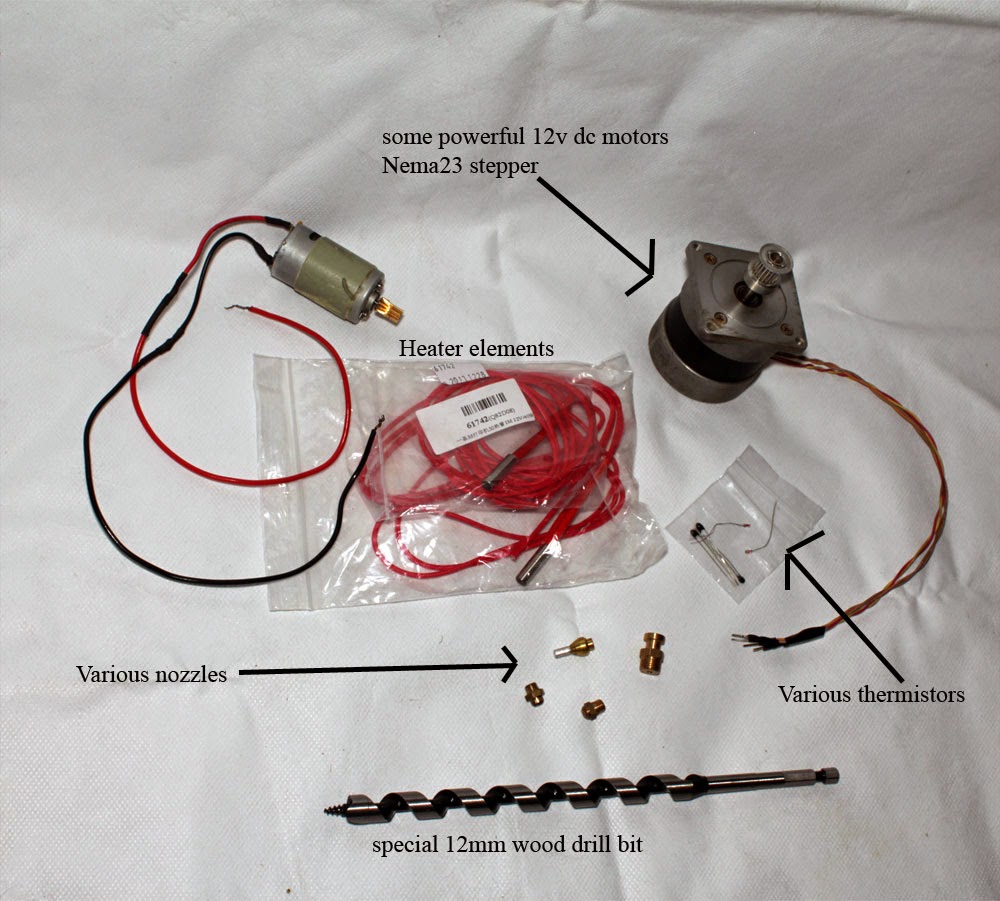

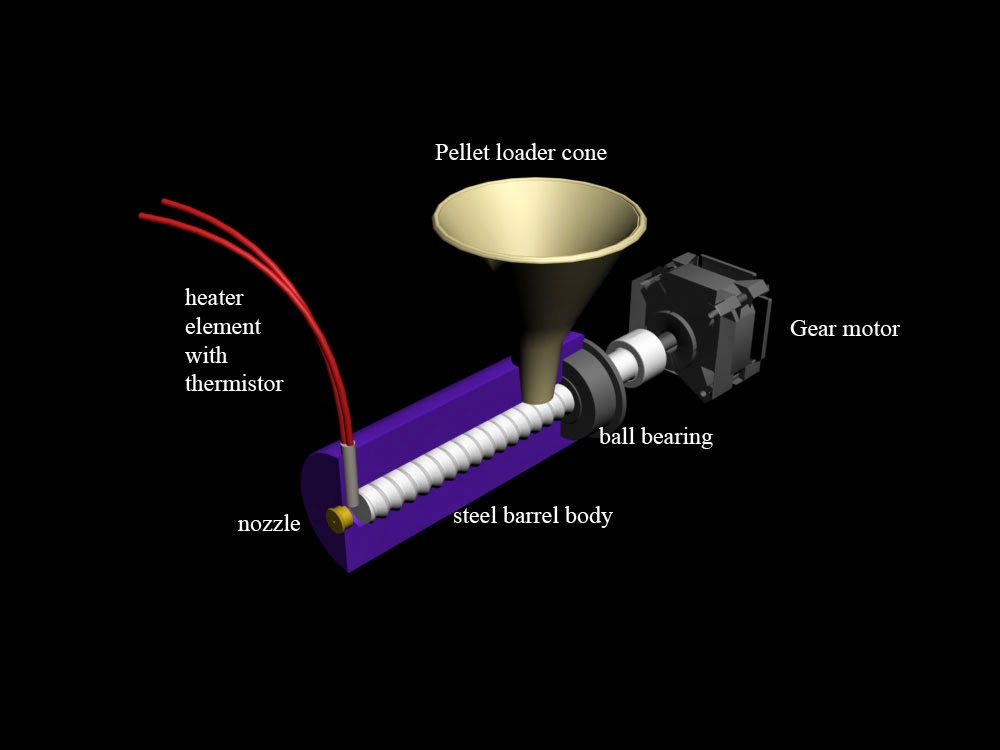

A homemade filastruder project… Details on my site at:

http://dh-sims-site.com/repstrap_3Dprinter.html

Looking forward to your experience / experiment. I’ve wondered about how these extruders avoid bubbles in the filament - I can see air pockets between the pellets getting trapped as they melt and being forced along and out the nozzle thereby creating defects / inconsistencies in the filament being extruded.

Air pockets don’t get trapped because the melting rate and local velocities are so low with home based extruders.

Dincer, in my experience Nema23 motors have about 1-2Nm of torque. Also in my experience, you need around 6-8Nm.

Source: created the Filastruder.

Thx Tim,

I was not also sure about nema23 stepper usage, I think I will decide on using a more powerful dc gearmotor (like car windshield motor) or will give a try to my household drill…

650watts is more than enough, 200-300watts even at slow speed…

Household drill is far too fast, you need speeds of around 5RPM, not 1500.

yes I know, I was talking about a drill with speed control… screwing mode… these deliver low torques at low speeds but 200-300watts even at low speed…